Pre-engineered buildings (or Prefab steel houses) are one of the most common forms of residential construction abroad. In Vietnam, this is still a relatively unfamiliar concept. If you’re wondering what prefab steel houses are and what their advantages are, let’s explore the answers in detail through the article below.

Did you know: Differentiating hot-rolled and cold-rolled steel

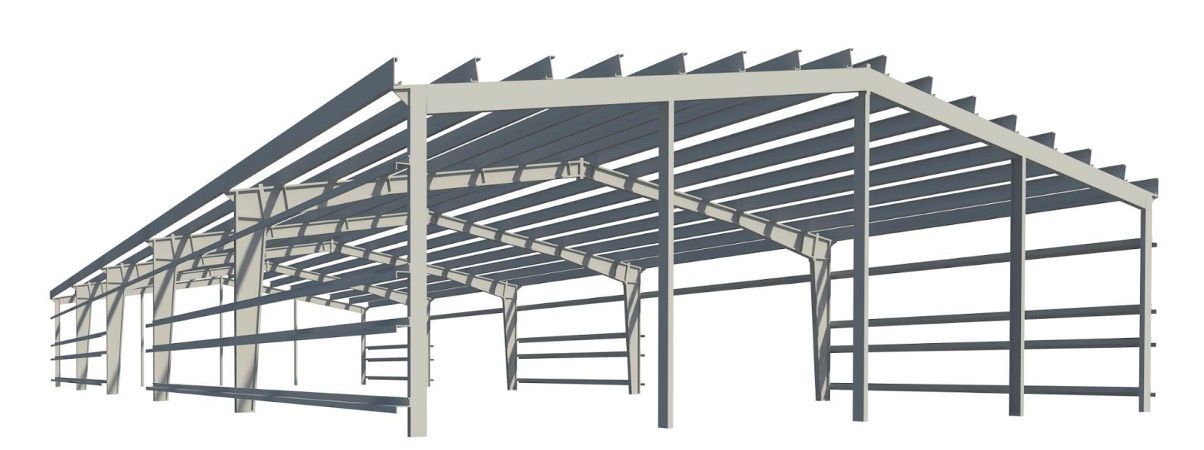

Pre-engineered buildings, often referred to as prefab steel houses, are a type of construction structure primarily made of steel. These structures are manufactured in factories according to specific technical drawings, with precise quantities and dimensions for each component. After successful fabrication, steel components are assembled to complete the preliminary framework of the construction.

Currently, due to the increasing living standards in our country, the demand for pre-engineered buildings is also on the rise because of the following advantages:

1. High industrialization: Prefabricated steel houses are manufactured with a high degree of industrialization, allowing for efficient production in controlled factory conditions.

2. Structural strength: These structures are known for their exceptional load-bearing capacity and resistance to deformation.

3. Rapid design and construction: Steel components are often pre-fabricated or mass-produced in factories, leading to quick assembly and installation on-site.

4. Watertightness: Prefabricated steel houses are designed to be watertight, preventing water infiltration.

5. Labor efficiency: These structures reduce the need for extensive on-site labor during construction.

6. Scalability: Prefabricated steel structures are highly adaptable for expanding the scale of a project.

7. Efficient space utilization: They allow for maximum space utilization in warehouse and industrial settings.

Prefabricated steel houses have significant value in real-life applications, especially in projects that demand durability, such as warehouses, hospitals, high-rise buildings, schools, airports, and more.

This system of construction is highly versatile, making it suitable for a wide range of functions and requirements in business projects. This is one of the most compelling reasons why prefabricated steel houses are the preferred choice for many companies in the construction of warehouses, hospitals, storage facilities, and more.

In addition to the useful advantages mentioned above, pre-engineered steel buildings still have some minor limitations in their usage.

First, we need to consider the structural integrity of these buildings. In the event of unforeseen risks, pre-engineered steel structures are susceptible to collapsing. To address this issue, most modern prefabricated steel buildings apply an effective fire-resistant coating to improve their structural durability.

Because the primary material used in prefabricated steel houses is steel, they are prone to corrosion and rust over time. To enhance the longevity of these structures, steel frames are typically pre-coated and regularly painted with protective coatings. This not only ensures structural integrity but also adds aesthetic value to the building.

Learn more: Table of Shape Steel Specifications

Currently, there are four common types of prefabricated steel buildings on the market:

1. Residential Prefabricated Houses: These are the most common type used for residential purposes. They come in a variety of designs, and their construction costs are relatively affordable. Moreover, the construction process for these buildings is relatively quick, ensuring minimal time investment.

2. Industrial Prefabricated Buildings: These are widely used as warehouses or factories.

3. Commercial Prefabricated Buildings: These are ideal for applications such as grocery stores, supermarkets, convenience stores, or shopping centers.

4. Military Prefabricated Buildings: These are primarily designed for military use, including constructing military bases and camps.

Learn more: What is U100 steel beam?

As a special type of construction, prefabricated steel buildings are typically structured as follows::

Similar to concrete houses, pre-engineered steel buildings must have a foundation to support the entire structure. Depending on the purpose and requirements, foundations can be shallow or deep. For large construction projects, deep foundations are essential to ensure maximum stability. Foundations aside, the main structure includes the following components: the floor, the bracing system, columns, and roof trusses, all of which are crucial as they bear the entire weight of the building.

Secondary structures encompass various components such as partitions, purlins, flooring, walls, skylights, and canopy roofs. While considered secondary, these parts contribute significantly to the overall construction, providing additional strength and finishing touches to ensure the building’s structural integrity.

Cladding and shape structures play a vital role in the construction of prefabricated steel buildings. They include materials like cement board for floor lining, metal roofing sheets, and steel floor lining sheets. These elements are essential for limiting space, protecting the building from external environmental factors, and contributing to the aesthetics of the structure.

Between prefabricated steel buildings and reinforced concrete buildings, there are several key differences:

Unlike the construction process of reinforced concrete buildings, which involves steps such as formwork installation, steel reinforcement, and concrete pouring, prefabricated steel buildings use a different approach.

In the prefabricated steel building process, the steel frame is entirely assembled from steel components. All structural elements, including columns, beams, and floors, are manufactured in factories and then transported to the construction site for assembly. This method saves a significant amount of time and reduces the need for a large workforce to complete the construction.

Prefabricated steel buildings are designed to have a minimum lifespan of 30 years. For larger projects such as restaurants, high-rise buildings, and shopping centers, the steel frame can achieve a lifespan of up to 100 years, meeting the highest durability requirements for modern construction needs.

In the past, steel-framed structures were primarily used in industrial applications, such as warehouses and factories. However, in recent times, steel structures have become more common and are widely used in various civil construction projects, including restaurants, high-rise residential buildings, showrooms, and shopping centers.

The versatility and strength of steel structures make them suitable for a broad range of applications in both industrial and commercial settings.

Learn more: What is HRC steel, what is it used for?

Typically, the construction process for pre-engineered steel buildings is commonly applied to new civil construction projects and involves the following steps:

Conceptual Design and Technical Requirements: Initially, a construction plan is drafted, which includes an overview of the steel structure, architectural drawings, and 3D modeling. This plan outlines construction solutions and technical specifications required for the project.

Foundation Work: Construction begins with the preparation of the building’s foundation at the site. Simultaneously, the main steel components (steel frames, steel beams) are manufactured in the factory.

Steel Frame Assembly: The steel frame, including columns and beams, is assembled on-site according to the architectural design.

Completion of the Building: Once the steel frame is in place, the remaining parts of the building, such as walls, floors, and roofing, are installed.

Project Warranty: Finally, the construction project is completed, and the building is inspected and handed over to the owner. A warranty period may be provided to ensure the quality and durability of the structure.

To provide a pricing estimate for prefabricated steel buildings, several factors come into play:

Whether the design and construction of a prefabricated steel building are large or small in scale significantly impacts the construction cost. Larger-scale projects naturally incur higher construction costs.

Additionally, complex design features will directly correlate with increased construction expenses.

For instance, if there are extensive requirements for systems like air conditioning, lighting, or thermal insulation, the construction cost will rise substantially. Moreover, the inclusion of numerous supplementary design elements such as walkways, staircases, canopies, or cranes will also have a substantial impact on the overall cost of constructing a prefabricated steel building.

The technology used to create products, such as corrosion-resistant materials, color retention, or thermal reflectivity, as well as products customized for specific project needs like anti-rust sheets, regular screw-fastened sheets, large rain gutter sheets for rainy areas, sliding doors, staircases, etc., results in varying prices for each type of material, depending on the different requirements.

Learn more: What is rebar steel? Specifications, Standards, Quotation

The cost of constructing a pre-engineered steel building will depend on several typical factors such as location, project details, environmental conditions, and more.

Moreover, this cost can also vary depending on the construction schedule or the specific materials requested by the customer.

Some additional items include:

For the most accurate quotation and the best consultation on this product, you can contact the company directly to get more information about the prices and the optimal plan.

We can guarantee that we provide the highest quality products at highly competitive prices with lifelong favorable services for all customers.

Here are some questions that we have gathered and are sharing with you regarding pre-engineered steel buildings, which are currently of great interest. Stavian hopes that you will contribute more useful insights to provide feedback to us. Or if you have any questions, you can contact our company directly for free support and answers.

The construction and building process of a prefabricated steel house is much shorter than that of reinforced concrete structures, approximately 30-50% less time. The duration depends on the scale of the project or any additional requirements from the investor. For example, a 1,000m² prefabricated steel workshop can be constructed in about 15-20 days.

The cost of constructing a prefabricated steel building depends on the following factors:

Currently, the design approach using steel as the primary material meets all requirements and standards. Similar to the construction of reinforced concrete buildings, prefabricated steel buildings must adhere to relevant technical standards and codes, such as Eurocode 4 (Design of composite steel and concrete structures), Eurocode 3 (Design of steel structures), TCVN 5575-2012 (Steel structures – Design code), AISC 360 (Specification for Structural Steel Buildings), and more.

Meeting these technical standards ensures that the structure of prefabricated steel buildings is robust and significantly increases their lifespan, making them as durable as traditional reinforced concrete buildings.

Steel, being a material with high strength, uniformity, and inertial properties, allows for the creation of various details and structures tailored to specific needs in prefabricated steel buildings. There is no need to adhere to pre-existing templates or molds.

Therefore, prefabricated steel buildings offer a high degree of customization and can exhibit a distinctive style compared to conventional construction methods.

In practice, not every scale or size of construction project is cost-effective or suitable for prefabricated steel buildings. Prefabricated steel structures are typically more cost-effective for larger-scale projects.

For example, for prefabricated steel warehouses, a minimum width of greater than 17 meters is often necessary to realize cost savings. Smaller-scale projects with widths less than 17 meters may be better suited to traditional reinforced concrete structures.

Similarly, for residential projects such as shops, cafes, restaurants, or townhouses, a minimum width of greater than 5 meters is recommended for considering prefabricated steel structures to optimize cost. Projects with widths less than 5 meters may be more cost-effective with traditional reinforced concrete structures.

In practice, steel frame prefabricated houses offer many advantages over traditional construction methods, including cost savings, shorter construction times, and overall structural load-bearing capacity.

However, when it comes to long-term durability and resilience, steel frame prefabricated houses may not match the durability of traditional reinforced concrete structures. Therefore, the decision to use steel frame prefabricated houses or not depends on individual preferences, budget constraints, and specific project requirements.

Because of the high safety requirements, prefabricated steel buildings are more suitable for flexible projects such as cafes, tea shops, and restaurants. Due to these characteristics, this type of building is not widely preferred for the needs of the local population in our country.

The assembly process of prefabricated steel buildings involves mechanical installation, and construction primarily relies on machinery and equipment. Therefore, such designs may not be applicable in areas with terrain challenges, particularly in urban settings.

In regions with hot climates, prefabricated steel buildings may not be the best choice. However, in areas with a mild, less hot climate, it’s the opposite. Such locations are ideal for maximizing the effectiveness of this type of housing.

However, as mentioned earlier, due to safety considerations, this type of housing requires regular maintenance and periodic repairs throughout its use. Therefore, it’s crucial to implement the best solutions for safety, including the installation of fire prevention and control systems, to ensure maximum safety during occupancy.

Learn more: What is gusset plate? Features, uses, dimensions and price

Above are the pieces of information that help answer all questions about prefabricated steel buildings, a fairly common and popular construction method nowadays. If you also have construction needs or want to explore more about beautiful prefabricated steel building designs, you can contact Stavian Industrial Metal for the most detailed advice and support.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com