| CATEGORY | VALUE |

| Grade | Aluminum alloy 6005, 6063, 6061… |

| Diameter | 89mm, 120mm, 127mm, 152mm, 178mm, 202mm… |

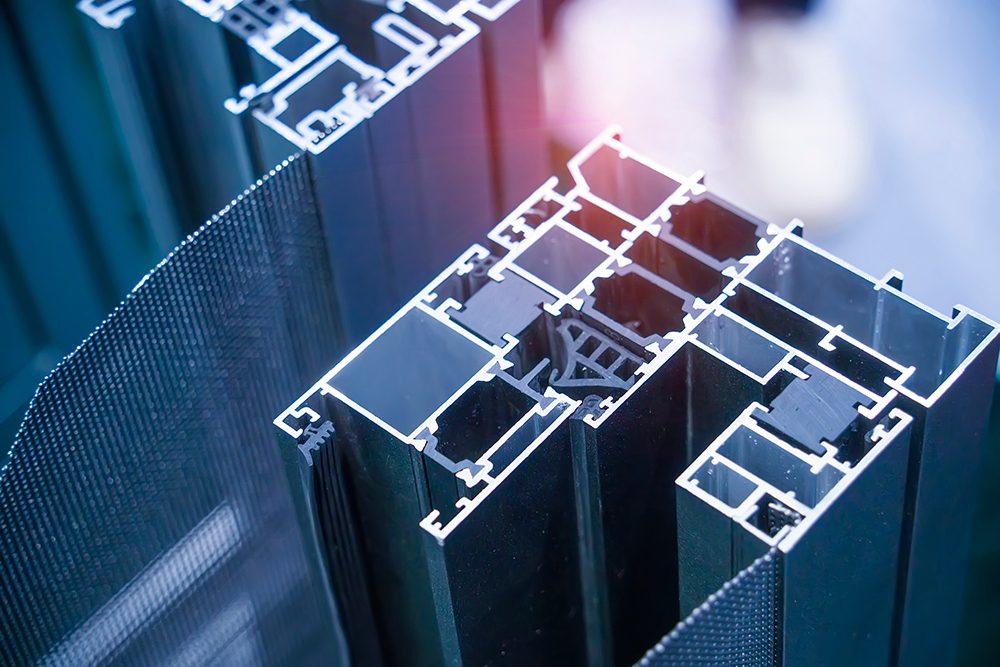

| Application | Used to produce aluminum profiles and extrusions for curtain walls, exterior glass facades, sunshades, supporting industries, and interior/exterior decoration, etc. |

| Standard | BS, ASTM, JIS… |

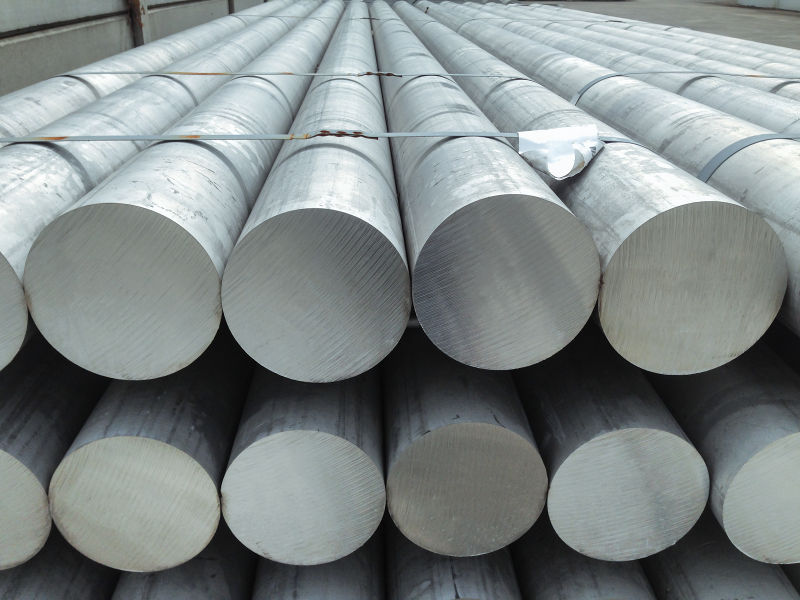

Aluminum Billet

Stavian Industrial Metal.,JSC provides aluminum billets of various types, serving the aluminum extrusion industry.

Our products are manufactured in large and reputable factories, meeting technical standards and are eligible for export.

Depending on customer requirements, billet products are cut to length or molded to many diameter sizes.

0 ₫

The rapid development of industries such as construction, transportation, electronics, energy, and others has generated a growing demand for aluminum billets. Aluminum billets are crucial input materials for the production of aluminum products, and this demand will continue to increase with the development of industries worldwide.

What Is Aluminum Billet?

Aluminum billet is a type of aluminum blank cast into a cylindrical or round bar shape through heat treatment and alloy mixing processes according to specific standards. Through the heat treatment process, the aluminum alloy 6063 gains resistance to general corrosion, including corrosion from cracks. This allows aluminum billets to be easily welded or bent using various methods, providing favorable conditions for processing and utilization in diverse applications.

Characteristics of Aluminum Billet

Aluminum billet is the result of heat treatment and pressure processes, resulting in outstanding mechanical properties such as high hardness, resistance to corrosion from external factors, and good elasticity, making it able to withstand strong impacts.

Aluminum billet is widely used for producing round components for machining, household appliances, and various applications. This helps optimize production time and save costs.

The high purity of aluminum billet is a result of strict production and processing procedures, ensuring the removal of impurities and unwanted alloys. Thanks to its purity, aluminum billet provides strength and increased durability while offering unique technical characteristics.

With a smooth surface, aluminum billet is suitable for processes such as electrostatic painting, aluminum anodizing, and many other applications.

Aluminum billet is available in various precise sizes, depending on customer requirements.

Additionally, aluminum billet is non-magnetic and non-toxic, providing safety for users and being environmentally friendly.

In Which Industries Is Aluminum Billet Applied?

Aluminum billet has many applications in various industries. Below are some examples of aluminum billet applications:

Construction Industry:

Due to its durability, corrosion resistance, and insulating properties, aluminum billet is an essential material in the construction industry. It is used to manufacture aluminum doors and windows, partitions, railings, aluminum steel structures, and other components in construction projects.

Transportation Industry:

Aluminum billet is used to manufacture components for the automotive, motorcycle, railway, and aviation industries. With its lightweight properties, aluminum billet helps reduce the overall weight of transportation vehicles, improve fuel efficiency, and enhance performance.

Energy Sector:

Aluminum billet is used in the manufacturing of components for the solar electronics and other renewable energy industries. Aluminum billet’s corrosion resistance and heat resistance qualities help protect electronic components in harsh environments.

Electronics Industry:

Aluminum billet is used to produce electronic components such as computer casings, heat sinks, heat pipes, and other parts. Aluminum billet’s good thermal conductivity and effective heat dissipation meet the requirements of high-end electronic applications.

Other Industries:

Aluminum billet is also used in various other industries such as LED lighting manufacturing, medical equipment, jewelry, and many other applications.

Aluminum billet is versatile and flexible in its applications, allowing it to be customized and manufactured into various aluminum products to serve the diverse needs of different industries.

Aluminum Billet Production Process

The aluminum billet production process at Alanmi is carried out following the following steps to ensure quality:

Step 1: Raw Material Inspection

The first step is to inspect the composition and quality of the raw materials. Each batch of Ingot raw material is tested for purity by taking random samples and conducting analysis. This is an important step before proceeding to the feeding, melting, and alloy mixing stages.

Step 2: Melting and Alloy Mixing

Ingot melting is done at a temperature of 660 degrees Celsius. This is the process of transforming Ingot from a solid state to a liquid state, altering the physical properties of pure aluminum. Subsequently, pure aluminum is mixed with various alloys according to standards to create aluminum alloys suitable for different production requirements.

Step 3: Billet Casting

In this stage, the aluminum billet product is aluminum alloy that has undergone heat treatment in the casting furnace to reduce the temperature and transition to a solid state. Aluminum is pulled out of the mold in specific sizes and diameters to form long bars. During this process, surface quality checks are crucial to ensure compliance with required standards.

Step 4: Cutting Billets into Finished Products

Depending on the specific requirements of the customer, aluminum billets will be cut into sizes suitable for their intended use. The standard length is usually 7,300mm, and after cutting both ends, it will be 6,500mm in length. For shorter length requirements, the cutting machine can be easily adjusted to create suitable and uniform finished product sizes before proceeding to the next stage.

Step 5: Homogenizing Aluminum Billets

After casting the billets into bars with the required sizes and diameters as per customer specifications, the billets will be transferred to the homogenizing stage. The product will be placed in a heat treatment furnace for a certain period to enhance its physical properties and finish. This is the final stage to create uniform and high-quality aluminum billet products in terms of quality and surface finish.

How Much Does Aluminum Billet 6063 Cost? Where to Buy Quality Aluminum Billet?

The price of Aluminum Billet 6063 depends on each supplier and the quality of the material. Stavian Industrial Metal Corporation is a leading supplier of Aluminum Billet with the best quality and price.

With a commitment to quality as the core value for its development, Stavian promises to provide customers with genuine products, meeting all quality standards, specifications, and varieties according to manufacturer standards. They adhere to quality measurement standards both in Vietnam and internationally.

Please contact us for detailed consultations and price quotes tailored to your specific needs.

Contact information:

Stavian Industrial Metal Joint Stock Company

Address: No.508 Truong Chinh Street, Nga Tu So Ward, Dong Da District, Hanoi City

Website: https://stavianmetal.com/

Hotline: +84 2471001868 / +84975271499

Email: info@stavianmetal.com

View more other products

Contact form