In this detailed post, you’ll learn all about sandwich aluminum panels. Explore the structure, categorization, and benefits of these versatile construction materials. Discover how the combination of aluminum sheets and core materials results in lightweight but sturdy panels. Learn about the numerous core material options available, such as polyethylene, polyurethane, and mineral wool, and their respective qualities. Discover the many benefits of sandwich aluminum panels, including thermal insulation, weather resistance, and design flexibility. Whether you’re an architect, builder, or design enthusiast, this article takes a closer look at the amazing qualities that make sandwich aluminum panels a popular choice in modern architecture.

A sandwich panel, also known as a composite panel or structural insulated panel (SIP), is a type of construction material consisting of three layers – two outer layers (skins) and a core material in between. The outer layers are typically made of metal, such as aluminum or steel, but can also be made of other materials like fiberglass or wood. The core material is usually an insulating material, such as polyurethane foam, polystyrene, or mineral wool. The combination of these layers creates a lightweight yet strong panel with excellent thermal and acoustic insulation properties. Sandwich panels are widely used in building construction for walls, roofs, and facades, offering energy efficiency, durability, and design flexibility.

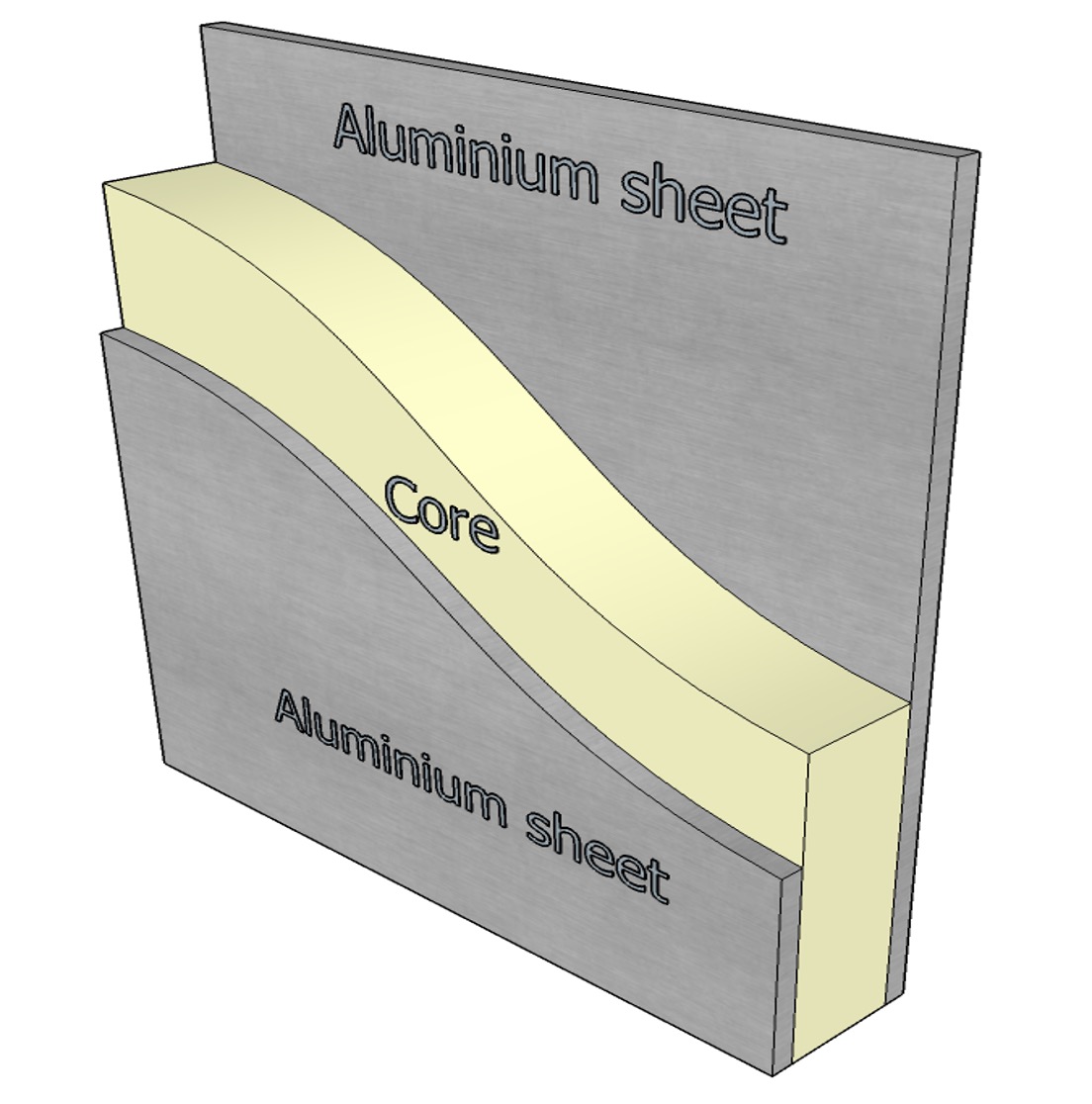

A sandwich aluminum panel typically consists of three main layers: two outer aluminum sheets (also known as skins or face sheets) and a core material sandwiched between them. Below are detailed information of each class:

The combination of the outer aluminum sheets and the core material creates a sandwich structure, where the core acts as a spacer and provides insulation properties while the aluminum sheets contribute to the panel’s strength and protection against environmental factors. The specific composition and design of sandwich aluminum panels can vary depending on the desired performance requirements, such as fire resistance, thermal insulation, soundproofing, and structural strength, among others.

Aluminum sandwich panels can be classified based on various factors, including the core material, application, and construction method. Here are some common classifications:

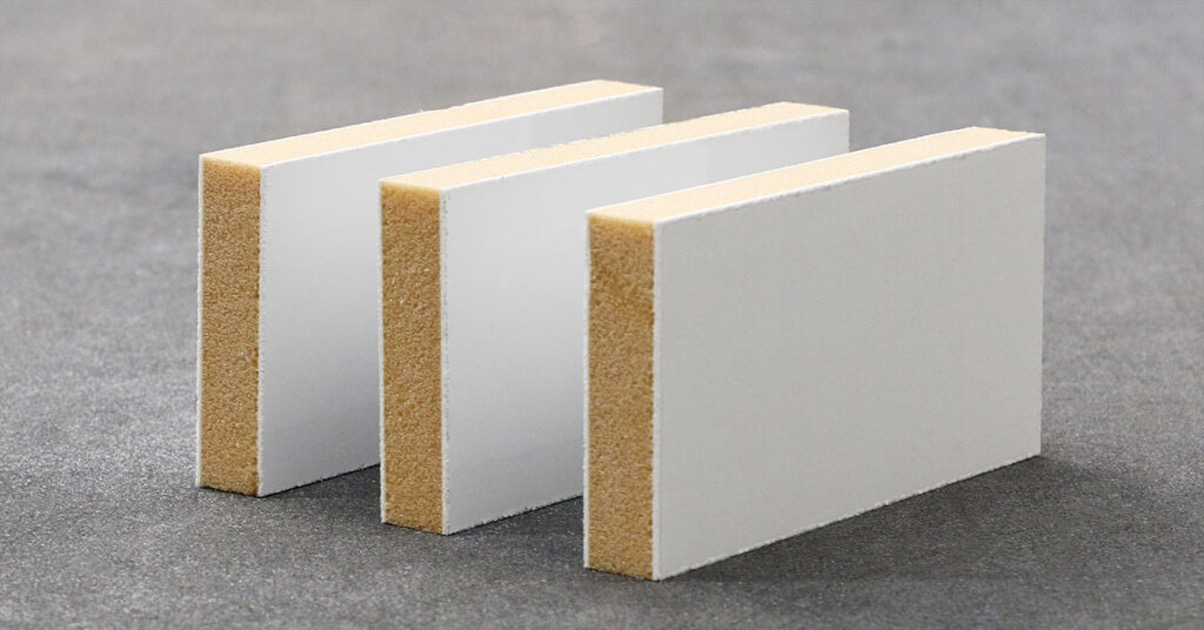

Polyethylene (PE) Core Panels: These panels have a core made of polyethylene material, which is lightweight, cost-effective, and offers good insulation properties. PE core panels are commonly used in applications where weight reduction and basic insulation are desired, such as signage, interior walls, and ceilings.

Polyurethane (PU) Core Panels: Panels with a polyurethane core provide excellent thermal insulation and sound absorption properties. PU core panels are often used in applications where energy efficiency, noise reduction, and climate control are important, such as cold storage facilities, industrial buildings, and residential construction.

Polyvinyl Chloride (PVC) Core Panels: These panels have a PVC core that offers thermal insulation properties and, in some cases, fire resistance. PVC core panels are commonly used in applications where both insulation and fire safety are essential, such as hospitals, schools, and commercial buildings.

Mineral Wool Core Panels: Panels with a mineral wool core offer high fire resistance, acoustic insulation, and thermal properties. They are commonly used in applications where fire safety, soundproofing, and thermal performance are critical, such as theaters, industrial plants, and high-rise buildings.

Wall Panels: Aluminum sandwich panels designed for exterior or interior wall cladding, providing durability, weather resistance, and aesthetic appeal.

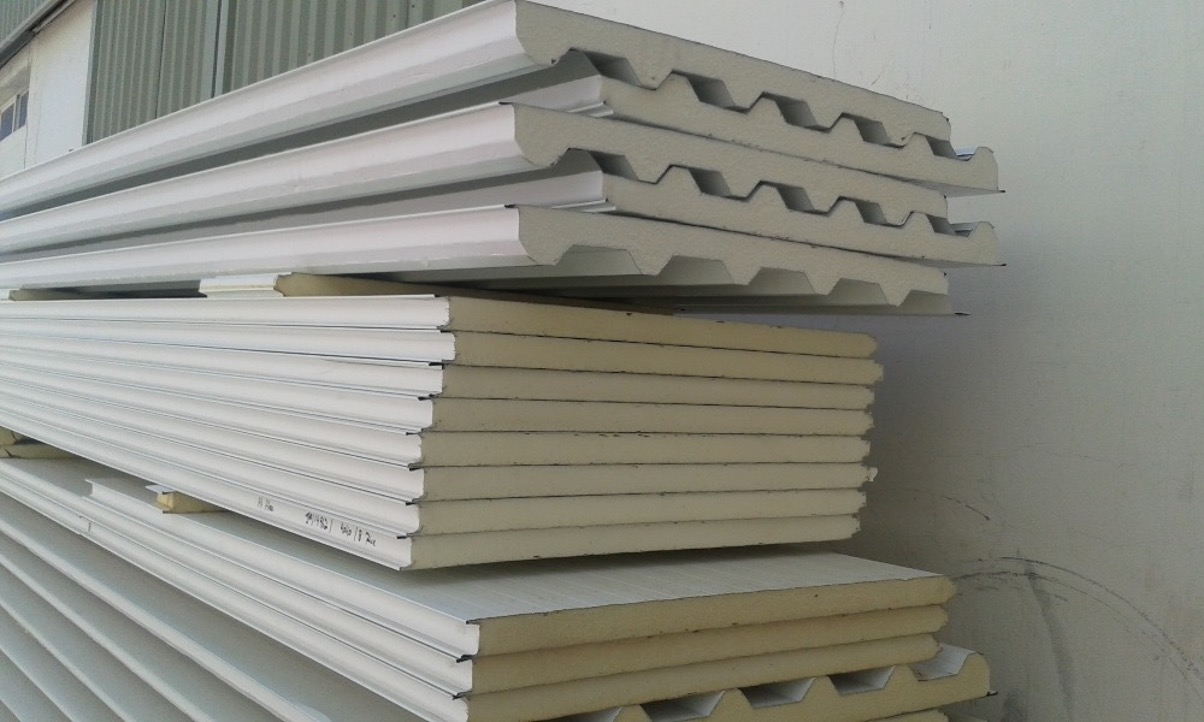

Roofing Panels: Panels specifically engineered for roofing applications, offering protection against the elements, thermal insulation, and water resistance.

Facade Panels: Panels used to create visually appealing facades on buildings, often incorporating design elements, textures, and finishes to enhance the building’s aesthetics.

Signage Panels: Panels tailored for signage applications, providing a durable and customizable surface for outdoor and indoor signage.

Continuous Bonding: Panels constructed by continuously bonding the core material between two aluminum sheets using adhesives or bonding agents. This method ensures a uniform and strong bond throughout the panel.

Discontinuous Bonding: Panels where the core material is placed in discrete sections or dots between the aluminum sheets. This construction method allows for specific structural or insulation properties in targeted areas of the panel while reducing material usage.

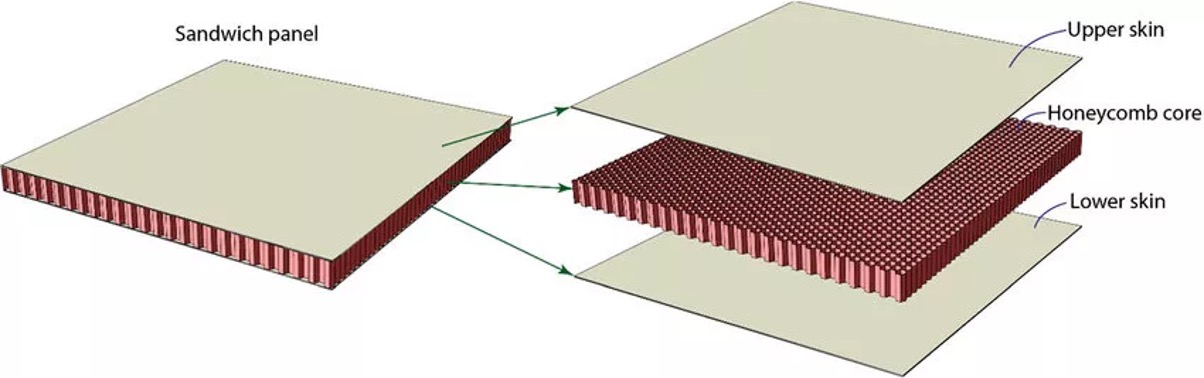

Honeycomb Structure: Panels with a honeycomb core made of aluminum or other materials. The honeycomb structure provides exceptional strength-to-weight ratio, rigidity, and impact resistance. Honeycomb core panels are commonly used in aerospace, marine, and high-performance applications.

These detailed classifications help differentiate aluminum sandwich panels based on core material, application suitability, and construction method, allowing for precise selection and specification of panels based on specific project requirements and performance criteria.

There are several reasons why choosing sandwich aluminum panels can be advantageous. Here are some key benefits:

Lightweight: Sandwich aluminum panels are lightweight compared to solid metal panels, making them easier to handle, transport, and install. This reduces labor and transportation costs and can simplify installation processes.

Strength and Durability: Despite their lightweight nature, sandwich aluminum panels are structurally strong and durable. The combination of the outer aluminum sheets and the core material provides excellent strength and rigidity, making them capable of withstanding external forces and impacts.

Design Flexibility: Sandwich aluminum panels offer design versatility, allowing for customization and creative possibilities. They come in various sizes, shapes, finishes, and colors, enabling architects and designers to achieve unique aesthetic visions and architectural styles.

Thermal Insulation: Sandwich aluminum panels with insulating core materials, such as polyurethane or mineral wool, offer effective thermal insulation. They help to regulate interior temperatures by reducing heat transfer, resulting in energy savings and improved comfort.

Weather Resistance: Aluminum is naturally resistant to corrosion and rust, making sandwich aluminum panels highly durable in various weather conditions. They can withstand exposure to UV rays, moisture, extreme temperatures, and other environmental factors without significant deterioration.

Fire Resistance: Depending on the core material used, sandwich aluminum panels can offer fire-resistant properties. Panels with mineral wool cores, for example, provide excellent fire resistance, making them suitable for applications where fire safety is crucial.

Easy Maintenance: Sandwich aluminum panels require minimal maintenance. They are easy to clean, and their durable surface resists stains, dirt, and pollutants. Regular cleaning with mild detergents and periodic inspections are typically sufficient to keep them in good condition.

Sustainable Choice: Aluminum is a highly recyclable material, and sandwich aluminum panels contribute to sustainability efforts. They can be recycled at the end of their lifespan, reducing waste and conserving natural resources.

Overall, sandwich aluminum panels offer a combination of strength, durability, thermal insulation, weather resistance, and design flexibility. These benefits make them a popular choice for various applications, including building facades, roofing, interior walls, and signage, among others.

In conclusion, sandwich aluminum panels are a remarkable construction material that offers a combination of strength, durability, and versatility. By examining their structure, classification, and advantages, we gain a deeper understanding of their capabilities. The diverse range of core materials available, such as polyethylene, polyurethane, and mineral wool, provides options for various applications and performance requirements. With their lightweight nature, thermal insulation properties, and resistance to weather and fire, sandwich aluminum panels prove to be an excellent choice for building facades, roofing, interior walls, and signage. Their design versatility provides architects and designers with limitless creative options. Embracing sandwich aluminum panels can lead to efficient, sustainable, and visually striking architectural solutions in the modern construction landscape.

EXPLORE MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com