Discover a detailed reference to debar steel and its numerous uses in the building sector. Discover the value of debar steel in reinforcing concrete constructions like buildings, bridges, and foundations. Learn about the several varieties of debar steel available, including mild steel, high-strength reinforcement steel, stainless steel, and epoxy-coated rebar. Learn how debar steel increases structural integrity, load-bearing capacity, and resists cracking and failure. Investigate its applications in slabs, columns, beams, retaining walls, and seismic systems. This educational guide will help you make informed decisions when incorporating debar steel into your construction projects.

“Debar steel” refers to steel bars, often known as reinforcing bars or rebars. Debar steel is used in reinforced concrete constructions to increase tensile strength, improve structural stability, and avoid cracks. These bars are normally composed of carbon steel and feature ribbed patterns on the surface to promote adherence to the concrete.

Carbon steel is the most prevalent type of debar steel, however other materials such as stainless steel and composite bars are also in use. Concrete and steel have similar thermal expansiveness, therefore they combine well to create a strong all-weather material.

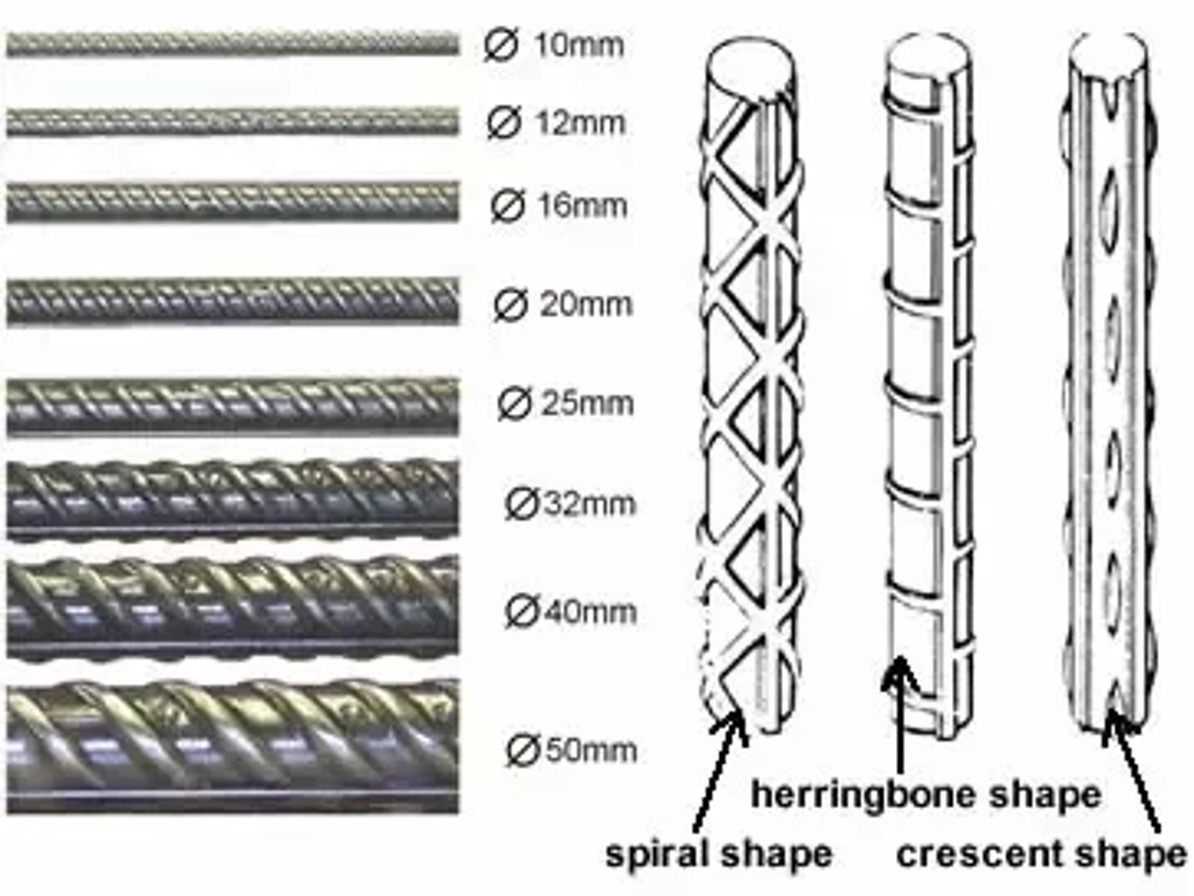

Rebar steel is available in a variety of diameters, grades, and shapes, including round, square, and deformed. The particular type and size of rebar steel used in a construction project are determined by the design requirements and structural engineer’s criteria.

The manufacturing process of debar steel (rebar steel) consists of numerous steps:

Steel billets are commonly made using two methods: continuous casting and electric arc furnace (EAF) melting. Continuous casting involves pouring molten steel into water-cooled molds, which harden into rectangular billets. EAF melting involves melting recycled steel scrap in an electric arc furnace to produce liquid steel, which is then cast into billets.

Steel billets are heated to the rolling temperature, which is normally between 1,200 and 1,300 degrees Celsius (2,192 to 2,372 degrees Fahrenheit). The heated billets are then fed through a series of rolling mills, which use pressure to shape and distort them into the correct profile. The rolling process may require numerous passes to reach the required size and shape.

Controlled deformation of steel billets occurs during the hot rolling process. This deformation is accomplished by utilizing specially constructed rolls having grooves or ribs on their surfaces. As the billets are rolled between these grooved rolls, distortion occurs, resulting in the characteristic deformations or ribs on the surface of the steel bars. These deformations strengthen the bond between the rebar and the surrounding concrete.

Following the hot rolling process, the deformed steel bars are rapidly cooled using a process called quenching. Quenching is the process of immersing bars in a water or oil bath to fast chill them. This rapid cooling helps to establish the steel’s desirable mechanical qualities, such as strength and hardness.

After quenching, the bars may go through tempering, which is a heat treatment technique. Tempering entails heating the bars to a certain temperature, usually between 400 and 700 degrees Celsius (752 to 1,292 degrees Fahrenheit), and then allowing them to cool gently. Tempering reduces the brittleness of steel bars, increasing their ductility and toughness.

After the deformed steel bars have cooled, they are cut to the necessary lengths with shearing machines or saws. The bars are frequently labeled with identification information such as the grade, size, and manufacturer’s emblem. Finally, the bars are bundled together using wires or straps for easy handling, shipping, and storage.

It’s vital to note that production procedures and standards can differ depending on regional and international specifications. Standards and regulations for deformed steel bars may vary by country and organization, such as ASTM (American Society for Testing and Materials) or BS (British Standards). These criteria ensure that deformed steel bars have the essential physical, mechanical, and chemical qualities for their intended use in construction.

Rebar steel, commonly known as reinforcing steel or deformed steel bars, has various unique properties that make it ideal for reinforcing concrete structures. Here are some of the primary features of rebar steel:

Rebar steel is distinguished by deformations or ribs on its surface. These deformations improve bonding with the surrounding concrete. The ribs increase the frictional resistance between the rebar and concrete, which improves load transfer and prevents slippage.

Rebar steel is designed to have a high tensile strength, allowing it to endure heavy pulling or stretching pressures. This strength contributes to the reinforcement of concrete elements, allowing them to endure tension and avoid cracking or failure.

Rebar steel has strong ductility, which means it can withstand large deformation before fracture. This characteristic allows it to accommodate slight movements or settlements in the concrete structure while maintaining structural integrity.

Rebar steel is easily welded using standard welding processes, such as electric arc welding. This enables the design of reinforced structures with complicated shapes and arrangements.

Protective coatings such as epoxy or zinc are frequently used to improve the corrosion resistance of rebar steel. These coatings operate as a barrier, preventing moisture and corrosive substances from reaching the steel surface and extending the life of the reinforcement.

Rebar steel comes in standardized sizes such as #3, #4, #5, #6, #7, #8, #9, #10, #11, #14, and #18. These measurements describe the diameter of the bars, allowing for simple specification and selection depending on structural design needs.

Rebar steel is highly compatible with concrete due to its similar coefficients of thermal expansion. This compatibility ensures that the rebar and concrete expand and contract at the same rate, reducing the likelihood of cracks or structural problems.

Rebar steel is highly recyclable, making it an environmentally friendly option. After the destruction of a reinforced concrete structure, the rebar steel can be recovered, recycled, and utilized to make new steel products, lowering the requirement for virgin steel manufacturing.

These traits combine to make rebar steel an important component in reinforcing concrete structures, providing strength, durability, and stability to the overall construction.

Rebar steel comes in a variety of varieties, each tailored to satisfy certain construction needs and applications. Some of the most prevalent varieties of rebar steel are:

Mild steel rebar, also known as Grade 250 rebar, is the most often used form of rebar. It has a low carbon content and is appropriate for general-purpose applications that do not require great strength.

Grade 500 rebar has a higher tensile strength than mild steel rebar. It is commonly utilized in constructions with great load-bearing capability, such as high-rise buildings, bridges, and large infrastructure projects.

Stainless Steel Rebar is produced from corrosion-resistant stainless steel alloys. It is generally utilized in situations that are prone to corrosion and rusting, such as coastal locations or chemically exposed structures.

Epoxy-coated rebar is a form of rebar with a protective epoxy coating on the surface. The coating functions as a corrosion barrier, extending the life of the rebar in harsh settings such as marine structures or chloride-rich locations.

Galvanized rebar is coated with zinc using a hot-dip galvanizing technique. The zinc coating resists corrosion, making it ideal for constructions exposed to moisture, such as parking garages or utility facilities.

It is a nonmetallic alternative to typical steel rebar. It is light, corrosion-resistant, and has a high tensile strength. CFRP rebar is widely employed in applications requiring weight reduction and corrosion resistance, such as rehabilitation projects or constructions with electromagnetic considerations.

These are only a few examples of the various varieties of rebar steel available. Design criteria, climatic circumstances, and project specifications all play a role in determining the best type of rebar to use. To guarantee that the appropriate type of rebar is utilized for a specific construction project, consult with structural experts and adhere to local building laws and standards.

Debar steel, also known as reinforcing steel or reinforcement bars, is widely used in the construction industry to improve the strength, durability, and structural integrity of concrete structures. Here are some common applications for rebar steel:

Rebar steel is commonly used to reinforce concrete structures such as buildings, bridges, dams, tunnels, retaining walls, and foundations. It adds tensile strength to concrete, reducing cracking, bending, and structural failure.

Rebar steel is frequently used in the construction of slabs and floors, such as suspended slabs, flat slabs, and reinforced concrete floors. It helps to distribute the load evenly and prevents cracking or sagging caused by large loads or temperature fluctuations.

Rebar steel is used to strengthen vertical columns and horizontal beams in structural systems. It boosts their load-bearing capability while also maintaining their stability and rigidity.

Rebar steel is used to build retaining walls that hold back dirt and prevent erosion. The rebar reinforces the wall, making it stronger and more stable under strain.

Deep structural parts driven into the earth to support enormous loads are made of rebar steel. The rebar reinforces the piles, helping them to withstand twisting and stabilizing the foundation.

Rebar steel is essential in earthquake-resistant buildings. It helps to absorb and dissipate seismic forces, improving the structural integrity and durability of buildings and infrastructure in earthquake-prone areas.

Road and pavement construction uses rebar steel to support concrete highways, airport runways, and parking lots. It helps to resist cracking and deterioration caused by strong traffic loads, as well as thermal expansion and contraction.

Rebar steel is commonly used in precast concrete elements such as beams, columns, and panels. It reinforces the casting process and guarantees that the end goods are strong and stable.

These are just a few applications for rebar steel in construction. The particular use of rebar steel is determined by design specifications, structural concerns, and local construction standards and regulations. To ensure effective use of rebar steel in construction projects, consult with structural engineers and adhere to industry norms.

To summarize, this comprehensive book has provided useful insights into the world of debar steel and its various applications in the building business. Debar steel is essential in reinforcing concrete constructions, assuring its strength, longevity, and resistance. Understanding the many varieties of debar steel available, such as mild steel, high-strength reinforcement steel, stainless steel, and epoxy-coated rebar, allows construction professionals to make informed judgments that efficiently satisfy project needs. From slabs and columns to retaining walls and seismic applications, debar steel demonstrates its importance in improving structural integrity and withstanding varied forces. Armed with this information, professionals may confidently use debar steel in their building projects, creating strong and long-lasting structures for the future.

EXPLORE MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com