This comprehensive tutorial covers all you need to know about GL steel. Discover the features, applications, and advantages of Galvalume steel, which is a popular choice in a variety of industries. Learn about the corrosion resistance, durability, and formability of GL steel, which make it suitable for roofing, cladding, automotive components, and construction. Learn about the fabrication procedures used to convert GL steel coils and sheets into finished products. Whether you are an industry specialist or simply want to learn more about GL steel, this guide will give you vital insights into its properties and diverse applications. This comprehensive book will take you deep into the world of GL steel.

GL steel stands for “Galvalume steel.” It is a type of steel that has been coated with zinc and aluminum to improve its corrosion resistance. Galvalume steel is manufactured using a continuous hot-dip process in which the steel substrate is immersed in a molten bath of zinc and aluminum. This causes a protective layer of zinc-aluminum alloy to develop on the steel’s surface. The alloy coating provides two types of protection: aluminum for barrier protection and zinc for galvanic protection. Galvalume steel has good corrosion resistance, heat resistance, and formability, making it ideal for a variety of applications such as roofing, cladding, automobile production, and construction.

Galvalume (GL) steel has certain qualities that make it an attractive option for a variety of applications. Here are the main characteristics of galvalume steel:

Galvalume steel has good corrosion resistance. The alloy coating’s zinc and aluminum composition acts as a sacrificial barrier, protecting the underlying steel from rust and corrosion. This feature makes Galvalume steel ideal for use in severe and corrosive situations, such as coastal areas and industrial settings.

Galvalume steel is renowned for its outstanding durability. It provides long-lasting performance because of the protective coating, which keeps the steel from deteriorating over time. This resilience ensures that structures and components built of Galvalume steel can survive weather, mechanical stress, and other external forces, resulting in a longer useful life.

Galvalume steel has strong heat resistance.It can withstand high temperatures while maintaining structural integrity. This feature makes it excellent for applications involving heat or thermal cycling, such as roofing materials, industrial ovens, and HVAC systems.

Galvalume steel is extremely formable, meaning it can be easily curved, bent, and molded into a variety of shapes and designs. It keeps structural integrity during the forming process, making it adaptable to a variety of applications and allowing for the production of complicated shapes and structures.

Galvalume steel has an appealing appearance that mixes steel’s metallic shine with the smooth, silvery finish of the alloy coating. This aesthetic appeal makes it a popular choice for architectural applications, cladding, and other projects that require visual appeal.

Galvalume steel is lighter than other construction materials like concrete or solid steel. Its lightweight design makes it easier to handle, transport, and install, lowering construction time and costs.

Galvalume steel is readily recyclable, which adds to its sustainability and environmental friendliness. It can be recycled and reused without losing its qualities, lowering the demand for new raw materials and reducing waste.

Galvalume steel provides a cost-effective alternative for a variety of applications. Its longevity, corrosion resistance, and low maintenance needs lead to long-term cost savings. Furthermore, its lightweight design lowers transportation and installation costs.

These qualities combine to make Galvalume steel an extremely attractive material for a variety of applications, including roofing, cladding, automotive manufacture, construction, and the industrial sector. Its combination of corrosion resistance, durability, heat resistance, formability, and aesthetic appeal leads to its market success.

Galvalume (GL) steel manufacturing consists of multiple stages that transform raw materials into final products. Here’s a summary of the normal fabrication process:

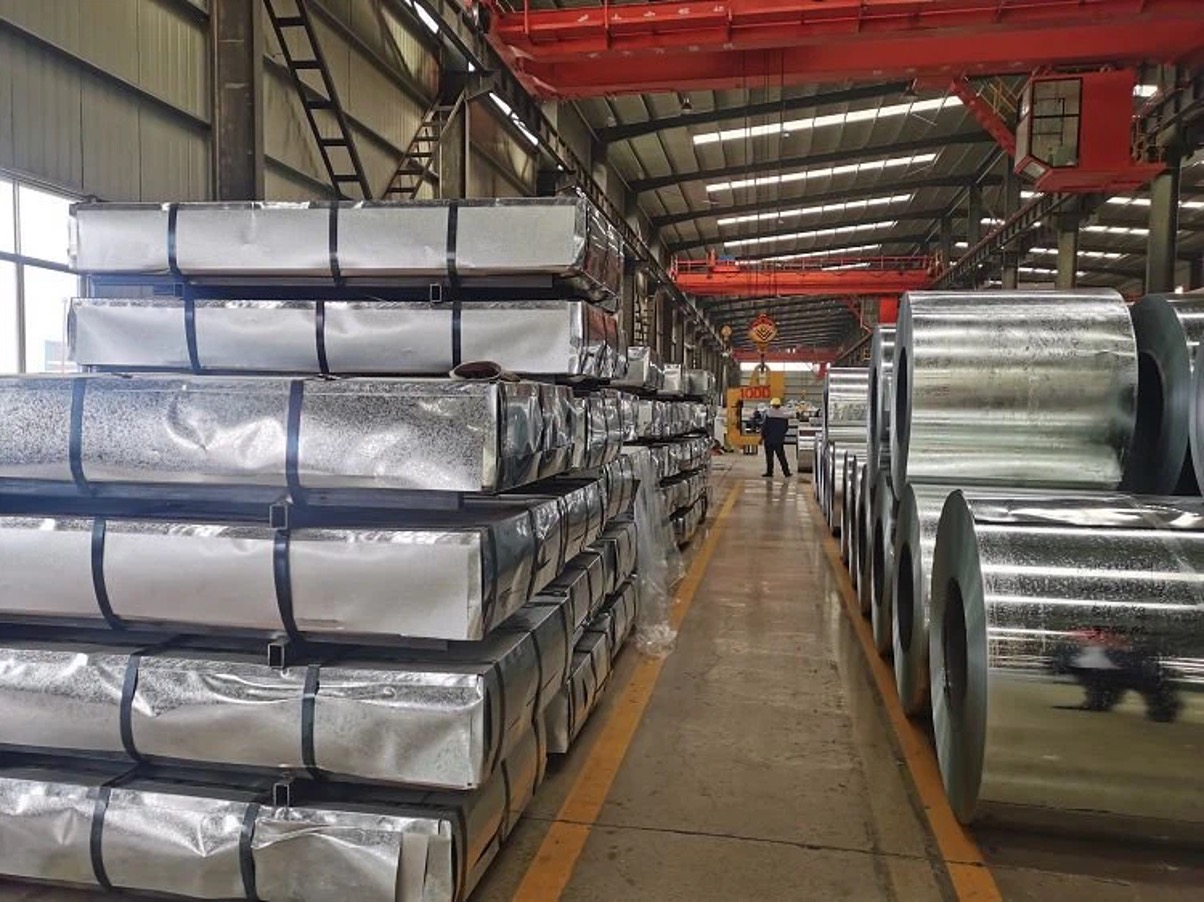

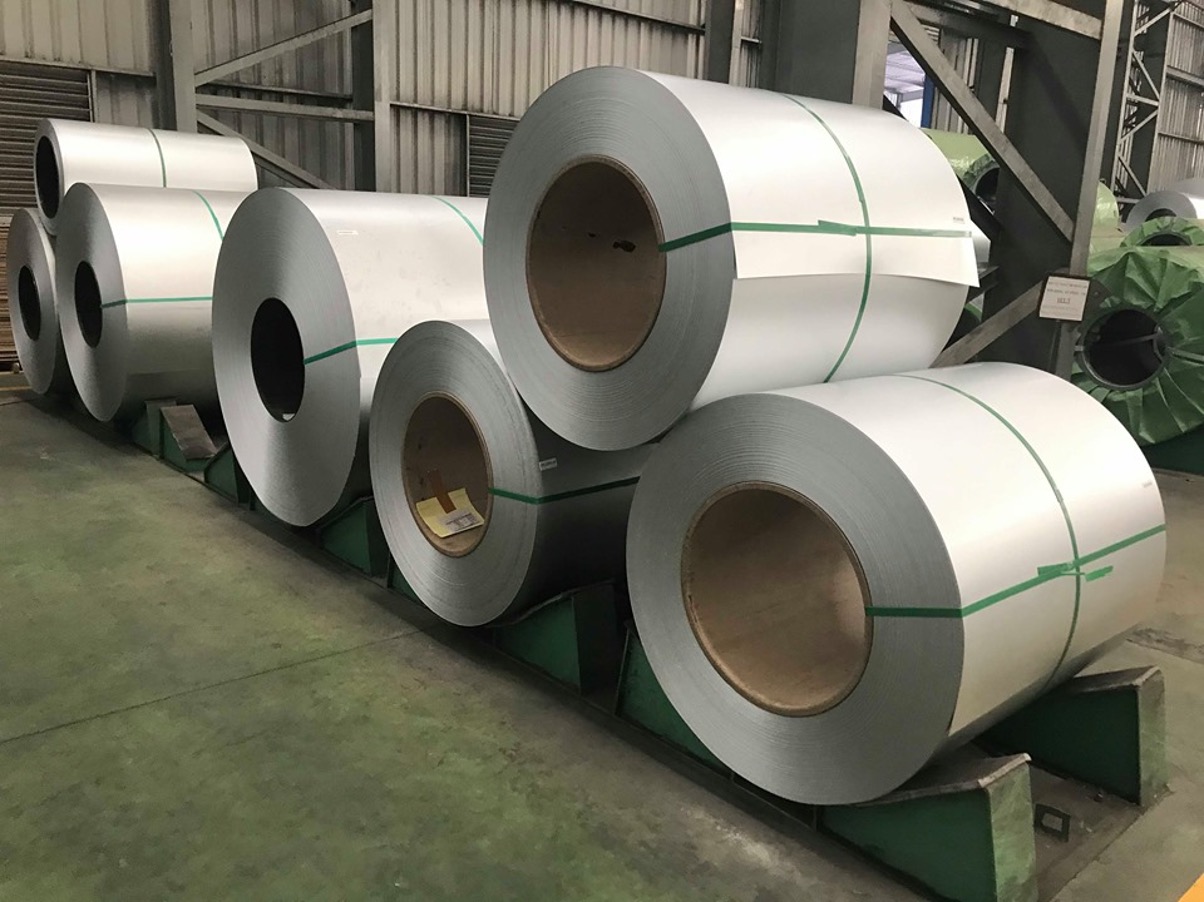

The procedure begins with preparing the GL steel coils. The coils are inspected for surface faults such as scratches or dents, and then cleaned to eliminate any impurities or oils.

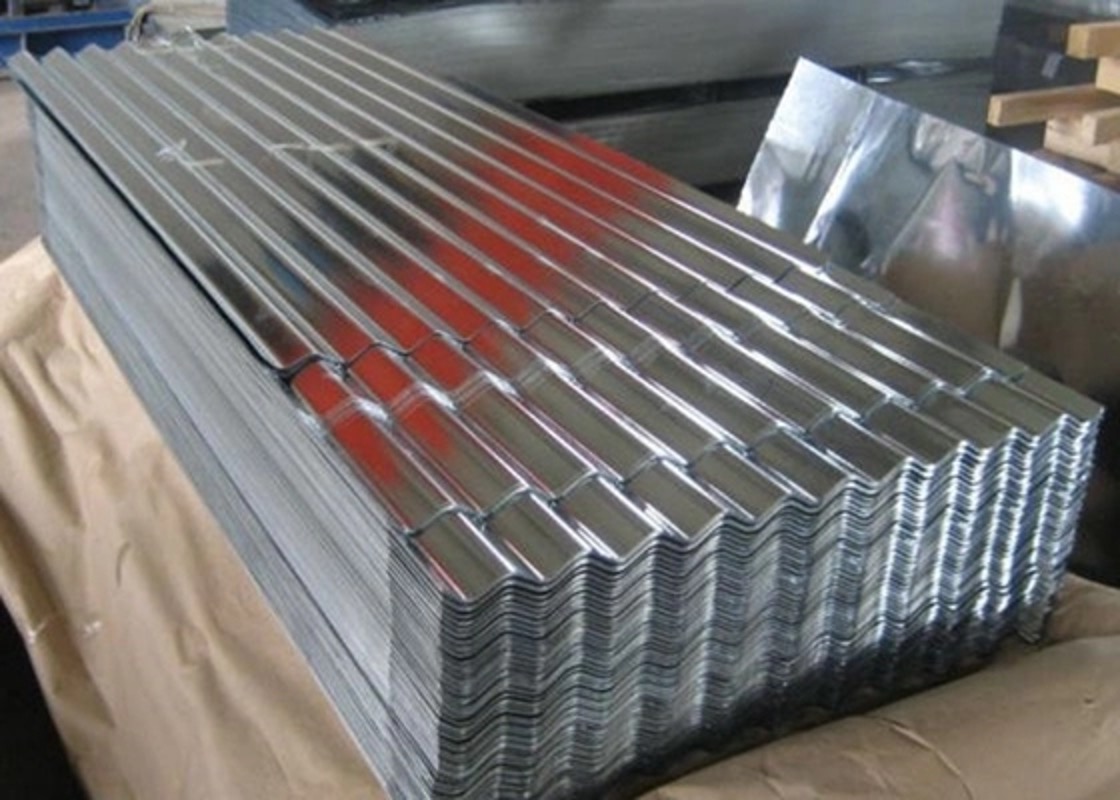

The GL steel coils are then cut to the necessary dimensions or lengths using a variety of methods, including shearing, slitting, and laser cutting. This procedure guarantees that the coils are reduced to reasonable sizes for subsequent processing.

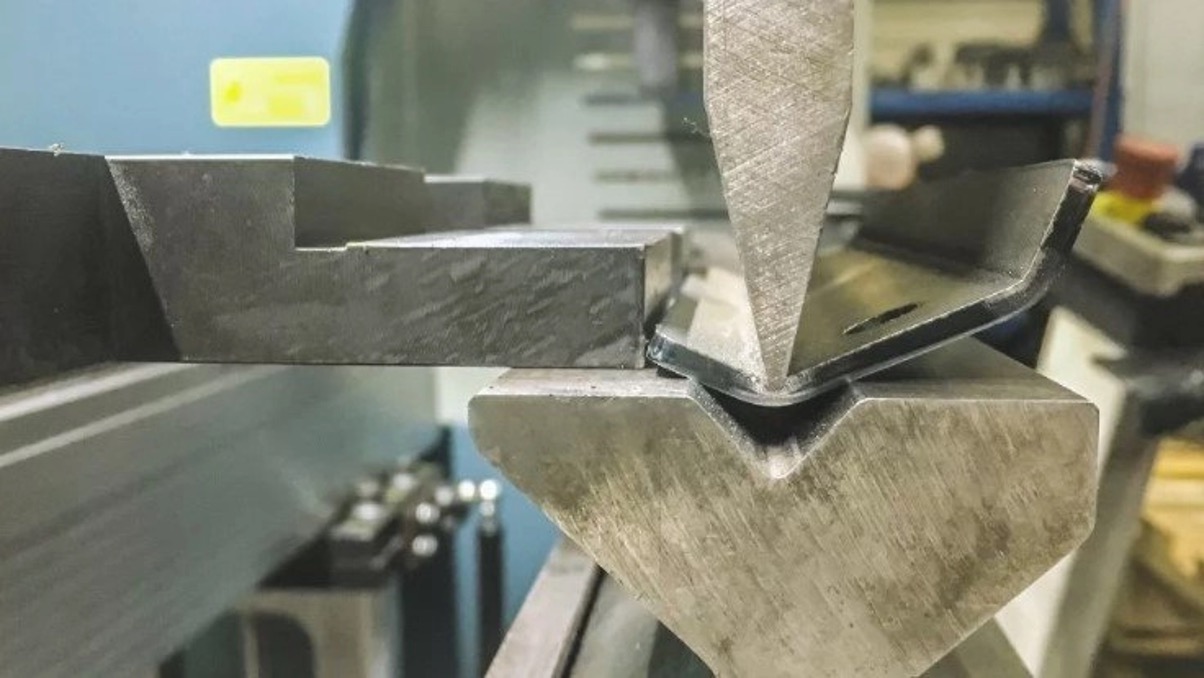

GL steel sheets or strips are fed through a variety of forming and bending machinery to shape them into the necessary profiles or components. Depending on the project’s specifications, this may entail techniques such as roll forming, press braking, or stamping.

If necessary, GL steel components may be connected or welded together to form bigger structures or assemblies. Arc welding, spot welding, or laser welding can be used to securely combine the GL steel parts.

The GL steel components may be surface treated once they have been fabricated. This can include operations like painting, powder coating, or galvanizing to improve aesthetics or give increased corrosion resistance.

Quality control methods are applied throughout the fabrication process to guarantee that the GL steel components fulfill the necessary requirements and standards. This may include dimensional checks, visual inspections, mechanical testing, and other quality assurance methods.

Once the fabrication is complete and the GL steel components have passed quality inspection, they are subjected to any last finishing touches, such as deburring or polishing. The finished components are properly wrapped and ready for transport or installation.

It is vital to note that the fabrication process will vary depending on the intended application, design complexity, and fabrication facility capabilities. Advanced procedures and machinery are frequently used to assure precision, efficiency, and high-quality final products.

GL steel, in various forms such as GL steel coils, GL steel sheets, and GL steel panels, is used in a wide variety of industries. Here are some frequent applications for the various GL steel types:

Roofing and Cladding: GL steel coils are widely utilized in roofing and cladding applications on residential, commercial, and industrial buildings. The corrosion resistance, durability, and formability of GL steel make it an excellent choice for safeguarding structures from the elements while also giving aesthetic appeal.

Automotive Industry: The automotive industry uses GL steel coils to manufacture body panels, structural components, and other elements. The corrosion resistance, formability, and strength of GL steel help to produce lightweight but durable vehicle components.

Construction: GL steel coils are commonly utilized in building applications such as structural elements, roofing systems, wall panels, and framing. GL steel’s strength, durability, and corrosion resistance make it ideal for withstanding severe loads and structural stresses.

Appliances and HVAC: GL steel coils are used in the manufacture of refrigerators, washing machines, ovens, and HVAC systems. GL steel’s corrosion resistance, heat resistance, and formability make it an ideal material for appliance exteriors.

Industrial Applications: GL steel coils are used in a variety of industrial applications, including storage tanks, ductwork, roofing, and agricultural buildings. GL steel’s corrosion resistance and durability make it ideal for use in hostile locations, chemical exposure, and extreme weather conditions.

Architectural Applications: GL steel sheets and panels are employed in architecture because of their aesthetic appeal, durability, and resistance to corrosion. They are suitable for exterior cladding, wall panels, decorative features, and roofing in both residential and commercial buildings.

Solar Energy Systems: GL steel sheets and panels are used to manufacture mounting systems and frames for solar panels. GL steel’s corrosion resistance and strength make it an excellent material for withstanding outdoor conditions and serving as a sturdy foundation for solar arrays.

Agricultural Buildings: GL steel sheets and panels are widely used in agricultural structures such as barns, sheds, and storage facilities. Their corrosion resistance, durability, and ease of installation make them ideal for agricultural use.

Industrial Equipment and Enclosures: GL steel sheets and panels are used to make industrial equipment, cabinets, and containers. GL steel’s corrosion resistance and durability make it ideal for preserving equipment and assuring lifetime in industrial environments.

These applications highlight GL steel’s versatility and widespread use in a variety of industries, where features such as corrosion resistance, durability, formability, and aesthetic appeal are highly prized. The precise form of GL steel, whether in coil, sheet, or panel form, can be customized to fulfill the specific needs of various applications.

To summarize, this thorough guide has supplied a plethora of information on GL steel, commonly known as Galvalume steel. We investigated its features, applications, and advantages, providing light on why it is widely employed in a variety of industries. From its superior corrosion resistance and durability to its formability and aesthetic appeal, GL steel has proven to be a versatile and dependable material. GL steel, available in coils or sheets, is used in roofing, cladding, automobile production, construction, and other applications. Armed with this knowledge, you can now make informed decisions and recognize the value that GL steel adds to various projects.

EXPLORE MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com