This useful article discusses the features, dimensions, as well as the advantages of H-beam steel. Learn about H-beam steel‘s outstanding load-bearing capability and structural stability, which makes it a popular choice for building projects. Explore its adaptable dimensions, which allow for creative design and personalization. Discover the benefits of employing H-beam steel, such as its affordability, durability, and versatility. Understanding the qualities, proportions, and benefits of H-beam steel is critical for designing strong and robust structures, whether you’re an engineer, architect, or builder. Take advantage of the benefits of H-beam steel for your construction needs.

H-beam steel, also known as wide-flange beam, is a form of structural steel beam with a “H”-shaped cross-section. It is widely used in building and engineering due to its excellent load-bearing capacity and structural stability.

Steel H-beam is primarily constructed of carbon or low-alloy steel and is welded or hot rolled. The production method entails heating a steel billet or ingot before shaping it into the necessary H-shaped cross-section. The resulting beam is made up of two horizontal flanges joined by a vertical web.

Steel H-beam comes in a variety of sizes and dimensions, allowing for versatility in design and construction. H-beam steel’s parameters, such as beam height, flange width, and web thickness, indicate its specific size and weight.

H-beam steel is available in a wide range of sizes and dimensions, allowing for flexibility in design and construction. The specific sizes and dimensions of H-beam steel can vary depending on regional standards and manufacturer specifications. However, here are some common H-beam steel sizes and dimensions:

Height (H): The height of an H-beam steel refers to the vertical distance between the top and bottom flanges. Millimeters (mm) or inches (in) are commonly used measurement units.

Flange Width (B): The flange width of an H-beam steel refers to the horizontal width of each flange. Millimeters (mm) or inches (in) are commonly used measurement units..

Web Thickness (t1): The web thickness of an H-beam steel refers to the thickness of the vertical web connecting the two flanges. Millimeters (mm) or inches (in) are commonly used measurement units.

Flange Thickness (t2): The flange thickness of an H-beam steel refers to the thickness of each flange. Millimeters (mm) or inches (in) are commonly used measurement units.

For example, a common H-beam steel size might be denoted as “H-beam 200x200x8x12,” where:

Height (H) = 200 mm

Flange Width (B) = 200 mm

Web Thickness (t1) = 8 mm

Flange Thickness (t2) = 12 mm

This indicates that the H-beam has a height and flange width of 200 mm, a web thickness of 8 mm, and a flange thickness of 12 mm.

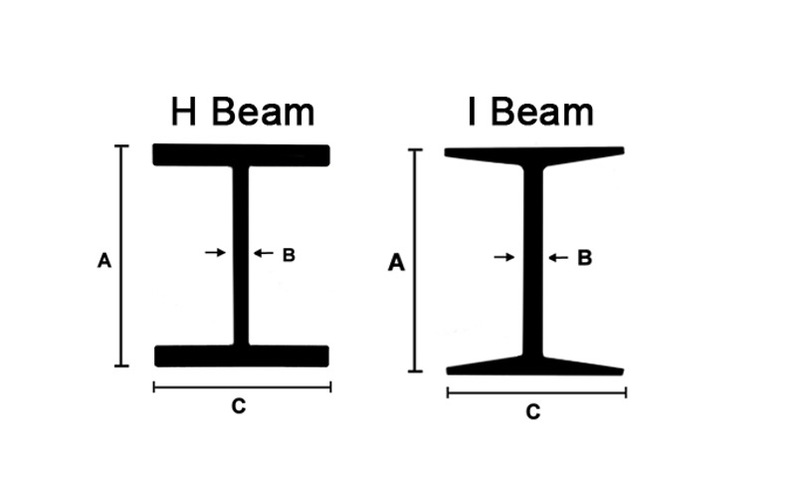

The term “H-beam wide flange” refers to the special design of flanges in an H-beam steel. The flanges are wider than the web, creating a large cross-section. The broad flanges improve load-bearing capacity and structural stability, making wide-flange H-beams ideal for applications that require strong support for heavy loads.

For precise H-beam steel diameters, dimensions, and broad flange design alternatives, reference regional norms and manufacturer specifications, as they may differ depending on area and special requirements.

H-beam steel has various distinguishing characteristics that make it a popular choice for building and engineering tasks. Here are a few of its distinctive characteristics:

H-beam steel is known for its high load-bearing capacity. Its wide flanges and vertical web construction allow it to bear strong vertical and horizontal stresses, making it ideal for supporting huge structures and carrying significant weight.

The wide flanges of H-beam steel provide increased resistance to bending and twisting stresses. This structural stability protects the entire structure’s integrity, particularly in applications requiring strong support and resistance to deformation.

H-beam steel is versatile in construction because of its numerous sizes and dimensions. It can be tailored to unique project requirements, enabling engineers and architects to design and build structures of various sizes and configurations.

The H-shaped cross section of H-beam steel allows for efficient weight distribution along its length. This reduces concentrated stress spots and guarantees a more uniform distribution of forces, improving overall structural integrity and load-bearing capability.

H-beam steel is frequently seen as a cost-effective choice for construction projects. It has a high strength-to-weight ratio, reducing the quantity of steel required while retaining structural integrity. This could result in cost savings on material and transportation charges.

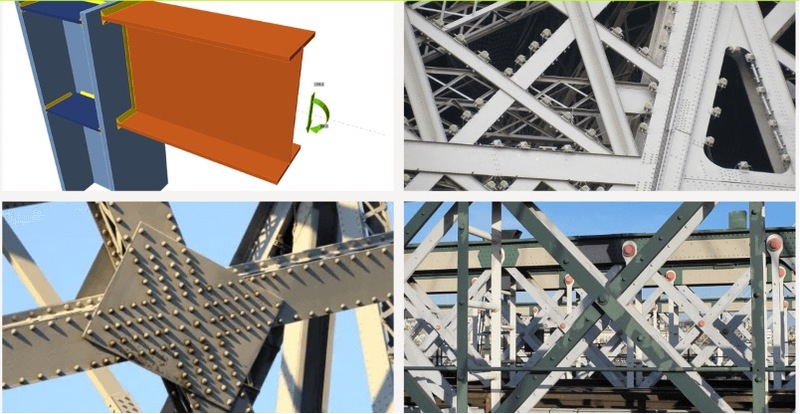

H-beam steel is used in a variety of construction projects, including buildings, bridges, industrial structures and infrastructure development. It is widely utilized in load-bearing constructions such as columns, beams, trusses, and frames, where strength and stability are critical.

H-beam steel is easily welded, allowing for efficient connections between beams and other structural components. This enables effective integration into complicated construction systems while also giving flexibility in design and construction processes.

H-beam steel is noted for its resilience and long-lasting properties. It is resistant to corrosion, distortion, and structural fatigue, guaranteeing that constructions made with H-beam steel keep their integrity over time.

These distinguishing characteristics make H-beam steel a dependable and commonly used material in the construction sector, enhancing the strength, stability, and longevity of diverse constructions.

H-beams and I-beams are two types of structural steel beams with different cross-sectional forms. While they share applications and load-bearing capacities, there are some significant differences between H-beams and I-beams:

It’s vital to remember that whether to use H-beams or I-beams is determined by elements including specific load requirements, span lengths, structural design, and project criteria. Consulting with structural engineers and adhering to local building laws and standards is critical in determining the best beam type for a given construction project.

The price of H-beam varies depending on a number of factors, including regional market conditions, supply and demand dynamics, steel grade, size, and quality. It is crucial to remember that steel prices fluctuate over time, and the information below provides a basic summary based on previous trends. To get the most up-to-date pricing information, always consult local vendors or market sources.

As mentioned before, I-beam steel is slightly less expensive than H-beam steel. This is primarily because I-beams use less steel material due to their thinner flanges, resulting in lower production and material costs. Furthermore, I-beams are more commonly manufactured and accessible in a variety of diameters, which contributes to their competitive pricing.

On the other hand, H-beam steel, with its larger flanges, has a higher load-bearing capability and may be slightly more expensive than I-beam steel. The additional material required to manufacture H-beams, together with their structural advantages, can result in a higher price point.

It is crucial to note that geographical variances and market conditions can have a considerable impact on the price differential between H-beam and I-beam steel. Local considerations such as transportation costs, import duties, and raw material availability can all have an impact on price discrepancies.

To accurately evaluate the price difference between H-beam and I-beam steel, seek quotations from numerous vendors or speak with local steel wholesalers for precise pricing information based on required sizes, requirements, and market conditions.

To summarize, H-beam steel is an excellent choice for construction projects due to its exceptional characteristics, size, and multiple benefits. H-beam steel‘s high load-bearing capacity and structural stability make it a dependable option for supporting huge loads. Its varied dimensions enable flexible design and customization, catering to a wide range of project requirements. The benefits of H-beam steel go beyond its strength, including cost-effectiveness, durability, and a wide range of applications. Whether it’s for bridges, industrial structures, or commercial buildings, H-beam steel delivers strong and resilient constructions. Accepting the qualities, proportions, and benefits of H-beam steel opens the way to more efficient and effective construction projects.

EXPLORE MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com