This vital overview provides a detailed insight to aluminum panels. Discover the benefits of employing aluminum panels in a variety of applications, including its durability, versatility, and aesthetic appeal. Learn about the installation process and the most important factors to consider for a successful installation. Whether you’re working on a residential or business project, this guide can help you make better decisions. Aluminum panels provide great performance and sustainability for a variety of applications, including roofing and cladding. Dive into this invaluable resource to realize the full potential of aluminum panels and produce remarkable outcomes in your construction projects.

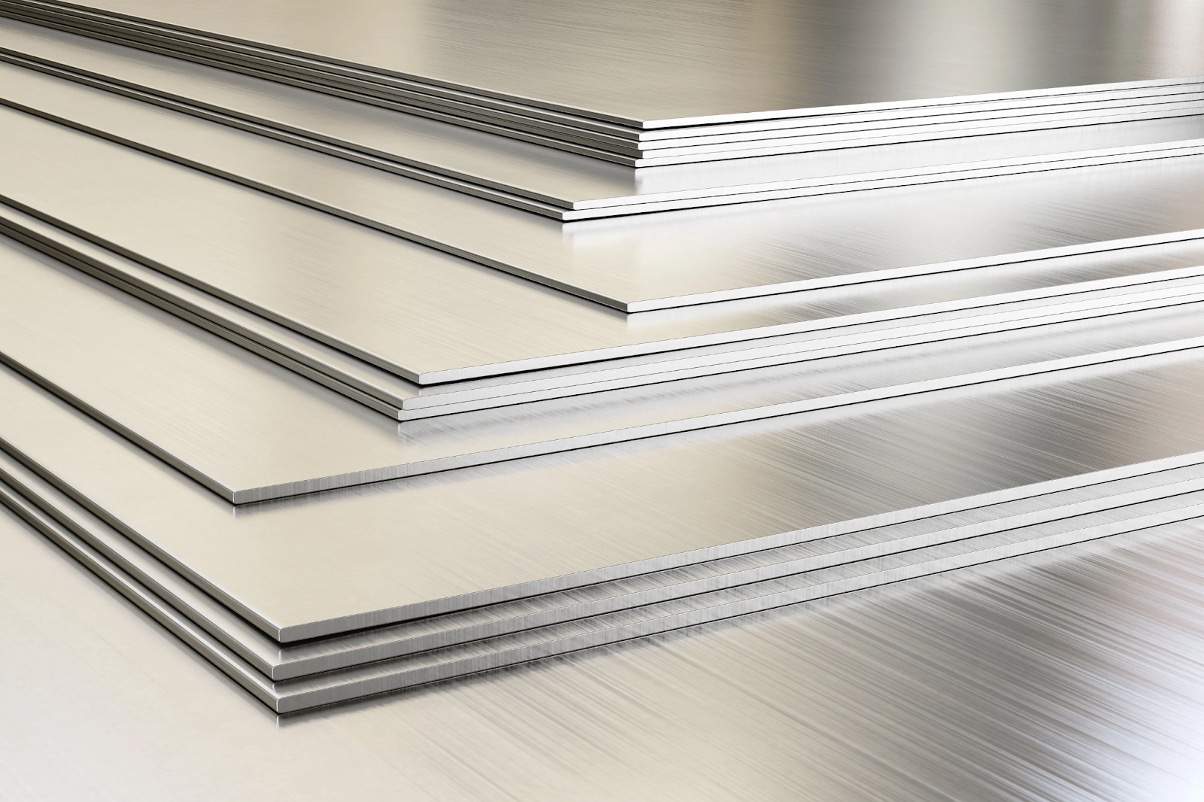

An aluminum panel, also known as an aluminum sheet or aluminum plate, is a flat, thin, and rigid sheet made primarily from aluminum alloy. It is a versatile material widely used in various industries and applications. Aluminum panels are produced through a process of rolling, where aluminum ingots are passed through high-pressure rollers to create a flat and uniform sheet.

Aluminum panels offer several advantages, including lightweight construction, excellent corrosion resistance, high strength-to-weight ratio, and ease of fabrication. These panels can be easily cut, bent, drilled, and shaped to meet specific project requirements. They are commonly used in architectural and construction projects for building facades, roofs, wall cladding, signage, and interior design elements. In addition, aluminum panels find applications in the automotive, aerospace, marine, and electronics industries due to their desirable properties and versatility.

Aluminum panels for roofs offer several distinctive features that make them a popular choice in the construction industry. Some key features of aluminum panels for roofs include:

Aluminum is known for its low density, making it significantly lighter than many other roofing materials. This characteristic simplifies transportation, handling, and installation processes, reducing labor and equipment costs. Moreover, the lightweight nature of aluminum panels puts less stress on the building’s structure, allowing for more design flexibility and potentially lowering construction expenses.

Aluminum roof panels are highly durable and resistant to various environmental factors. They have excellent corrosion resistance, which helps them withstand exposure to moisture, chemicals, and atmospheric pollutants. This corrosion resistance ensures that the panels roofing maintain their structural integrity and aesthetic appeal over an extended period. Furthermore, aluminum is not susceptible to rot, insects, or fungal growth, providing additional longevity and reducing the need for frequent repairs or replacements.

Despite being lightweight, aluminum roof panels exhibit impressive strength. They offer a high strength-to-weight ratio, meaning they possess considerable load-bearing capacity while minimizing the overall weight burden on the roof structure. This aspect is particularly advantageous in regions prone to heavy snowfall or seismic activity, where the roof must withstand significant loads.

Aluminum panels roofing are designed to be weather-resistant, providing reliable protection against harsh elements. They are inherently water-resistant, preventing leaks and water penetration into the building. The panels’ roofing are also engineered to withstand temperature fluctuations without warping or cracking, ensuring their structural stability and performance in extreme climates.

Aluminum roof panels offer versatility in terms of design options and customization. They can be fabricated into various profiles, such as standing seam, corrugated, or flat sheets, allowing architects and designers to achieve their desired aesthetic and functional outcomes. Additionally, aluminum panels can be easily formed, curved, or shaped to accommodate unique roof designs or architectural features, further enhancing their design flexibility.

Many aluminum panels for roofs incorporate reflective coatings or finishes that help reflect solar radiation. By reducing heat absorption, these coatings contribute to improved energy efficiency by minimizing heat transfer into the building. This, in turn, can reduce the cooling load on the HVAC system, leading to potential energy savings and enhanced thermal comfort inside the structure.

Aluminum is a highly recyclable material, and aluminum roof panels can be recycled at the end of their lifespan. Recycling aluminum uses substantially less energy than initial production, making it an environmentally benign option. By choosing aluminum panels for roofs, builders and homeowners contribute to the circular economy and reduce the demand for new raw materials.

Aluminum panels for roofs require minimal maintenance throughout their lifespan. Unlike some other roofing materials, aluminum does not require frequent painting, sealing, or coating to preserve its durability or appearance. Periodic cleaning with water and mild detergent is typically sufficient to keep the panels clean and free from debris, ensuring their optimal performance and aesthetic appeal.

These detailed features collectively make aluminum panels an attractive roofing solution, offering a balance of strength, durability, lightweight construction, design versatility, energy efficiency, recyclability, and low maintenance requirements.

Aluminum panels installation requires careful attention to detail and adherence to specific guidelines. Here are detailed instructions on how to install aluminum panels:

In conclusion, this essential guide has provided a comprehensive overview of aluminum panels, highlighting their numerous advantages and installation considerations. Aluminum panels offer a durable, versatile, and visually appealing solution for various applications, from roofing to cladding. Their lightweight nature, weather resistance, and sustainability make them an excellent choice for both residential and commercial projects. By following the installation tips and guidelines outlined in this guide, you can ensure a successful and seamless installation process. Embrace the potential of aluminum panels to enhance your building’s performance, aesthetics, and longevity. With this knowledge in hand, you’re well-equipped to embark on your aluminum panel journey with confidence.

EXPLORE MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com