High-frequency furnace steel billet is an extremely important and promising material in the construction and manufacturing industries. Using the principle of electromagnetic induction, high-frequency furnace steel billets are heated to high temperatures, resulting in exceptional toughness, durability, heat resistance, and oxidation resistance. Throughout the production, processing, and construction processes, high-frequency furnace steel billets provide rapid response and high performance, saving time and costs. Let’s delve into this type of steel billet from the high-frequency furnace in the following article.

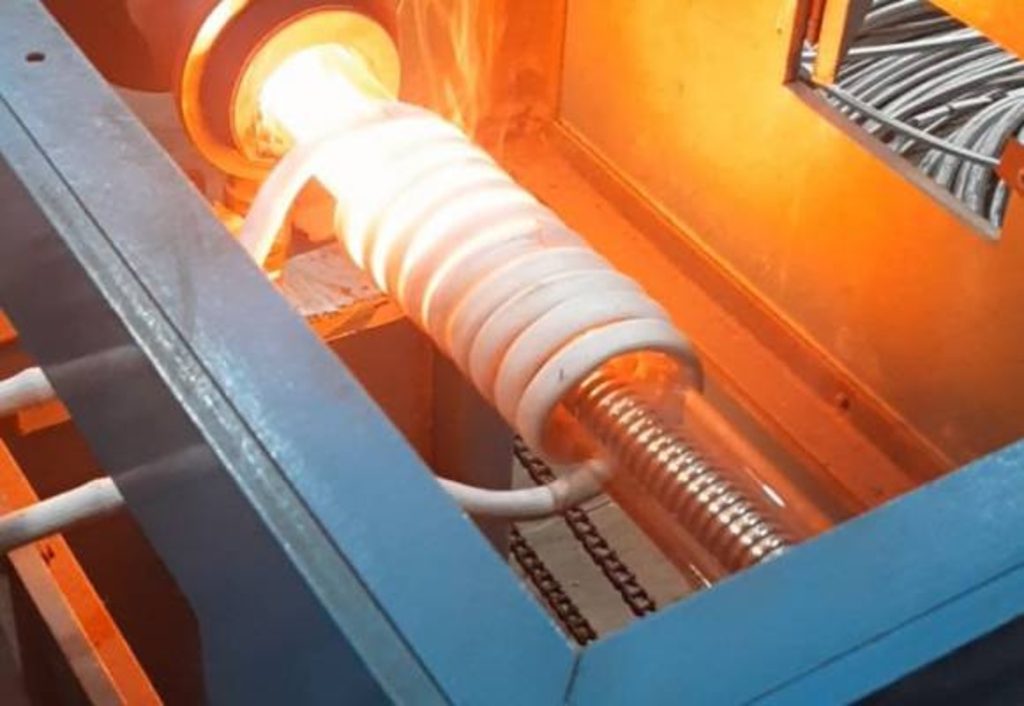

A high-frequency furnace is a device used in the steel industry to melt iron ore and other raw materials to produce steel. It is called “high-frequency” because it utilizes high-frequency alternating current to generate the heat required for melting the materials.

High-frequency furnaces are capable of generating extremely high temperatures, ranging from approximately 1,500 to 2,000 degrees Celsius, to melt iron ore and other compounds into a liquid state. After the melting process, this liquid steel is poured into molds to create steel billets, which are further processed and used in various industries, including construction.

High-frequency furnace steel billets are products created during the melting process of iron ore and other raw materials in a high-frequency furnace. This process is typically carried out in steel manufacturing plants. The iron ore and other materials are melted at very high temperatures, ranging from 1,500 to 2,000 degrees Celsius, in the high-frequency furnace.

Once the molten steel is formed, it is poured into molds to create steel billets with desired shapes and sizes. These high-frequency furnace steel billets are then further processed and used in various industries, including construction, automotive, shipbuilding, and many other applications.

High-frequency furnace steel billets possess several notable characteristics and properties.

Firstly, they exhibit excellent heat resistance. The high melting temperatures during the production process enable high-frequency furnace steel billets to withstand high-temperature environments without deforming or losing their mechanical properties. This makes them ideal for applications in high-temperature environments, such as in metallurgical industries, energy, and construction of structures with stringent temperature requirements.

Secondly, high-frequency furnace steel billets have high strength. With their special crystal structure and precise melting process, these billets can withstand substantial impact forces and loads without easy deformation or damage. This property makes high-frequency furnace steel billets widely used in applications that demand robust mechanical properties, such as constructing load-bearing structures and infrastructure.

SEE MORE : Mid-frequency furnace: process of producing steel billets

High-frequency furnace steel billets have high flexibility and durability, allowing them to withstand strong impacts and forces without deforming or fracturing. This makes them a preferred choice for constructing load-bearing structures, bridges, and industrial structures requiring high strength and safety.

Thanks to their excellent heat resistance, high-frequency furnace steel billets can withstand high-temperature environments without losing their mechanical properties.

High-frequency furnace steel billets have the advantage of quick response in processing and construction. With easy machinability, they can be cut, welded, bent, and processed into high-precision products. This brings benefits in terms of time efficiency and project schedules in construction and manufacturing, increasing productivity and reducing production costs.

High-frequency furnace steel billets find widespread use in various industries due to their outstanding characteristics.

In the construction industry, high-frequency furnace steel billets are used to create load-bearing structures such as columns, beams, frames, and foundations. Their high strength and durability ensure the construction of sturdy and secure buildings, bridges, warehouses, and ports.

High-frequency furnace steel billets are utilized in the production of industrial machinery and equipment. Their high load-bearing capacity and strength make them suitable for manufacturing machine parts, shafts, gears, and other critical components.

In the automotive and engine manufacturing sector, high-frequency furnace steel billets are used to create essential load-bearing components, such as car frames and transmissions.

Using high-frequency furnace steel billets significantly increases production efficiency and reduces processing time. The fast and efficient processing enables higher batch production, reducing waiting times, and enhancing production line efficiency.

Using high-frequency furnace steel billets also brings cost-saving benefits and production process optimization. With their high flexibility, durability, and load-bearing capacity, these billets minimize material wastage due to deformation and ensure stability in the production process. Additionally, advanced processing techniques and automation further optimize the production process and reduce errors.

Thanks to their uniform and stable properties, high-frequency furnace steel billets ensure consistency and uniformity in the manufactured products. This not only guarantees strong and reliable mechanical properties but also creates high reliability, minimizing risks and improving safety during usage.

In conclusion, high-frequency furnace steel billets are a vital material in various industries due to their exceptional properties and advantages. Their flexibility, durability, heat resistance, and rapid response in processing and construction make them valuable components in building robust structures and producing reliable industrial products.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com