| CATEGORIES | DETAILS |

| Coil | 3 – 16mm in thickness |

| Plate | 3 – 40mm in thickness and cut-to-order |

| Grade | SS400, Q345B, A36, Q235B, Q355B, A572, 1004… |

| Standard | JIS, ASTM, SAE, TIS, EN, MS, GB… |

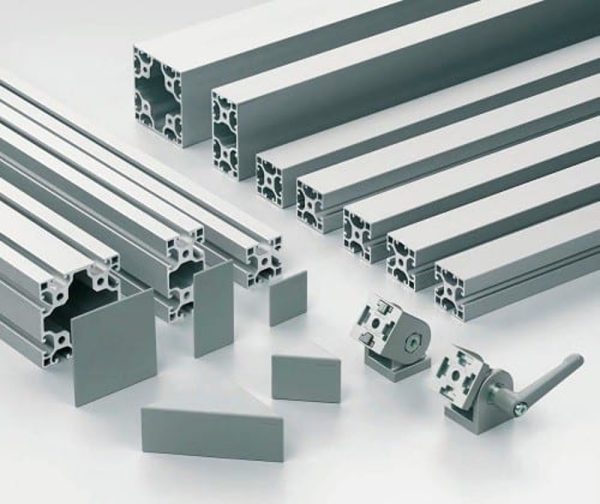

Hot Rolled Steel

Stavian Industrial Metal.,JSC provides a full range of hot rolled steel products in coils, plates, and a full range of common steel grades.

The products provided by Stavian Industrial Metal.,JSC are manufactured by prestigious global factories such as Hoa Phat, Formosa, TATA Steel, Nippon Steel, Hyundai Steel, Baotou, Shangchen Steel,…

0 ₫

What is hot-rolled steel

Hot-rolled steel is an important material widely used in the industrial sector. Its key characteristic is the high-temperature production process, which creates steel sheets with high hardness and flexibility. Hot-rolled steel has diverse applications and plays a crucial role in many industries.

Hot-rolled steel production process

Raw materials and alloy composition

Hot-rolled steel is primarily produced from raw materials like iron ore and carbon. The alloy composition can be adjusted to achieve desired mechanical and physical properties.

Hot-rolled steel manufacturing process

The hot-rolled steel manufacturing process involves iron smelting, steelmaking, hot rolling, and processing. This process ensures the quality and uniformity of hot-rolled steel.

- Iron Smelting: The process begins by melting the main raw materials, including iron ore and carbon, in a blast furnace. This process separates impurities from the raw materials and forms molten iron.

- Steelmaking: After iron smelting, the molten iron is transferred to a steelmaking furnace to adjust its chemical composition and remove remaining impurities. During this process, other alloying materials may be added to create hot-rolled steel with desired mechanical properties.

- Hot Rolling: Once the steelmaking process is complete, the molten steel is poured into holding furnaces to form initial steel slabs. These initial slabs are then transferred to hot rolling units, where they are rolled through rollers to create the final hot-rolled steel sheets. This process requires high pressure and high temperatures to modify the steel’s structure and achieve the desired hardness and flexibility.

- Post-Rolling Processing: After being rolled through the rollers, hot-rolled steel sheets may undergo further processing steps to achieve the final size and shape. Post-rolling processing steps may include cutting, bending, welding, and surface treatments.

- Heat Treatment and Surface Treatment: Finally, hot-rolled steel sheets may undergo heat treatment and surface treatments to improve their mechanical properties and appearance. These steps can include increasing hardness, enhancing elasticity, cleaning, plating, or painting.

The hot-rolled steel production process is closely controlled and regulated to ensure product quality and uniformity. Process parameters such as temperature, pressure, and rolling speed are adjusted to meet the technical requirements and quality standards of hot-rolled steel.

Processing and heat treatment steps in the production process

After production, hot-rolled steel can undergo various processing and heat treatment steps to create products with desired mechanical properties and shapes.

Classification of hot-rolled steel

- Common Hot-Rolled Steel (hot-rolled steel): Common hot-rolled steel is the standard type of hot-rolled steel widely used in many industries, including construction, automotive, machinery, and various other applications.

- Stainless Hot-Rolled Steel (hot-rolled stainless steel): Stainless hot-rolled steel has high corrosion resistance and is suitable for applications requiring sustainability in wet and chemical environments.

- Alloy Hot-Rolled Steel (hot-rolled alloy steel): Alloy hot-rolled steel combines hot-rolled steel with other alloying materials such as nickel, chromium, manganese, and molybdenum. This type of steel exhibits special mechanical and physical properties and is often used in applications that demand toughness and durability.

Uses of hot-rolled steel

- Construction Industry: Hot-rolled steel is widely used in the construction industry to manufacture structures, building frames, columns, pipes, and various other applications. Its hardness and flexibility make it an ideal material for construction projects.

- Automotive and Transportation Industry: Hot-rolled steel is employed in the production of automobiles, cars, trucks, and other transportation vehicles. Its mechanical properties and resistance to deformation meet the stringent requirements of this industry.

- Mechanical and Metalworking Industry: Hot-rolled steel is used in the manufacturing of mechanical parts, metalworking, machinery, and other technical components. Its durability and ease of processing make it an essential material in this industry.

Advantages and limitations of hot-rolled steel

| Advantages | Limitations |

| 1. Good Mechanical Properties and Deformation Resistance. | 1. Lower Corrosion Resistance Compared to Some Other Materials. |

| 2. Lower Cost Compared to Many Other Materials. | 2. Lower Strength and Hardness Compared to Some Types of Steel. |

| 3. Easy to Process and Available in Various Sizes. |

Hot-rolled steel prices

The prices of hot-rolled steel are influenced by various factors such as supply and demand, fluctuations in raw material prices, and economic conditions. International markets and trade policies can also impact the prices of hot-rolled steel.

For more detailed information on hot-rolled steel prices, please contact:

Email: info@stavianmetal.com

Hotline: 0975271499

Hot-rolled steel standards

Standards for hot-rolled steel are defined by various organizations and standardization associations worldwide. Below are some common standards for hot-rolled steel:

- ASTM A36/A36M: This is the standard set by the American Society for Testing and Materials (ASTM) for low-strength hot-rolled steel. It applies to hot-rolled steel plates used in construction and various general applications.

- ASTM A1011/A1011M: An ASTM standard for commonly used hot-rolled steel in industries and construction. It specifies requirements for the chemical composition, mechanical properties, and dimensions of hot-rolled steel plates.

- JIS G3101: This is a standard by the Japanese Industrial Standards (JIS) for common hot-rolled steel. It defines requirements for the chemical composition, mechanical properties, and dimensions of hot-rolled steel.

- GB/T 1591: A standard by the Chinese National Standards (GB) for high-strength alloy hot-rolled steel. It applies to high-strength alloy hot-rolled steel plates used in construction and other industries.

- EN 10025: A European standard (EN) for low-strength hot-rolled steel. It specifies requirements for the chemical composition, mechanical properties, and dimensions of hot-rolled steel plates.

Conclusion

Hot-rolled steel is an important and versatile material in the construction and metalworking industries. Through the production and processing processes, it provides reliable steel plates with good mechanical and physical properties. Hot-rolled steel is widely used in construction, the automotive industry, machinery, and many other industries. The hot-rolled steel industry continues to develop manufacturing and processing technologies, exploring new applications, and discovering potential developments in various industrial and environmental fields.

LEARN MORE

What is hot-rolled coil steel? Hot-rolled coil steel prices today

View more other products

Contact form