Discover a thorough overview of SAE 1006 steel, including its specifications, similar materials, and various applications. Learn about the essential parameters that define the qualities and composition of SAE 1006 steel. Investigate its versatility and the corresponding materials that can be utilized as substitutes. Discover the various applications for SAE 1006 steel, including automotive components, construction, and general fabrication. This overview is a great resource for engineers, manufacturers, and industry experts who want to know about SAE 1006 steel‘s chemical composition, mechanical qualities, or just grasp its potential.

SAE 1006 is a typical carbon steel grade in the SAE-AISI system. It is a low carbon steel having a nominal carbon content of 0.06%. The “SAE” in SAE 1006 stands for the Society of Automotive Engineers, while “1006” refers to the steel grade in the SAE-AISI system.

SAE 1006 steel is widely used in applications requiring good formability and weldability. It is commonly used in the manufacture of wire rods, wire products, and other cold-formed steel products. Because of its low carbon content, SAE 1006 steel is highly ductile and may be easily molded and formed using methods such as cold drawing, bending, and stamping.

SAE 1006 steel is widely utilized in industries that benefit from its formability and adaptability, including automotive, construction, appliances, and general fabrication.

SAE 1006 Hot Rolled Coil

These specifications provide detailed information about the chemical composition, physical properties, mechanical properties, and thermal properties of SAE 1006 steel. They are essential in determining the suitability of this steel grade for various applications, such as wire manufacturing, cold forming, and general fabrication. It is important to note that these specifications may vary slightly depending on the specific standard or customer requirements. Therefore, referring to the relevant standards or consulting with manufacturers is advised for precise and up-to-date information on SAE 1006 steel specifications.

Regarding material equivalence, SAE 1006 steel is closely related to the following international standards and grades:

ASTM A36 / A36M: ASTM A36 is a commonly used standard specification for carbon structural steel in the United States. It has similar chemical and mechanical qualities to SAE 1006. ASTM A36 steel usually has a carbon content of 0.29% to 0.32%, a manganese concentration of 0.60% to 0.90%, and a maximum sulfur and phosphorus content of 0.050% each.

EN 10111: is a European standard that specifies the specifications for continuous hot-rolled low-carbon steel sheets and strips for cold shaping. The nearest equivalent grade to SAE 1006 in the EN 10111 standard is DD11. DD11 steel’s chemical composition includes a maximum carbon content of 0.12%, a manganese content ranging from 0.60% to 0.90%, and a maximum sulfur and phosphorus content of 0.045%.

JIS G3131: This Japanese standard specifies the criteria for hot-rolled mild steel plates, sheets, and strips. The JIS G3131 standard defines SPHC as the corresponding grade to SAE 1006. SPHC steel has a chemical composition with a maximum carbon percentage of 0.15%, manganese concentration ranging from 0.60% to 1.50%, and maximum sulfur and phosphorus content of 0.050%.

These materials, which include ASTM A36, EN 10111 DD11, and JIS G3131 SPHC, are regarded as equivalent to SAE 1006 because of their identical chemical composition and mechanical qualities. However, it is important to remember that there may be minor differences in specific compositions and qualities, so it is always best to refer to the relevant standards and confer with manufacturers to guarantee the suitable material selection for a given application.

SAE 1006 hot rolled coil is used in a variety of sectors due to its good formability and welding properties. Some common applications of SAE 1006 hot rolled coil are:

SAE 1006 coil is commonly used for cold forming processes such as bending, stamping, and deep drawing. It is widely used in the manufacture of automobile parts such as brackets, reinforcements, and panels, where complex geometries and excellent formability are required.

SAE 1006 hot rolled coil finds use in the building and infrastructure industries. It is used to create reinforcing bars (rebars), which add strength and reinforcement to concrete constructions like buildings, bridges, and roads.

SAE 1006 hot rolled coil is frequently treated using wire drawing processes to produce various types of wires. It is utilized in the manufacture of nails, screws, wire mesh, wire ropes, and other wire-based items.

SAE 1006 coil is used in general fabrication procedures that require low-carbon steel with acceptable formability and welding properties. It can be used to make sheet metal parts, brackets, clamps, hinges, and other components for a wide range of industries.

SAE 1006 hot rolled coil is used to make domestic appliances like refrigerators, washing machines, dryers, and ovens. It is used to create exterior panels, cabinets, and structural components.

SAE 1006 coil is frequently used as a raw material in the construction of pipes and tubes. It is easily molded and welded, making it ideal for creating cylindrical structures for plumbing, structural purposes, and fluid transportation.

SAE 1006 coil is used to manufacture furniture and shelving items. It can be shaped into a variety of forms and sizes to make frames, supports, and brackets.

These detailed applications demonstrate the adaptability of SAE 1006 hot rolled coil in a variety of industries, including automotive, construction, manufacturing, consumer goods, and general fabrication. Its outstanding formability, weldability, and moderate strength make it an ideal choice for a variety of applications that require low-carbon steel with exceptional workability.

SS400 and SAE 1006 are two distinct steel grades with unique properties and applications. Here are the main distinctions between SS400 and SAE 1006:

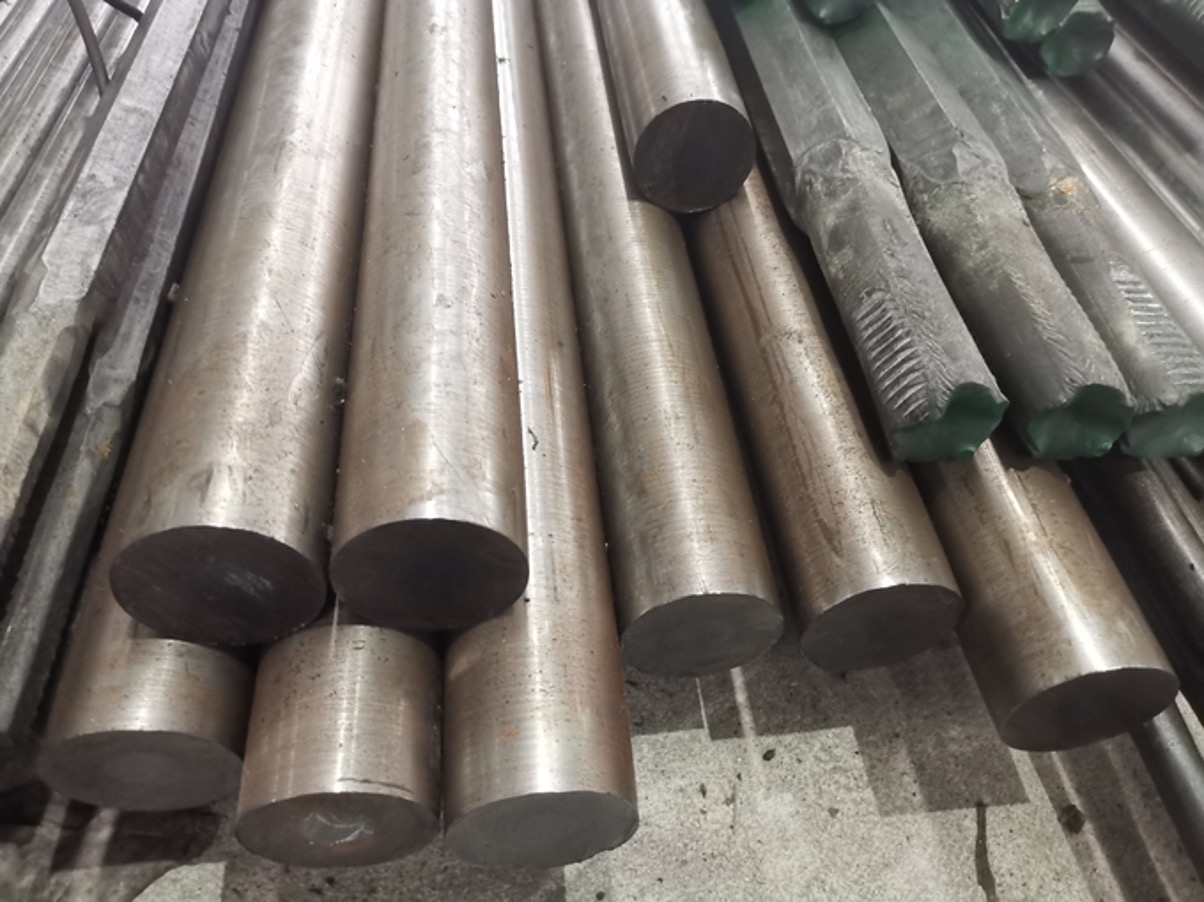

SS400 Steel Bars

It is crucial to note that the specifications and applications described are only basic recommendations; the actual use of SS400 and SAE 1006 may differ depending on individual industry standards and customer requirements. To obtain precise and up-to-date information, consult the applicable standards or manufacturers.

Finally, SAE 1006 steel demonstrates its versatility and vast application in a variety of industries. This analysis has shed light on its specifications, equivalent materials, and uses, providing significant insights for engineers and manufacturers. SAE 1006 steel‘s specific composition and mechanical qualities allow for exceptional formability, making it ideal for cold-forming procedures and the fabrication of complicated components. Its applications include the automotive, construction, general fabrication, and wire drawing industries.

Understanding the specs and applications of SAE 1006 steel allows engineers and industry professionals to make more informed decisions when selecting materials for specific projects. Whether you are looking for low-carbon steel with good workability or alternatives to SAE 1006, this overview provides a thorough understanding of its properties and prospective substitutes. Manufacturers can use the qualities of SAE 1006 steel to build high-quality products that satisfy the needs of a wide range of applications. Its widespread availability and low cost make it popular in the business. Overall, SAE 1006 steel provides a dependable and efficient option for a variety of manufacturing requirements.

Learn more

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com