Step-by-Step Explanation of the Hot Dip Galvanizing Process

Discover everything you should know about Galvalume steel coils in this comprehensive guide. Explore the composition, properties, and advantages of Galvalume steel coils, including their superior corrosion resistance and durability. Gain insights into the various applications and industries where Galvalume steel coils are used. Understand the factors affecting the price of Galvalume steel coils. Whether you’re a contractor, architect, or in the manufacturing industry, this guide will provide you with valuable information to make informed decisions. Expand your knowledge and make the most out of Galvalume steel coils with this comprehensive resource.

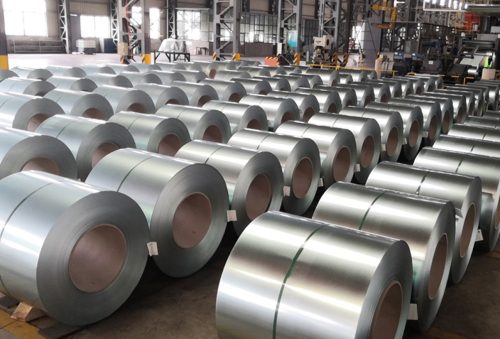

Galvalume steel coils, also known as Aluzinc steel coils, are a type of coated steel product that combines the corrosion resistance of aluminum with the galvanic protection of zinc. The term “Galvalume” is a registered trademark owned by BIEC International Inc., and it refers specifically to their product.

Galvalume steel is made by coating a steel substrate with a mixture of aluminum, zinc, and silicon. The coating is applied through a continuous hot-dip process, where the steel coil is immersed in a molten bath of the coating material. The coating composition typically consists of approximately 55% aluminum, 43.5% zinc, and 1.5% silicon.

The combination of aluminum and zinc offers excellent corrosion resistance, as both metals have inherent protective properties. The aluminum provides a self-healing mechanism, forming a thin, transparent oxide layer that prevents further corrosion, while the zinc acts as a sacrificial anode, protecting the underlying steel from rust.

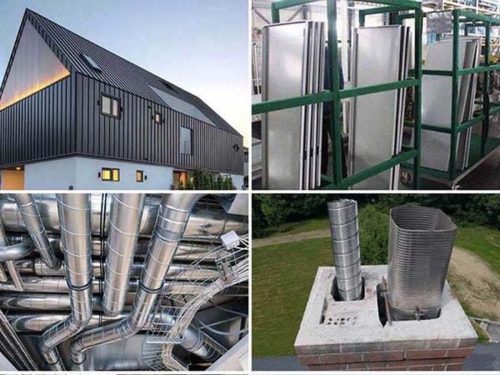

Galvalume steel coils are widely used in the construction industry for roofing, cladding, and other applications requiring corrosion-resistant and durable materials. They offer a longer lifespan compared to traditional galvanized steel and are known for their superior resistance to atmospheric corrosion, heat, and sunlight exposure.

Prepainted Galvalume steel coils are Galvalume steel coils that have been further processed with a pre-applied paint coating. The Galvalume steel substrate provides excellent corrosion resistance, while the pre-painted coating enhances the aesthetic appeal and adds additional protection.

The prepainting process involves applying a layer of paint to the Galvalume steel coils through a continuous coil coating line. The coils are first cleaned and treated to ensure proper adhesion of the paint. Then, a primer is applied to enhance adhesion and provide a smooth base for the topcoat. Finally, a topcoat of paint is applied, which can be in a wide range of colors and finishes.

Prepainted Galvalume steel coils offer several advantages. They combine the corrosion resistance and durability of Galvalume steel with the versatility and aesthetics of the pre-painted finish. The pre-applied paint provides an additional layer of protection against environmental elements, such as UV radiation and moisture, while also allowing for customization in terms of color and design.

These coated steel coils are widely used in various applications, including roofing, wall cladding, garage doors, appliances, and other architectural and industrial applications. They offer a durable, attractive, and low-maintenance solution for projects that require both corrosion resistance and aesthetic appeal.

Prepainted Galvalume steel coils and prime prepainted Galvalume steel coils are similar in that they both refer to Galvalume steel coils that have undergone a pre-coating process with a paint system. However, there is a distinction between the two terms:

Prepainted Galvalume steel coils refer to Galvalume steel coils that have been pre-coated with a paint system. These coils come in various colors and finishes, offering versatility and customization options for different applications. Prepainted Galvalume steel coils provide aesthetic enhancement and additional protection against environmental elements such as UV radiation and moisture. These coils are widely used in applications where both functionality and visual appeal are important.

Prime prepainted Galvalume steel coils are a subset of prepainted Galvalume steel coils that meet higher quality standards. The term “prime” signifies that these coils are of superior quality, free from defects or imperfections, and adhere to strict industry standards. Prime prepainted Galvalume steel coils undergo stringent quality control measures during the manufacturing process to ensure consistent and reliable performance. These coils are sought after in applications where a high level of durability, corrosion resistance, and visual aesthetics is required.

In summary, while both prepainted Galvalume steel coils and prime prepainted Galvalume steel coils are coated with a paint system, the term “prime” distinguishes the latter as a higher quality subset that meets strict quality standards. Prime prepainted Galvalume steel coils are known for their superior performance, durability, and aesthetic appeal.

The HS code for Galvalume steel coils refers to the Harmonized System code, which is an internationally recognized system for classifying and categorizing traded products. HS codes are used to standardize and facilitate international trade by assigning a unique code to each product.

In the case of Galvalume steel coils, the HS code is a numerical code that specifically identifies this particular type of product for import and export purposes. The code is used by customs authorities and other trade entities to classify and track the movement of Galvalume steel coils across borders. It helps in determining import duties, taxes, and customs procedures applicable to these products.

HS codes are organized into different sections, with each section representing a specific category of products. The code HS Galvalume steel coils falls under the broader category of iron and steel products. The specific code may vary depending on the country, as different countries may have their national variations of the HS code system.

By using the code HS Galvalume steel coils, importers, exporters, and customs authorities can accurately identify and classify these products, ensuring compliance with trade regulations and facilitating smooth international trade transactions.

Some specific regulations and standards may apply to the import/export of Galvalume steel coils. These regulations and standards can vary depending on the country or region involved. Here are some examples of international standards and regulations related to Galvalume steel coils:

International Organization for Standardization (ISO): ISO has standards related to steel and steel products, including those used for Galvalume coatings. For example, ISO 9364:2017 specifies the requirements for continuously hot-dip coated steel sheets and strips containing aluminum and zinc.

American Society for Testing and Materials (ASTM): ASTM has several standards related to Galvalume steel, such as ASTM A792/A792M, which covers the requirements for steel sheet, 55% aluminum-zinc alloy-coated by the hot-dip process.

European Committee for Standardization (CEN): CEN has standards for coated steels, including Galvalume coatings. For instance, EN 10346:2015 specifies requirements for continuously hot-dip coated steel flat products for cold forming.

National Standards: Many countries have their national standards for Galvalume steel coils. For instance, in the United States, the American Iron and Steel Institute (AISI) provides guidelines and standards for Galvalume steel, such as AISI Specification G550.

In addition to standards, import/export regulations, customs requirements, and trade policies also apply. These can include documentation requirements, customs duties, tariffs, and compliance with specific import/export regulations of the respective countries involved. It is crucial to consult with customs authorities, trade organizations, or legal experts in specific countries to ensure compliance with the applicable regulations and standards when importing or exporting Galvalume steel coils.

The price of Galvalume steel coils can be influenced by several factors. Here are some important aspects that can influence pricing:

Raw Material Costs: The cost of the raw materials used to produce Galvalume steel coils, such as steel, aluminum, zinc, and silicon, can have a significant impact on the overall price. Fluctuations in the prices of these raw materials, influenced by factors like supply and demand dynamics, global market conditions, and trade policies, can impact the cost of Galvalume steel coils.

Production and Manufacturing Costs: The production and manufacturing costs involved in producing Galvalume steel coils, including labor costs, energy costs, equipment maintenance, and operational expenses, can contribute to the final price. Factors such as wage rates, energy prices, and production efficiency can influence these costs.

Market Demand and Supply: The demand for Galvalume steel coils in the market can affect the price. Scarcity may cause prices to rise if demand exceeds supply. Conversely, if the supply surpasses the demand, prices may decrease due to increased competition.

Currency Exchange Rates: Exchange rate fluctuations can impact the price of Galvalume steel coils, especially in international trade. If the currency in which Galvalume steel coils are traded weakens against the currency of the buyer, it can lead to higher prices for the buyer.

Market Competition: The level of competition among suppliers and manufacturers of Galvalume steel coils can influence the pricing. When there is intense competition, suppliers may adjust their prices to attract customers or gain a competitive advantage.

Quality and Specifications: The quality, specifications, and additional features of Galvalume steel coils can affect the price. Higher-quality coatings, customized specifications, or additional performance characteristics may command a higher price compared to standard offerings.

Trade Policies and Tariffs: Trade policies, import/export regulations, and tariffs imposed by governments can impact the price of Galvalume steel coils. Tariffs and duties levied on imported Galvalume steel coils can increase their price in certain markets.

Learn more

Hot Dipped Galvanized Steel Coils: What You Should Know

Top 10 Domestic and Global Galvanized Steel Coil Suppliers

Galvanized Steel Coils: Essential Information You Need to Know

Step-by-Step Explanation of the Hot Dip Galvanizing Process

In conclusion, this comprehensive guide has provided vital insights into Galvalume steel coils, providing you with critical information about their composition, features, and benefits. You’ve learned about Galvalume steel coils’ exceptional corrosion resistance and durability, which makes them a dependable choice for a variety of applications and industries. Understanding the elements influencing the price of Galvalume steel coils allows you to make informed selections that are tailored to your requirements. Whether you work in construction, manufacturing, or another industry, the knowledge offered here will help you maximize the benefits of Galvalume steel coils. With this expertise, you can include Galvalume steel coils into your projects with confidence, assuring long-lasting and high-performance results.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com