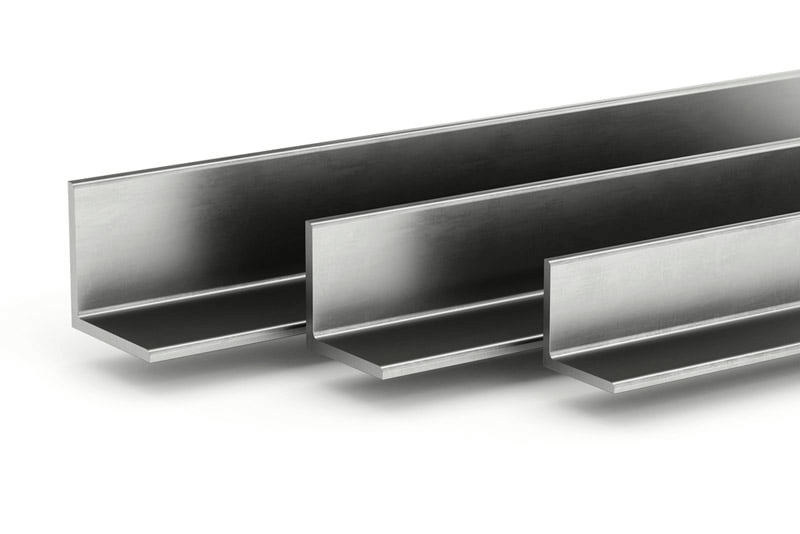

Unequal angle steel, commonly referred to as L-shape steel, is a type of building material with unique characteristics and diverse applications in various industrial and construction sectors. The special feature of L-shape steel compared to other types of steel is its two unequal edges, forming a right angle. Let’s explore this special type of steel with Stavian Metal. Learn about the specific information of L-shape steel and its application in the article below.

L-shape steel, the most widely used building material in every project

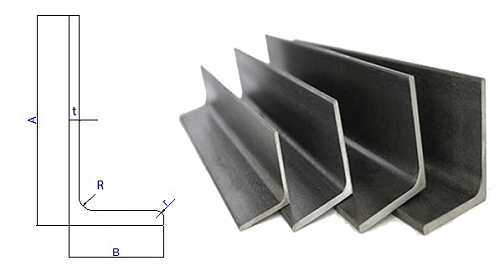

Unequal angle steel, or L-shape steel, is a type of steel product designed and manufactured in the shape of an “L”. The common characteristic of this type of steel is having two unequal edges forming a right angle. L-shape steel is highly regarded for its hardness, strength, and durability, especially in applications requiring high resistance such as in bridge construction and industrial projects.

L-shape steel is also known as unequal angle steel

L-shape steel is often preferred in projects that require high load-bearing capacity due to its high pressure and vibration resistance. Although similar in shape to V-shape steel, these two types of steel still have distinct characteristics and applications.

In particular, the flexibility and adaptability of L-shape steel have made it an essential and indispensable material in the construction and mechanical industries.

L-shape steel is a widely used material in many types of projects, thanks to its ability to withstand high pressure and harsh weather conditions. Below are the common types of L-shape steel:

The tropical humid climate in Vietnam creates favorable conditions for the formation of rust and corrosion in metal materials. Galvanized L-shape steel was born to solve this problem. Galvanized L-shape steel has a zinc coating layer that helps prevent rust and increase the lifespan of the material.

There are three common types of L-shape steel on the current market

Hot-dip galvanized L-shape steel is produced through the hot-dip galvanizing process. The outer zinc coating protects the material from negative environmental effects after production.

Black L-shape steel has a black or dark blue color due to the cooling process with water spray during the steel rolling process. It is widely used in practice with high popularity.

The above types of L-shape steel all have their own applications and characteristics, suitable for the needs and requirements of specific projects.

Each type of L-shape steel has its own advantages and disadvantages suitable for different types of projects

Unequal angle steel is produced according to various standards to meet the usage needs and diversity of different types of projects. Below are some common grades of L-shape steel available on the market today:

Each steel grade has different prices depending on the origin, quality, and production standards. Among these, Chinese steel grades are the most commonly used due to their reasonable prices, diverse designs, and easy availability on the market.

L-shape steel, with its outstanding advantages, is applied diversely in various industries and fields. Specifically:

The lightweight and high load-bearing capacity of L-shape steel are important factors contributing to its flexibility and diversity of applications in various projects and industries.

L-shape steel comes in various sizes to serve different purposes in construction projects. Each project has its own technical requirements, and therefore will use L-shape steel with appropriate dimensions.

The variety of sizes allows designers and engineers to choose the most suitable type of L-shape steel for the specific needs of each project. This helps optimize flexibility and efficiency in constructing structures from small to large.

Detailed formula for calculating the mass of L-shape steel

Example of the specification symbol of hot-rolled L-shape steel: L-shaped steel with dimensions of 60x40x5, named L60x40x5B according to TCVN 1657 – 1993 standard.

The cross-sectional area is calculated by the formula:

S=[t(A+B−t)+0.2416(R2 −2r2)]×1/100

Where:

The mass of 1m length is calculated based on the nominal size and mass of L-shape steel, with a value of 7.85 kg/dm^3.

The formula for calculating the mass of L-shape steel is based on the cross-sectional area and length of the steel bar. The specific formula is as follows:

Mass (m) = Cross-sectional area (S) * Length (L) * Density of steel

Where:

You can use this formula to calculate the mass of L-shape steel based on its dimensions and length.

Here is a detailed chart of type 1 and type 2 L-shape steel:

|

Geometric characteristics |

||||||||||||||||||||

| Standard sizes (mm) | Cross-sectional area (cm2) | Mass (kg/m) | Center of gravity | Moment of inertia | Radius of gyration (cm) | Tan | Bending moment resistance (cm3) | |||||||||||||

| HxB | t1 | t2 | r1 | r2 | Cx | Cy | Ix | Iy | Max Iu | Min Ix | ix | iy | Max ix | Min iy | Wx | wy | ||||

| L200x90 | 9 | 14 | 14 | 7 | 29,66 | 23,3 | 6,36 | 2,15 | 1210 | 200 | 1290 | 125 | 6,39 | 2,6 | 6.58 | 2,05 | 0,263 | 88,7 | 29,2 | |

| L250x90 | 10 | 15 | 17 | 8,5 | 37,47 | 29,4 | 8,61 | 1,92 | 2440 | 223 | 2520 | 147 | 8,08 | 2,44 | 8,2 | 1,98 | 0,182 | 149 | 31,5 | |

| L250x90 | 12 | 16 | 17 | 8,5 | 42,95 | 33,7 | 8,99 | 1,89 | 2790 | 238 | 2870 | 160 | 8,07 | 2,35 | 8,18 | 1,93 | 0,173 | 174 | 33,5 | |

| L300x90 | 11 | 16 | 19 | 9,5 | 46,22 | 36,3 | 11 | 1,76 | 4370 | 245 | 4440 | 168 | 9,72 | 2,3 | 9,8 | 1,9 | 0,136 | 229 | 33,8 | |

| L300x90 | 13 | 17 | 19 | 9,5 | 52,67 | 41,3 | 11,3 | 1,75 | 4940 | 259 | 5020 | 181 | 9,68 | 2,22 | 9,76 | 1,85 | 0,128 | 265 | 35,8 | |

| L350X100 | 12 | 17 | 22 | 11 | 57,74 | 45,3 | 13 | 1,87 | 7440 | 362 | 7550 | 251 | 11,3 | 2,5 | 11,4 | 2,08 | 0,124 | 338 | 44,5 | |

| L400x100 | 13 | 18 | 24 | 12 | 68,59 | 53,8 | 15,4 | 1,77 | 11500 | 388 | 11600 | 277 | 12,9 | 2,38 | 13 | 2,01 | 0,0996 | 468 | 47.1 | |

|

Geometric characteristics |

|||||||||||||||||||

| Standard sizes (mm) | Cross-sectional area (cm2) | Specific weight | Center of gravity | Moment of inertia | Radius of gyration (cm) | Tan | Bending moment resistance (cm3) | ||||||||||||

| HxB | t | r1 | r2 | Cx | Cy | Ix | Iy | Max Iu | Min Ix | ix | iy | Max ix | Min iy | Wx | Wy | ||||

| L90X75 | 9 | 8,5 | 6 | 14,04 | 11,0 | 2,75 | 2,00 | 109,0 | 68,81 | 143,0 | 34,1 | 2,78 | 2,20 | 3,19 | 1,56 | 0,68 | 17,40 | 12,40 | |

| L100x75 | 7 | 10 | 5 | 11,87 | 9,32 | 3,06 | 1,83 | 118,0 | 56,9 | 144 | 30,8 | 3,15 | 2,19 | 3,49 | 1,61 | 0,55 | 17,00 | 10,00 | |

| L100x75 | 10 | 10 | 7 | 16,50 | 13,00 | 3,17 | 1,94 | 159,0 | 76,1 | 194,0 | 41,3 | 3,11 | 2,15 | 3,43 | 1,58 | 0,54 | 23,30 | 13,70 | |

| L125x75 | 7 | 10 | 5 | 13,62 | 10,70 | 4,10 | 1,64 | 219,0 | 60,4 | 243,0 | 36,4 | 4,01 | 2,11 | 4,23 | 1,64 | 0,36 | 26,10 | 10,30 | |

| L125x75 | 10 | 10 | 7 | 19,00 | 14,90 | 4,22 | 1,75 | 299,0 | 80,8 | 330,0 | 49,0 | 3,96 | 2,06 | 4,17 | 1,61 | 0,36 | 36,10 | 14,10 | |

| L125x75 | 13 | 10 | 7 | 24,31 | 19,10 | 4,35 | 1,87 | 376,0 | 101,0 | 415,0 | 61,9 | 3,93 | 2,04 | 4,13 | 1,60 | 0,35 | 46,10 | 17,90 | |

| L125x90 | 10 | 10 | 7 | 20,50 | 16,10 | 3,95 | 2,22 | 318,0 | 138,0 | 380,0 | 76,2 | 3,94 | 2,59 | 4,30 | 1,93 | 0,51 | 37,20 | 20,30 | |

| L125x90 | 13 | 10 | 7 | 26,26 | 20,60 | 4,07 | 2,34 | 401,0 | 173,0 | 477,0 | 96,3 | 3,91 | 2,57 | 4,26 | 1,91 | 0,50 | 47,50 | 25,90 | |

| L150x90 | 9 | 12 | 6 | 20,94 | 16,40 | 4,95 | 1,99 | 485,0 | 133,0 | 537,0 | 80,4 | 4,81 | 2,52 | 5,06 | 1,96 | 0,36 | 48,20 | 19,00 | |

| L150x90 | 12 | 12 | 8,5 | 27,36 | 21,50 | 5,07 | 2,10 | 619,0 | 167,0 | 685,0 | 102,0 | 4,76 | 2,47 | 5,00 | 1,93 | 0,36 | 62,30 | 24,30 | |

| L150x100 | 9 | 12 | 6 | 21,84 | 17,10 | 4,76 | 2,30 | 502,0 | 181,0 | 579,0 | 104,0 | 4,79 | 2,88 | 5,15 | 2,18 | 0,44 | 49,10 | 23,50 | |

| L150x100 | 12 | 12 | 8,5 | 28,56 | 22,40 | 4,88 | 2,41 | 642,0 | 228,0 | 738,0 | 132,0 | 4,14 | 2,83 | 5,09 | 2,15 | 0,44 | 63,40 | 30,10 | |

| L150x100 | 15 | 12 | 8,5 | 35,25 | 27,70 | 5,00 | 2,53 | 782,0 | 276,0 | 897,0 | 161,0 | 4,71 | 2,80 | 5,04 | 2,14 | 0,43 | 78,20 | 37,00 | |

Below is the price list for L-shape steel at Stavian Metal. Refer to this price list to get an overview of the L-shape steel prices, but note that prices may vary depending on market conditions. Please contact the supplier directly for detailed information.

| Specifications

(mm) |

Length

(m) |

L-shape Steel Weight

(Kg/piece) |

Unit Price of L-shape steel including VAT

(VNĐ/Kg) |

|

| L Steel 30x 30x 3 | 6 | 8.16 | Contact | |

| L Steel 40x 40x 3 | 6 | 11.10 | ||

| L Steel 40x 40x 4 | 6 | 14.52 | ||

| L Steel 50x 50x 4 | 6 | 18.30 | ||

| L Steel 50x 50x 5 | 6 | 22.62 | ||

| L Steel 63x 63x 5 | 6 | 28.86 | ||

| L Steel 63x 63x 6 | 6 | 34.32 | ||

| L Steel 70x 70x 5 | 6 | 32.28 | ||

| L Steel 70x 70x 6 | 6 | 38.34 | ||

| L Steel 70x 70x 7 | 6 | 44.34 | ||

| L Steel 75x 75x 5 | 6 | 34.80 | ||

| L Steel 75x 75x 6 | 6 | 41.34 | ||

| L Steel 75x 75x 7 | 6 | 47.76 | ||

| L Steel 80x 80x 6 | 6 | 44.16 | ||

| L Steel 80x 80x 7 | 6 | 51.06 | ||

| L Steel 80x 80x 8 | 6 | 57.90 | ||

| L Steel 90x 90x 6 | 6 | 50.10 | ||

| L Steel 90x 90x 7 | 6 | 57.84 | ||

| L Steel 90x 90x 8 | 6 | 65.40 | ||

| L Steel 100x 100x 8 | 6 | 73.20 | ||

| L Steel 100x 100x 10 | 6 | 90.60 | ||

| L Steel 120x 120x 8 | 12 | 176.40 | ||

| L Steel 120x 120x 10 | 12 | 219.12 | ||

| L Steel 120x 120x 12 | 12 | 259.20 | ||

| L Steel 125x 125x 10 | 12 | 229.20 | ||

| L Steel 125x 125x 15 | 12 | 355.20 | ||

| L Steel 130x 130x 10 | 12 | 237.00 | ||

| L Steel 130x 130x 12 | 12 | 280.80 | ||

| L Steel 150x 150x 10 | 12 | 274.80 | ||

| L Steel 150x 150x 12 | 12 | 327.60 | ||

| L Steel 150x 150x 15 | 12 | 405.60 | ||

| L Steel 175x 175x 12 | 12 | 381.60 | ||

| L Steel 175x 175x 15 | 12 | 472.80 | ||

| L Steel 200x 200x 15 | 12 | 543.60 | ||

| L Steel 200x 200x 20 | 12 | 716.40 | ||

| L Steel 200x 200x 25 | 12 | 888.00 |

Based on the detailed information provided, you now have an overview of L-shape steel. Stavian hopes that with information on the dimensions and specifications of L-shape steel, as well as prices and prominent features and applications of L-shape steel, you can choose the suitable type of steel for your construction project to achieve the best quality.

FOR FURTHER REFERENCE

If customers want to purchase L-shape steel and need to update the latest price information, please contact Stavian Metal via the following information:

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com