| CATEGORIES | DETAILS |

| Origin | Vietnam |

| Grain Size | < 45 micron: 12% max. > 150 micron: 10% max. |

| Chemical Composition | Al2O3 content: 98.5% up to 98.78% Impurities: specified upon request |

Alumina

Alumina, commonly known as aluminum oxide Al2O3, is extracted from bauxite ores in tropical and subtropical regions. It is used in the production of aluminum – a metal slated for significant growth in the advancement toward a low-carbon economy.

The alumina distributed by Stavian Industrial Metal.,JSC is extracted and refined using the Bayer process, meeting international standards.

0 ₫

From its heat resistance and abrasion resistance to its strong moisture absorption and catalytic properties, activated alumina offers flexibility and efficiency to manufacturing processes and industrial applications. Let’s explore the article below to gain a better understanding of activated alumina, its characteristics, and its applications.

What is Activated Alumina

Activated alumina is a type of material produced from aluminum hydroxide through a dehydroxylation process to create a porous structure material. With a large surface area that can exceed 200 m²/g, this material has many important applications in various industries.

One of the important applications of activated alumina is in moisture adsorption. With its ability to absorb water from the air, it is used to keep items dry. Additionally, activated alumina is also used as a filter to remove fluoride, arsenic, and selenium from drinking water, ensuring that the water is pure and safe.

Activated alumina is produced from aluminum oxide (alumina, Al2O3) and does not contain color-causing impurities. This makes it a material with special properties and wide-ranging applications in modern technology.

Properties of Activated Alumina

Activated alumina has the appearance of spherical, white particles. It is odorless and tasteless. Importantly, activated alumina is non-toxic and insoluble in water and alcohol.

Activated alumina has notable properties, including thermal and abrasion resistance with high mechanical strength. It also has a strong moisture adsorption capacity, also known as high water-holding capacity. Importantly, after the water adsorption process, activated alumina does not deform and does not affect the particle size (it does not swell or crack).

Activated alumina has a significant surface area exceeding 200 m²/g, allowing it to adsorb a large amount of substances from its surrounding environment.

Furthermore, activated alumina is used as a filter to remove fluoride, arsenic, and selenium from drinking water, or it can be applied in applications such as air drying systems and various industrial applications.

Applications of Activated Alumina

Widely used in industrial and laboratory applications:

In heatless air dryer systems, nitrogen generators, gas systems, and vacuum systems, activated alumina is used to create a continuous supply of dry air with a lower dew point of -70°C. This helps remove acids, transformer oils, lubricating oils, refrigerants, and acid-forming substances. Activated alumina removes corrosive acids, protecting valuable equipment from damage.

Diverse Applications in the Role of a Catalyst

In the supply of polyethylene and hydrogen peroxide, activated alumina is used for adsorption and catalysis of raw materials. It plays a crucial role in the production process.

It is also used as a chemical adsorbent material, including arsenic and fluoride, in processes such as the Claus stage Catalyst.

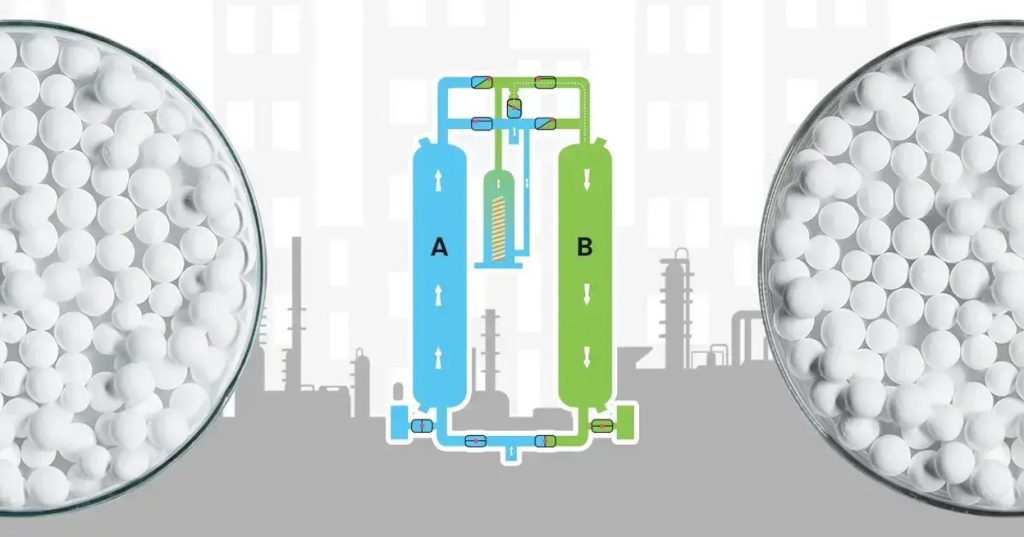

Application as a desiccant through adsorption process.

In this process, water in the actual air is trapped in the small pores of alumina as the air passes through them. Water molecules get trapped, making the air drier as it passes through the filter. This process can be reversed by heating the desiccant alumina to around ~200°C, at which point the water is released. This process is called regenerating the desiccant.

Fluoride Adsorption

Additionally, activated alumina is widely used for fluoride adsorption from drinking water.

Applications in Vacuum Systems

Applications in Vacuum Systems

Biological Material Applications

Furthermore, activated alumina is also used as a biological material. With its non-reactive properties in a biological environment and its mechanical properties, activated alumina is an ideal material for covering friction surfaces in artificial body parts such as prosthetics.

Storage Considerations for Activated Alumina

Activated alumina should be carefully packaged to protect it from dust, moisture, and physical damage. Use airtight and sturdy packaging to prevent exposure to the air.

To maintain the properties of activated alumina, it should be stored at the appropriate temperature. Typically, it should be stored at room temperature or in a cool warehouse to avoid the effects of high temperatures.

Activated alumina has a strong moisture-absorbing capacity. Therefore, it is necessary to avoid exposure to humid air. It should be stored in a dry environment or use sealed packaging to prevent moisture contact.

In addition, they can easily break or crack upon strong impact. Therefore, it is essential to ensure that transportation and storage are carried out carefully to avoid unintended physical impacts.

You should also periodically inspect the activated alumina to ensure its properties and performance. Check for any signs of cracks, deformation, or damage. If there are any issues, it should be replaced or stored properly.

Always adhere to the manufacturer’s instructions and regulations when storing activated alumina. This will ensure that it is stored correctly and maintains its best properties and performance.

Notes for Using Activated Alumina

When using activated alumina, please consider the following to ensure safety and effectiveness:

Read and follow instructions carefully:

Before using activated alumina, read and thoroughly understand the manufacturer’s instructions. Adhere to the guidelines regarding dosage, usage methods, and safety measures.

Using Personal Protective Equipment:

Ensure the use of personal protective equipment such as gloves, safety goggles, and masks when coming into contact with activated alumina. This helps protect the skin, eyes, and respiratory tract from direct contact and inhalation of dust or fumes from this substance.

Well-Ventilated Workspace:

Use activated alumina in an area with good ventilation systems to ensure proper air circulation and minimize the risk of inhaling dust or activated alumina fumes.

Transportation Precautions:

During transportation, make sure the packaging is secure and limit physical impact. Avoid collisions, drops, or contact with substances that may react.

Safe Waste Disposal:

When disposing of activated alumina, adhere to local regulations and procedures for chemical waste disposal. Do not discharge activated alumina waste into the environment.

We hope this article has provided you with useful information about activated alumina. If you are interested in or have a need for activated alumina or alumina pellets, please contact us for detailed advice and support:

Stavian Industrial Metal Joint Stock Company

Headquarters:

508 Truong Chinh Street, Nga Tu So Ward, Dong Da District, Hanoi, Vietnam

Hai Phong Branch:

6th Floor, Thanh Dat 1 Building, 3 Le Thanh Tong Street, May To Ward, Ngo Quyen District, Hai Phong City, Vietnam

Southern Branch:

12th Floor, Vincom Center Dong Khoi Building, 72 Le Thanh Ton Street, District 1, Ho Chi Minh City, Vietnam

Hotline: ‘+84 2471001868 / +84975271499

Website: https://stavianmetal.com/

Email: info@stavianmetal.com

View more other products

Contact form