Discover I-beam characteristics, size, and uses in building projects. Learn about I-beam‘s great strength, load-bearing capability, and structural diversity. Investigate their efficient material utilization, compatibility with other building materials, and widespread availability. Discover how I-beams are utilized in construction, bridges, and industrial constructions, among other applications. Discover how they are used in mezzanine flooring, roof support systems, and overhead cranes. Learn about the architectural and structural applications of I-beams. This detailed book is useful for learning the significance and applications of I-beams in a variety of construction projects.

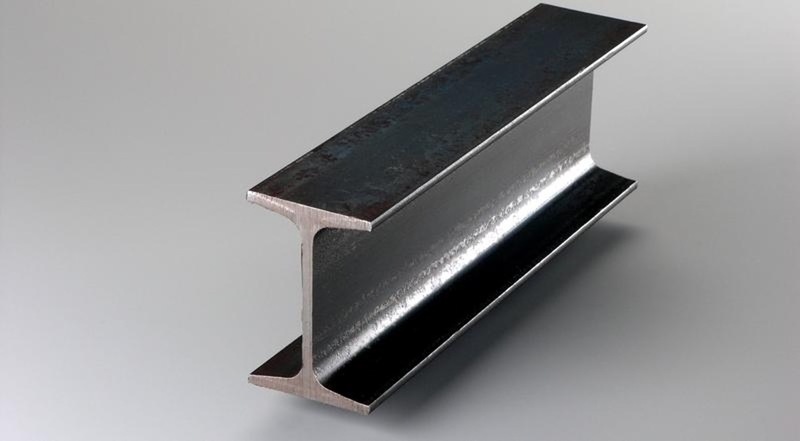

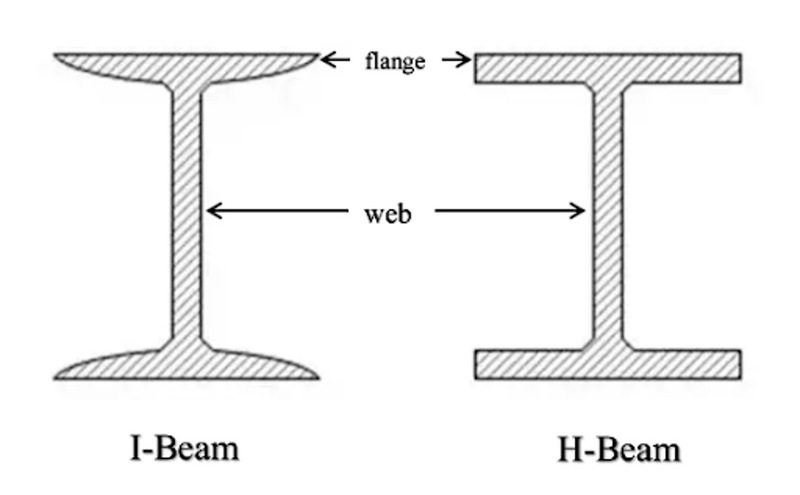

The two most prevalent forms of structural steel beams used in building and engineering are H-beams and I-beams. While both beams are comparable, they have different cross-sectional forms.

H-beams, also known as wide-flange beams, have a form similar to the letter “H.” It consists of two horizontal flanges joined by a vertical web. The flanges are broader than those of an I-beam, resulting in increased load bearing capability and stability. H-beams are noted for their high strength and adaptability, making them ideal for sustaining heavy loads in a variety of applications.

I-beams, also known as I-sections or universal beams, have a cross-section that resembles the letter “I.” It is made up of horizontal top and bottom flanges joined by a vertical web. I-beams are known for their excellent strength-to-weight ratio and efficient load-bearing capacities. They are commonly employed in structural applications that require high strength and stability.

Both H and I beams have unique benefits and applications. H-beams are frequently used for heavy-duty construction projects, such as bridges and high-rise buildings, that require strong support. I-beams are widely utilized in residential and commercial construction, as well as small-scale projects requiring effective load distribution.

The decision between H-beam and I-beam is influenced by project-specific structural requirements, load-bearing capacity, and design considerations. Consulting with a structural engineer or construction professional can assist in determining the best beam type for a certain application.

I-beams are commonly identifiable by their nomenclature, which includes the letter “W” followed by a number. The number shows the beam’s nominal depth in inches. An I-beam’s dimensions also include its flange width (measured horizontally) and web thickness (measured vertically).

Consider the standard W10x30 I-beam:

Depth (web height): 10″

Flange width: 5.75 inches.

Web thickness: Typically around 0.43 inches.

The weight per linear foot of the W10x30 I-beam is roughly 30 pounds.

It’s vital to note that I-beam dimensions and weight can differ depending on regional norms and manufacturer profiles. There are also metric designations for I-beams, such as the “HE” series (HEA, HEB, HEM), which use a slightly different size method based on metric measures.

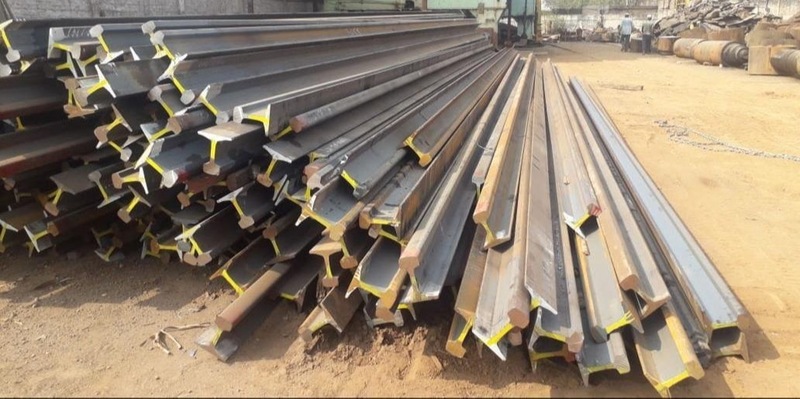

I-beams come in a variety of sizes and dimensions to meet different load-bearing needs and structural designs. While i-beam sizes can vary depending on regional standards and manufacturer, there are some commonly used standard sizes of i-beam. Here are some examples:

These are only a few standard sizes of i-beam; there are many more options available. When deciding on an I-beam size for a specific application, reference structural engineering resources, local norms, or a certified professional to assure sufficient load-bearing capability and structural integrity.

I-beam steel has various distinguishing characteristics that make it a popular and commonly utilized structural component in the building sector. Here are a few of its distinctive characteristics:

I-beam steel is noted for its high strength and load-bearing capacity. Its structural design, which includes a wide flange and a narrow web, enables it to easily carry heavy loads while resisting bending and shearing forces.

Steel I-beam has a high strength-to-weight ratio, allowing it to carry heavy loads while using relatively little material. This efficiency in material consumption leads to cost savings and more sustainable construction techniques.

I-beam steel comes in a variety of widths and diameters, allowing for flexibility in design and construction. It can be utilized for a variety of purposes, including building frames, bridges, industrial buildings, and even smaller-scale projects like home construction.

Because of its inherent strength and stiffness, I-beam steel is ideal for applications requiring long spans without intermediate supports. It enables the development of open and flexible interior spaces in buildings while avoiding the requirement for extra columns or supports.

I-beam steel has exceptional structural stability, with minimal deflection and deformation under high loads. Its large flanges and compact web design make it resistant to bending, torsion, and vibrations, maintaining the structure’s overall stability and integrity.

I-beam steel is compatible with a variety of construction materials, including concrete, wood, and composites. This interoperability enables easy integration with other building components, which speeds up the construction process and provides for more flexible design possibilities.

I-beam steel has become an industry standard and is commonly used in construction. It is made in accordance with defined standards and goes through quality control procedures to ensure consistent and dependable operation.

Overall, the outstanding properties of I-beam steel, such as its high strength, efficient material usage, versatility, long span capabilities, structural stability, compatibility with other materials, and established industry standard, contribute to its importance and widespread use in construction projects of varying scales and complexities.

Steel I-beams are used in a variety of building projects that require structural strength, load bearing capability, and diversity. Here are some frequent uses of steel I-beams:

Steel I-beams are commonly utilized in building construction to provide structural support. They are used to produce beams, columns, and roof trusses, which provide a strong foundation for residential, commercial, and industrial buildings.

Steel I-beams are a popular bridge construction material due to their great strength and ability to span long distances. They are used to make bridge girders, which provide support and stability for both automotive and pedestrian bridges.

Steel I-beams are commonly used in the construction of industrial structures like warehouses, factories, and manufacturing plants. They offer the structural underpinning required to sustain large machinery, equipment, and storage systems.

Mezzanine levels, which are intermediary floors located between major floors, frequently require structural support. Steel I-beams are often utilized to provide a solid and strong basis for mezzanine floors in commercial and industrial structures.

Roof support systems use steel I-beams to carry the weight of the roof structure and distribute it uniformly across the supporting columns or walls. They add structural integrity and stability to roofing systems, particularly in large-scale buildings.

Overhead cranes are supported with steel I-beams in industrial environments. They provide a sturdy and stable foundation for the crane system, allowing for the efficient transfer of big cargoes around the facility.

Steel I-beams are used extensively in infrastructure projects such as tunnels, railway tracks, and airport terminals. They provide structural support for large-scale projects, assuring stability and safety.

Architectural applications include the creation of distinctive and visually interesting designs using steel I-beams. They can be exposed as part of the building’s architecture, lending an industrial or modern feel to the overall architectural concept.

An I-beam clamp, also known as a beam clamp or beam hanger, is a piece of hardware that attaches or suspends objects to an I-beam or steel beam. It offers a secure and customizable connection that eliminates the need for drilling or welding. Here are some important characteristics and applications of I-beam clamps:

Design: I-beam clamps typically have a robust body that may be tightened or secured around an I-beam’s flanges. They frequently use a threaded bolt or screw mechanism for adjustment and tightening.

Load Capacity: I-beam clamps are designed to have a specified load capacity, which is the maximum weight or load that they can safely support. It is critical to choose a clamp that meets the specified load requirements.

Adjustability: Beam clamps often include an adjustable mechanism that enables for exact positioning and alignment on the beam. This adaptability allows you to attach or suspend objects at the desired heights or angles.

Hanging Equipment: I-beam clamps are widely used to hang or suspend equipment, fixtures, and utilities from overhead I-beams. This comprises lighting fixtures, cable trays, conduit, HVAC equipment, signage, and audio-visual systems.

Rigging and Lifting: I-beam clamps are used in rigging and hoisting operations. They provide a secure attachment point for hoists, chain blocks, pulleys, and lifting slings, allowing big goods to be safely lifted and moved.

Support Structures: I-beam clamps can be used to form support structures for temporary installations or building projects. They are used to provide strong connections for scaffolding, temporary platforms, safety barriers, and other temporary structures.

Pipe and Conduit Support: I-beam clamps are used in plumbing and electrical installations to secure pipes, conduits, and ductwork to overhead beams. They provide a dependable attachment point, providing the proper support and alignment of various components.

Stage & Entertainment Rigging: I-beam clamps are commonly used in the stage and entertainment industries for rigging. They allow for the suspension of lighting fixtures, sound equipment, curtains, and other stage elements from overhead I-beams in theaters, concert halls, and event spaces.

It’s important to remember that when using I-beam clamps, you must follow the manufacturer’s instructions and not exceed the load capacity. Furthermore, professional experience and adherence to applicable safety requirements are required to ensure the safe and proper installation of I-beam clamps in a variety of applications.

Installing a steel I-beam typically costs roughly $3.200, but I-beam prices can range from $1.350 to $5.100 based on size and location.

In conclusion, I-beams are an important structural component in the building industry, with a variety of features, diameters, and uses. Their high strength-to-weight ratio, effective load distribution, and structural adaptability make them ideal for supporting big loads over long distances. I-beams’ compatibility with different materials promotes its versatility and incorporation into a wide range of construction projects. I-beams are reliable and stable in a variety of scenarios, including building construction, bridges, industrial structures, and architectural applications. Understanding the characteristics, size, and applications of I-beams enables architects, engineers, and construction professionals to take advantage of their unique attributes and build strong and efficient buildings.

EXPLORE MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com