With the continuous advancements in construction technology and the increasing demand for improved thermal insulation and energy efficiency, foam insulated metal panels have become one of the top choices for current building projects. Featuring a lightweight design, ease of transport and installation, and impressive sound and thermal insulation properties, this material not only meets industrial needs but is also widely used in residential construction. Let’s explore with Stavian Industrial Metal the features, applications, and pricing of foam insulated panels for a comprehensive understanding of this product.

With its lightweight design, ease of transport and installation, and outstanding sound and thermal insulation capabilities, foam insulated metal panels are widely used in residential construction

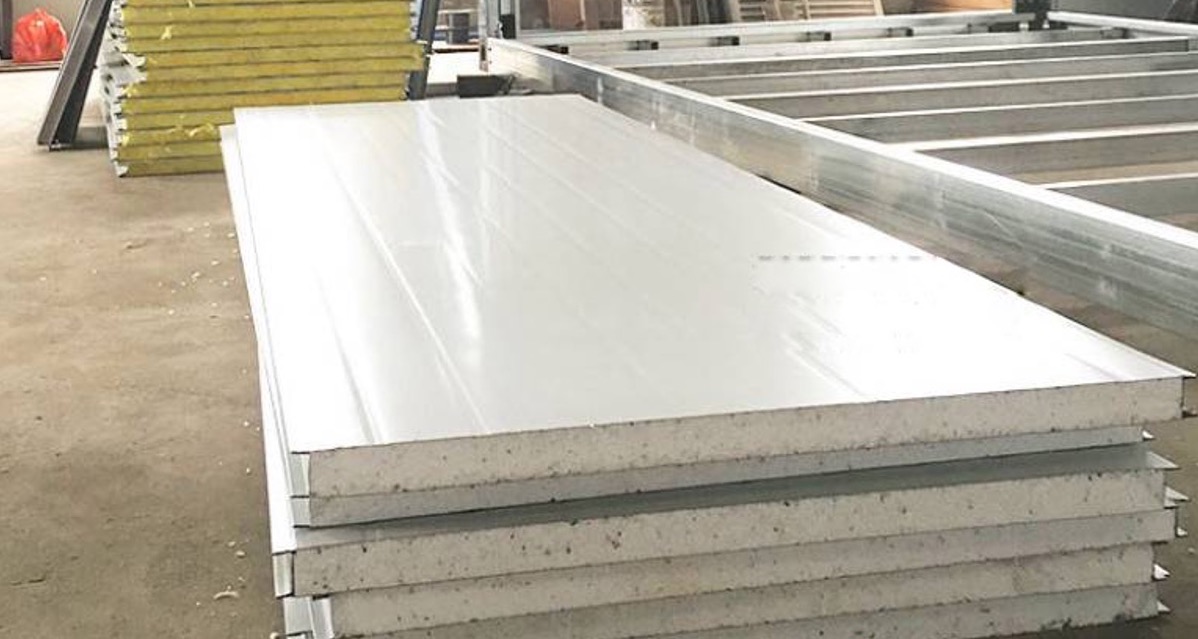

Foam insulated panels, also known as thermal insulation panels, are a common construction material used in a variety of applications today. These panels typically have a structure consisting of two outer layers of high-quality steel coated with electrostatic paint and a foam core in the middle. The foam core can be made of materials like EPS (Expanded Polystyrene), PU (Polyurethane), or fiberglass. The key features of fire resistance, soundproofing, and thermal insulation make foam insulated panels an efficient solution for enhancing the insulation and soundproofing of many building projects.

Foam insulated metal panels usually consist of two outer layers of high-quality steel coated with electrostatic paint and a foam core in the middle

Currently, there is a wide variety of thermal insulation foam panels on the market, each with distinct structures, panel sizes, and characteristics. Here are some common types of foam insulated panels available:

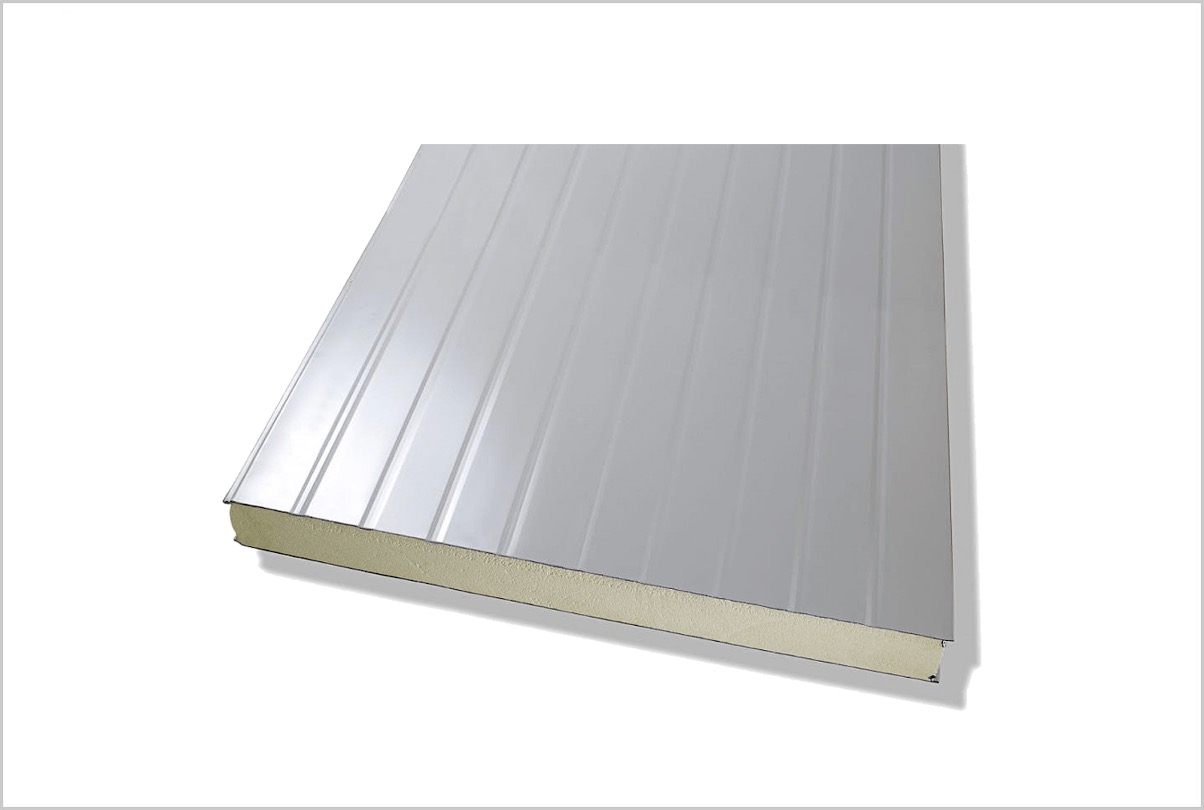

PU foam panels are composed of a core made from PU (Polyurethane) resin with panel thicknesses ranging from 50 to 200mm, depending on specific usage and requirements. The galvanized steel surfaces on both sides of PU foam panels have a thickness ranging from 0.35 to 0.60mm.

With a thermal conductivity coefficient ranging from 0.016 to 0.027 (w/mk), these panels offer impressive thermal insulation. This helps to maintain a stable internal temperature within buildings, reducing energy consumption and enhancing energy efficiency.

PU foam panels are made with a core of PU (Polyurethane) resin

EPS foam panels are another type of insulated metal panel, formed by two galvanized colorbond steel layers, with thicknesses ranging from 0.3 to 0.6 mm, surrounding an EPS foam core. The EPS core has a density ranging from 8 to 14 kg/m3, and the layers are bonded together using specialized adhesive.

With a thermal conductivity coefficient between 0.37 and 0.4 (w/mk), EPS panels provide impressive insulation. These panels are also notable for their soundproofing, thermal insulation, and fire-resistant properties, making them an ideal solution for building applications requiring high-performance insulation.

EPS foam panels are a type of insulated metal panel constructed from two layers of colorbond galvanized steel

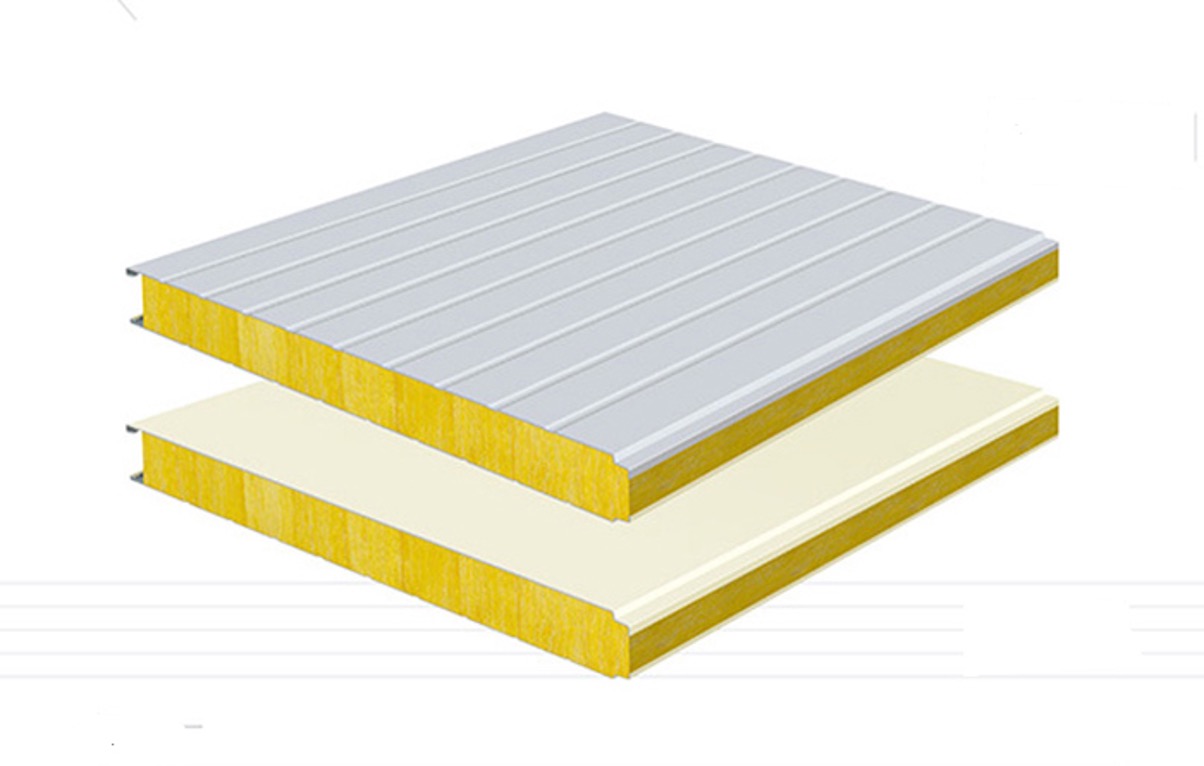

Fiberglass foam insulated panels have a lightweight foam core made from fiberglass, offering high thermal insulation performance. The main materials used in fiberglass foam panels include silicate, aluminum, calcium, metal oxides, and other inorganic compounds. The two outer layers are made of aluminum-zinc alloy coated steel, typically with a thickness ranging from 0.35mm to 0.6mm.

One of the standout advantages of fiberglass foam panels is their excellent fire resistance and thermal insulation properties. Therefore, fiberglass foam insulated panels are widely preferred and used for projects that demand high safety standards and fire resistance.

Fiberglass foam insulated panels have a core structure made from fiberglass foam

Rockwool foam insulated panels, also known as Sandwich Rockwool Panels, are a type of fireproof and soundproof panel with a core made from Rockwool. A notable feature of this core is its non-flammable nature when exposed to fire, unlike other materials that may ignite.

Rockwool panels are designed to withstand extremely high melting temperatures, thanks to the combination of surface coatings on the two layers of color-coated steel and the unique properties of the Rockwool core. Additionally, the product provides outstanding thermal insulation, electrical insulation, and fire resistance, making it an ideal solution for projects requiring high safety standards and reliable thermal and sound insulation.

Rockwool foam panels are fireproof and soundproof panels with a core made from Rockwool

Foam insulated panels are widely favored and used today due to the following outstanding advantages:

These advantages make foam insulated panels an ideal choice for many types of construction, from industrial to residential projects.

Foam insulated panels are widely favored and used today due to their outstanding benefits

Foam panel sheets have diverse applications and are widely used across various fields, as follows:

Thanks to their flexibility, thermal and sound insulation properties, outdoor foam panel sheets are a smart choice for various types of buildings, from healthcare and education to industrial and agricultural applications.

Pomina Steel is a high-quality steel widely used in the production of foam panel sheets. Pomina Steel stands out with its superior characteristics and diverse applications. The prominent features of Pomina Steel include:

Pomina Steel is a high-quality steel sheet widely used in the production of foam insulated panel sheets

Pomina Steel is used as the outer layer of foam insulated panels, protecting the foam core and enhancing the aesthetic appeal of the product. With its corrosion resistance and high durability, Pomina foam sheet increases the lifespan and performance of foam insulated panels in all environmental conditions.

Pomina Steel is an ideal choice for the production of foam insulated panels, offering variety, quality, and high efficiency for construction projects.

Below is the latest price list for foam insulated panel sheets in 2024:

EPS foam core panel sheets (50mm thickness), for interior walls in white, yellow, and cream, using Vietnam-France steel, width 1150 – 1170:

EPS foam core panel sheets (50mm thickness), for interior walls in white, yellow, and cream, using Vietnam-France steel, width 1020 – 1000:

PU foam sheets for interior walls, PU density: 40±2mm. Effective width: 1000mm – 1130mm, approximately 50mm thick, AZ50:

Glass wool foam core panels for walls, density 48 ± 1kg/m3 (Unit: m²), panel thickness approximately 50mm:

Note: Prices above do not include VAT and are only applicable at a specific time. Customers can contact us for more details and the most accurate prices for other products and sizes.

If you’re looking for a reputable supplier and installer of foam insulated panels at reasonable prices in Hanoi, Stavian Industrial Metal is a reliable choice. Here are the reasons customers trust and choose our service:

With our commitments and quality services, Stavian Industrial Metal is confident in being your trusted partner in every construction project. We hope this article has provided a comprehensive overview and better understanding of the benefits, applications, and value of foam insulated panels in construction.

LEARN MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com