This tutorial provides a comprehensive introduction to Prepainted Galvanized Steel (PPGI). Learn all about PPGI steel, including its applications, benefits, and manufacturing methods. Learn why PPGI steel is a popular material for roofing, cladding, appliances, and more. Find out about its corrosion resistance, durability, and design versatility. Explore the benefits of pre-painted coatings and how they improve the aesthetics of many businesses. Whether you’re a buyer or just curious about PPGI steel, this article offers valuable insights and considerations. Stay informed and make sound decisions when using Prepainted Galvanized Steel (PPGI) in your projects.

The acronym PPGI steel full form is Prepainted Galvanized Iron (or Steel). It is a sort of pre-painted steel product made out of a base metal, typically galvanized steel, that has been painted or coated with a protective layer. The galvanized steel substrate is highly corrosion resistant, while the paint or coating gives aesthetic appeal and extra protection to the underlying steel. PPGI is commonly utilized in a variety of industries, including construction, automotive, appliances, and furniture, due to its durability, adaptability, and ability to tolerate extreme climatic conditions. It comes in a variety of colors and finishes, providing for customisation and design versatility across multiple applications.

PPGI (Prepainted Galvanized Iron/Steel) coil has several characteristics and properties that make it a popular choice in various industries. Here are some key characteristics and properties of PPGI steel coil:

Substrate Material: The substrate material of the PPGI steel coil is typically galvanized steel, which has a layer of zinc applied to its surface. This galvanized coating provides excellent corrosion resistance to the underlying steel.

Coating Systems: The PPGI steel coil is coated with a protective layer of paint or a combination of resin and other additives. The coating systems can vary and may include polyester, polyurethane, epoxy, or a combination of these materials. These coatings enhance the durability and aesthetic appeal of the steel coil.

Thickness and Width: The PPGI steel coil is available in various thicknesses, typically ranging from 0.12mm to 1.5mm, and widths ranging from 600mm to 1500mm. The specific thickness and width depend on the application and customer requirements.

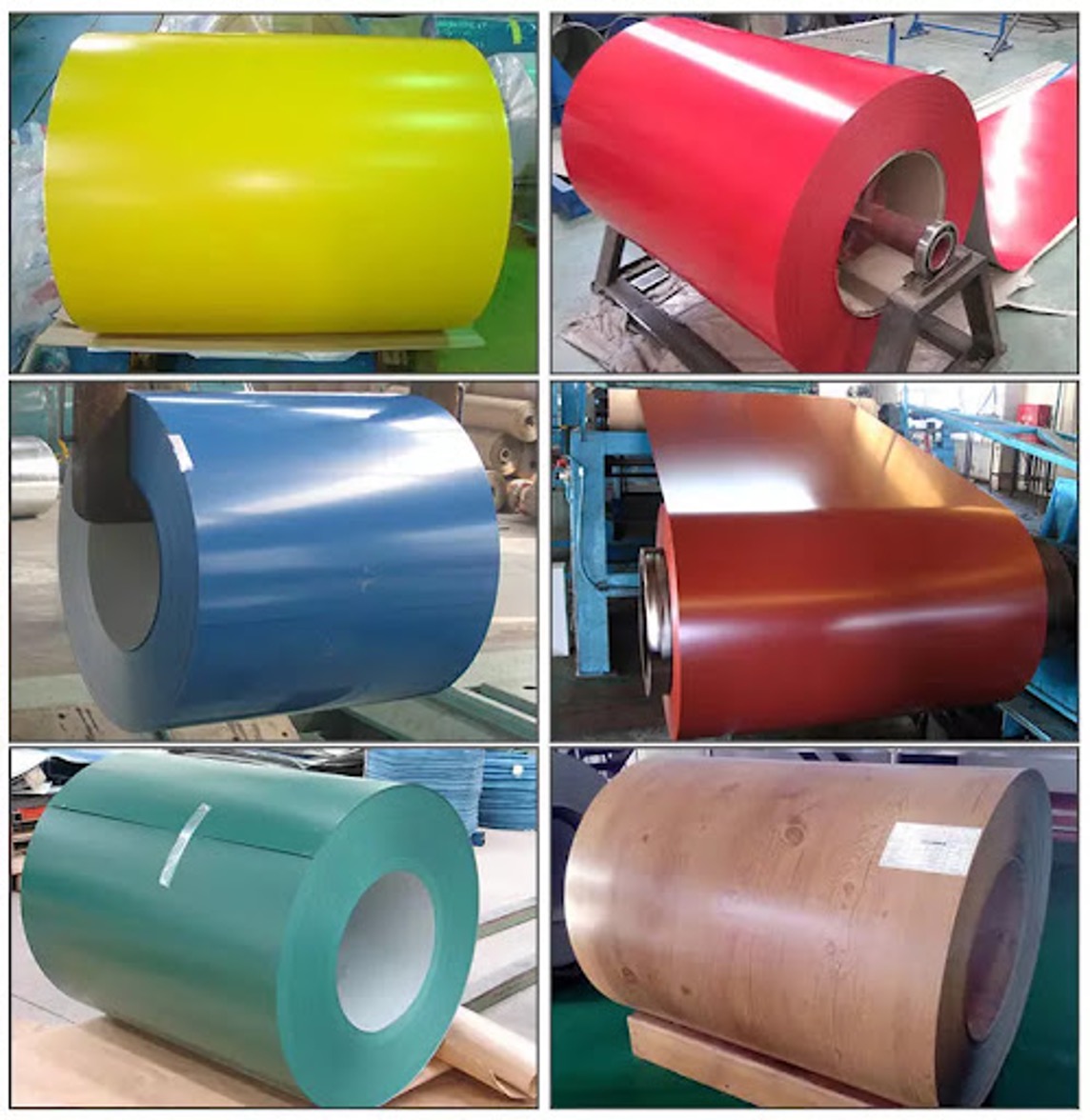

Color and Finish Options: PPGI steel coils offer a wide range of color options, allowing for customization and design flexibility. The coatings can be applied in solid colors, metallic finishes, or even patterns, providing versatility in achieving desired aesthetics.

Scratch Resistance: PPGI steel coils are designed to have good scratch resistance, ensuring that the painted surface maintains its appearance during handling, transportation, and installation.

Flexibility and Formability: PPGI steel coils are highly flexible and can be easily formed, bent, and shaped without cracking or compromising the integrity of the coating. This makes them suitable for various manufacturing processes and applications where complex shapes are required.

Weatherability: The PPGI steel coil exhibits excellent weather resistance, making it suitable for outdoor applications. It can withstand exposure to sunlight, rain, and other environmental elements without significant degradation or color fading.

Chemical Resistance: PPGI steel coils have good chemical resistance, protecting the underlying steel from damage caused by exposure to chemicals, pollutants, and industrial atmospheres.

Easy Maintenance: The PPGI steel coil requires minimal maintenance. It can be easily cleaned with mild detergents or water, and periodic inspections ensure any necessary touch-ups or repairs can be carried out promptly.

Longevity: The PPGI steel coil has a long service life due to its durable coatings and corrosion-resistant substrate. It provides reliable protection to the underlying steel, ensuring the longevity of the coated product.

The PPGI steel coil is widely used in construction, automotive, appliances, and other industries where a combination of aesthetics, corrosion resistance, and durability is required. It offers a cost-effective solution for achieving attractive and functional finished products.

According to Global Import data, 27 World Importers imported Ppgi steel coils from 14 Vietnam Suppliers, totaling 198 shipments.

World obtains the majority of its Ppgi steel coils from India, China, and Vietnam.

India is the largest importer of Ppgi steel coils, with 569 shipments, followed by Poland with 372 shipments, and Pakistan in third place with 329.

The top three product categories of Ppgi steel coils imported from Vietnam has hs code for Ppgi steel coils which are: 72107000, 72107090, and 72109090 respectively.

PPGI steel’s versatility allows for a wide range of applications. Here are some common applications for PPGI steel:

PPGI steel is widely used for roofing and cladding in residential, commercial, and industrial structures. The pre-painted surface is visually appealing, weatherproof, and corrosion-resistant.

PPGI steel is used to make wall panels and siding in construction projects. It provides durability, design flexibility, and color possibilities to improve the aesthetics of structures.

PPGI steel is used in the automotive industry for components like body panels, doors, and trims. The pre-painted coating provides a stylish finish while also protecting against environmental influences.

PPGI steel is utilized in the manufacture of furniture, cabinets, and interior ornamental panels. It comes in a variety of hues and finishes to fit different design styles.

PPGI steel is used in the manufacture of electrical enclosures and cabinets. The pre-painted coating ensures durability and corrosion resistance in a variety of indoor and outdoor electrical applications.

Outdoor signs and advertisement boards are made of PPGI steel due to its weather durability and ability to retain brilliant colors for an extended period of time.

PPGI steel is utilized in grain silos, storage tanks, and machinery. The pre-painted surface protects against rust and extends the life of the equipment.

Refrigerators, ovens, washing machines, and air conditioning units are all made from PPGI steel. The pre-painted surface gives the appliances a sleek and modern appeal.

These are just a few examples of the numerous applications for PPGI steel. Its combination of galvanized steel strength and the advantages of a pre-painted coating makes it a popular choice in a wide range of sectors.

To summarize, this detailed overview has supplied critical information on Prepainted Galvanized Steel (PPGI). We investigated the numerous applications of PPGI steel, which ranged from roofing and cladding to appliances and automobile components. The pre-painted coating not only improves appearances, but also provides corrosion resistance and longevity. Understanding the manufacturing process and benefits of PPGI steel lets you make more informed decisions about which steel to use for your projects. Whether you work in building, manufacturing, or design, PPGI steel provides a versatile solution because of its design freedom and protective characteristics. Stay ahead of the competition by taking advantage of Prepainted Galvanized Steel in your next enterprise.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com