| Categories | Details |

| Origin | Southeast Asia Region |

| Size | Fine size: 0.15 – 6.3mm Lump size: 6.3 – 40.0mm |

| Chemical Composition | Fe: 60.0 – 68.0% SiO2 ≤ 4.5% Al2O3 ≤ 2.5% P ≤ 0.15% S ≤ 0.07% Moisture < 4.0% Microelement: specified upon request |

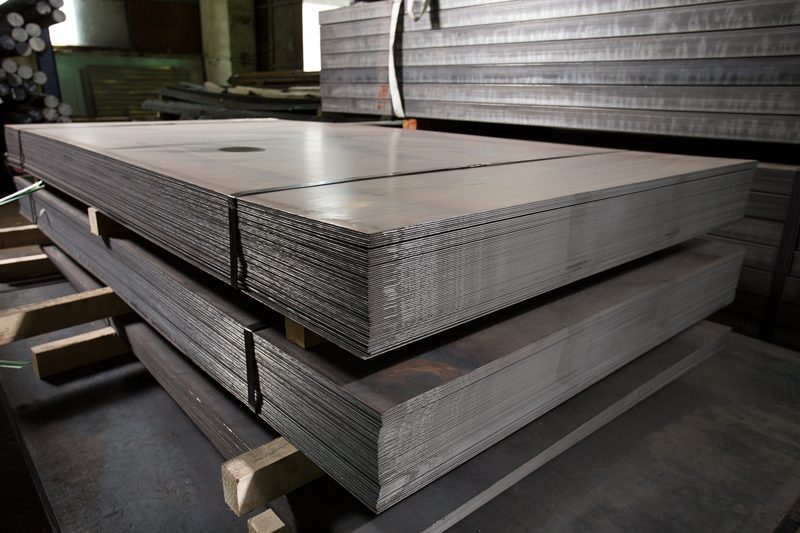

Iron Ore

Iron ore distributed by Stavian Industrial Metal.,JSC is carefully tested and certified by SGS. We also provide transparent origins for our products.

In addition to quality commitment, our company is also committed to abundant reserves, output and infrastructure to ensure uninterrupted trading activities.

0 ₫

Iron ore is the primary raw material for producing steel in our daily lives. So, what is iron ore used for? What are the types of iron ore compounds being exploited? And the impact of these compounds on the global economy will be revealed in today’s article. Let’s explore with Stavian!

Detailed information about iron ore in Vietnam

Iron ore is a precious resource that plays a crucial role in many aspects of life and economic development. Here are the most important pieces of information about this raw material:

What is iron ore?

Iron ore is a type of compound containing metals or precious minerals. It is one of the most important mineral resources in the world as it is mined to serve many industries, playing a significant role in shaping the global economy.

With a high iron content, approximately 95-98% of the mined iron ore is used to produce iron and steel, two essential materials for many industries.

Composition of iron ore

To understand what iron ore is, let’s delve into its main components that make up this type of rock. This compound is not just an ordinary rock but a treasure hidden behind its dark gray, bright yellow, or reddish-brown appearance.

Common types of iron ore include magnetite (Fe3O4, 72.4% Fe), hematite (Fe2O3, 69.9% Fe), goethite (FeOOH, 62.9% Fe), limonite (FeO(OH)•n(H2O), 55% Fe), and siderite (FeCO3, 48.2% Fe).

Some types of ore contain very high iron content, especially hematite and magnetite (over 60% iron). These ores, known as “natural ores” or “direct shipping ore” (DSO), have sizes larger than 6mm.

In terms of properties, these iron ores can be directly fed into blast furnaces for steel production. Many consider these compounds not only as common raw materials but also believe that, in the global raw material world, only iron ore and crude oil can be compared because of their significant impact on life.

Domestic import-export situation and iron ore prices

Government regulations have decided to loosen restrictions on iron ore exports. This has led many regions, like a flood, to race for export permits for their businesses. The amount of these compounds exported has reached millions of tons, with some businesses exceeding the permitted limit, almost to the point of illegal exports.

Meanwhile, domestic blast furnace plants are facing a temporary shutdown due to a lack of iron ore for production. The export of these raw materials has directly impacted domestic steel production and is expected to cause significant financial damage to the national budget.

Many large manufacturing companies in Vietnam, such as Hoa Phat, are shifting to the use of magnetite ore with an iron content of over 63% Fe. If they have to import ore from foreign markets, the price of Vietnamese iron ore will be around 2.4 million VND per ton.

However, the domestic purchase price for this compound is only between 2-2.3 million VND per ton. For limonite ore with lower iron content, only from 50% Fe and below, the price is even lower, at around over 1 million VND per ton.

To process this type of ore in blast furnaces, companies need to incur additional costs for the initial processing stage. If allowed to export ore, the actual cost that Vietnamese companies would receive is only from 1.3 to 1.4 million VND per ton for ore with an iron content above 63% Fe. Therefore, many ore-producing companies are choosing to sell domestically to avoid unnecessary risks and achieve higher profit margins.

Basic methods of identifying natural iron ore

Identifying iron ore is the process of determining whether a soil or rock sample contains enough iron to become a source of iron supply for the economy. Here are some ways to identify natural iron ore:

- Color: This type of ore is usually gray to black, or it can be shades of red or brown due to iron oxide. Darker and more uniform colors often indicate better quality.

- Hardness: Iron ore is typically very hard and resistant to manual destruction. If you cannot easily break or scratch the ore, it may be iron ore.

- Magnetic Properties: Iron is a strong magnetic substance. Use a magnet to see if it adheres to the soil sample. If the magnet sticks tightly, you may have found what you’re looking for.

- Chemical Testing: This method involves using chemicals to test the composition of the soil sample. This is usually done by scientists and geological experts.

- Structure: Iron ore often appears as particles or layers in soil or rock formations. This structure often indicates the organization and distribution of iron in the sample.

- Staining: When in doubt about whether a soil sample contains iron, you can try staining a small amount on filter paper. If it is indeed iron-containing compound, the liquid drop will appear similar to blood on the filter paper.

- Density: Iron-bearing minerals typically have a higher density than normal soil.

Identifying this compound is a professional task that requires in-depth knowledge of geology, mineralogy, and chemistry. These methods are often used by geological engineers to relatively identify the components of iron ore. However, accurate determination still requires detailed testing using professional means.

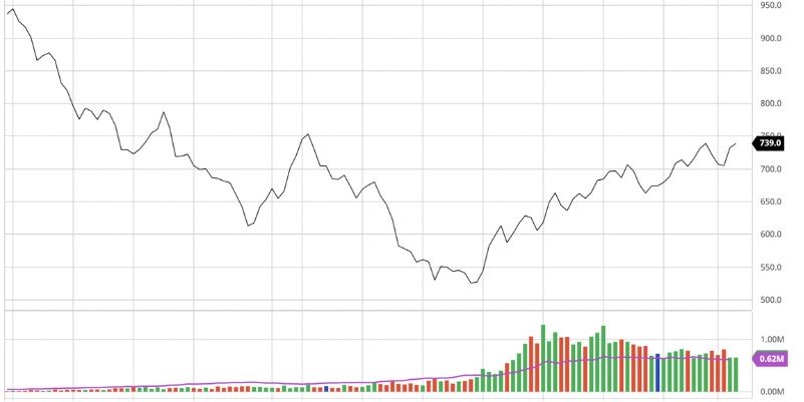

Factors influencing iron ore prices in and outside

The price of iron ore in Vietnam is deeply influenced by a range of macro and micro factors, creating a multi-dimensional picture of fluctuations in the domestic market. Here are important factors affecting the price change of this ore in the country:

Domestic demand and steel production activities

The demand for iron ore in the construction and steel production industry in Vietnam imposes requirements for stable supply and reasonable prices. Simultaneous fluctuations in domestic demand and steel production activities will simultaneously change the prices in the market. When demand is high, the price of this mineral will increase accordingly, and vice versa when demand decreases, the price will decrease to maintain balance in the market.

Extraction capacity and technology

The extraction capacity and new technologies can influence supply and prices. Efficiency in extraction, including the use of advanced methods and equipment, can help reduce production costs and keep the price of this iron-containing compound stable or decrease it.

The fluctuations of these factors pose challenges to many experts and market managers in Vietnam, requiring continuous observation to ensure stability and provide accurate forecasts in the Vietnamese ore market.

Tax policies and financial support from the government

Import tax policies and financial support measures from the government can alter the price of iron ore. High import taxes increase the cost of imports, potentially leading to price hikes in the domestic market. Conversely, support policies such as tax reductions or low-interest funding can decrease the price of iron ore.

Global price fluctuations and raw materials

The price changes of this iron-containing compound in the global market and related materials such as oil can cause fluctuations in the price of iron ore domestically. If global prices rise, prices in the Vietnamese market may also increase to maintain profitability for producers.

Environmental and occupational safety policies

Environmental and occupational safety policies set requirements and costs for the extraction of raw materials. These costs are often transferred to the price of iron ore, impacting the final price for consumers. Additionally, environmental protection measures such as emission fees can also increase the price of these raw materials.

Which unit offers reliable iron ore in the Vietnamese market

In the rapidly developing industrial market of Vietnam, there are numerous units engaged in the purchase or distribution of iron ore. So, how to choose a reputable unit? That unit is Stavian – a trusted brand in the metal industry today.

With over 10 years of experience in metal distribution, Stavian takes pride in offering the best services at extremely friendly prices. Furthermore, we provide highly attractive policies, ensuring transparency and reliability.

Conclusion

In this article, we’ve explored detailed information about the concept of iron ore and its uses. Market dynamics in Vietnam and globally can influence the price of iron ore. Enhancing knowledge and understanding of these factors will provide a clearer insight into the iron ore market in the global economy.

View more other products

Contact form