This detailed guide explains the meaning, applications, essential features, and current pricing of HDG steel, often known as hot-dip galvanized steel. Learn about the various applications and advantages of HDG steel, such as its corrosion resistance and durability. Stay up to date on the latest pricing trends so you can make informed decisions about your construction, infrastructure, or industrial projects. With this vital information at your disposal, you can confidently choose and budget for HDG steel, assuring optimal performance and cost-effectiveness in your projects.

HDG stands for Hot-Dip Galvanized steel. It is a type of steel that has undergone a galvanizing process to provide corrosion protection. HDG steel is widely used in various industries and applications where corrosion resistance is crucial.

The hot-dip galvanizing process involves immersing steel into a bath of molten zinc at temperatures around 450 degrees Celsius (850 degrees Fahrenheit). During this process, the steel is thoroughly cleaned to remove any impurities, such as dirt, oil, or rust, from its surface. The cleaned steel is then immersed in the molten zinc, allowing a metallurgical reaction to occur between the zinc and the iron in the steel.

As a result of the reaction, a layer of zinc-iron alloy compounds is formed on the surface of the steel. The outermost layer consists of pure zinc, providing a protective barrier against corrosion. This zinc coating adheres tightly to the steel, forming a durable and long-lasting barrier that prevents moisture, oxygen, and other corrosive elements from reaching the steel surface.

HDG steel offers several advantages:

Corrosion Resistance: The zinc coating provides excellent corrosion protection to the underlying steel, significantly extending its lifespan. HDG steel is commonly used in outdoor and harsh environments where corrosion can be a significant concern.

Durability: The thick and tightly bonded zinc coating provides mechanical protection to the steel, making it more resistant to scratches, abrasion, and impact. This enhances the overall durability and longevity of the steel.

Self-Healing Properties: If the zinc coating is scratched or damaged, the zinc sacrificially reacts with the corrosive elements in the environment to form a protective layer. This self-healing mechanism helps prevent further corrosion and maintains the integrity of the coating.

Versatility: HDG steel is used in a wide range of applications across various industries, including construction, automotive, infrastructure, agriculture, and more. It is commonly used for structural components, roofing and cladding, fences, guardrails, electrical conduits, and other applications where corrosion resistance is required.

Sustainability: HDG steel is considered environmentally friendly and sustainable. The zinc used for galvanizing is a natural and abundant resource, and the process itself has minimal impact on the environment. Additionally, HDG steel is 100% recyclable, and the zinc coating can be reused or recycled without loss of quality.

Overall, HDG steel is a popular choice for applications that require excellent corrosion resistance, durability, and mechanical protection. Its versatility and sustainability make it a reliable option in various industries.

The structural configuration of HDG (Hot-Dip Galvanized) steel can vary depending on the specific application and design requirements. HDG steel structures can be designed in various configurations to meet the needs of different construction projects. Here are some common structural configurations used in HDG steel:

Beams and Columns: HDG steel structures often utilize beams and columns as primary load-bearing members. These structural elements provide support and transfer loads throughout the structure. Beams are typically horizontal members that span between columns, while columns are vertical members that provide vertical support.

Trusses: Trusses are rigid frameworks composed of interconnected beams and/or columns. They are often used to span large distances and carry heavy loads. HDG steel trusses are commonly employed in roof structures, bridges, and industrial buildings.

Bracing Systems: Bracing systems are used to provide stability and resist lateral loads in HDG steel structures. Bracing can be achieved through diagonal members, cross-bracing, or other configurations. Bracing elements are typically designed to withstand tension and compression forces.

Frames: HDG steel frames are used to create rigid structures that can withstand vertical and horizontal loads. Frames can be simple or complex, consisting of beams, columns, and bracing elements. They are commonly used in building construction, such as in the construction of steel-framed buildings.

Arch Structures: Arch structures utilize curved elements to distribute loads and provide structural stability. They can be found in bridges, roofs, and other applications where a curved design is desired. HDG steel arch structures offer strength, durability, and aesthetic appeal.

Space Frames: Space frames are three-dimensional structural systems composed of interconnected beams, columns, and nodes. They are lightweight, efficient, and can span large areas. HDG steel space frames are often used in stadiums, exhibition halls, and other large-scale structures.

Composite Structures: HDG steel can also be combined with other materials to create composite structures. Composite structures use the strengths of different materials to optimize performance. For example, HDG steel can be combined with concrete to create composite beams or columns.

These are just some examples of the structural configurations that can be achieved using HDG steel. The specific configuration will depend on factors such as the intended use, load requirements, architectural design, and engineering considerations of the project. Professional engineers and designers work together to determine the most suitable structural configuration for each application.

HDG (Hot-Dip Galvanized) steel plates, grating, and angles are commonly used components in the structural configuration of HDG steel. Here’s how these elements can be incorporated into HDG steel structures:

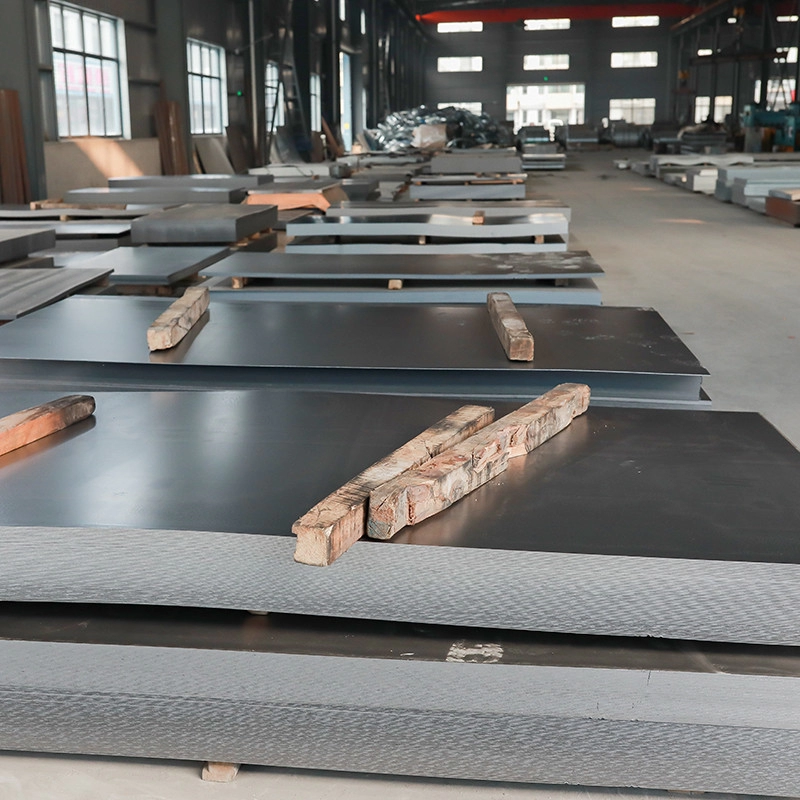

HDG steel plates are flat, rectangular components that can be used in various structural applications. They are often employed as base plates, floor plates, or wall panels in buildings and other structures. HDG steel plates provide a durable and corrosion-resistant surface for load distribution and support. They can be welded or bolted to other steel components to create structural connections.

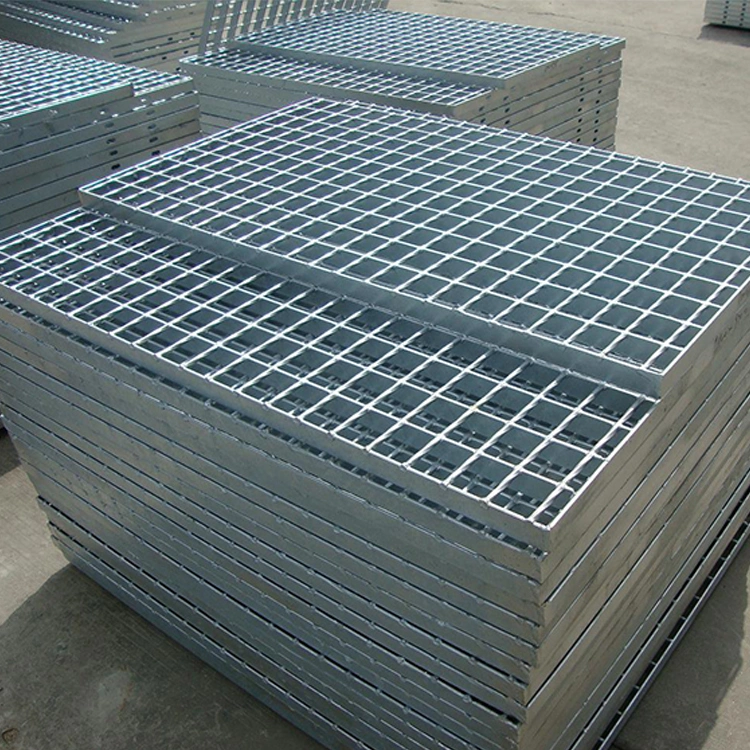

HDG steel grating consists of a series of parallel and perpendicular steel bars welded together to form a grid-like pattern. It is commonly used for flooring, walkways, platforms, and stair treads in industrial, commercial, and infrastructure projects. HDG steel grating provides a strong and slip-resistant surface while allowing for the drainage of liquids and debris. It is often secured to steel beams or frames using clips or other fastening methods.

HDG steel angles are L-shaped structural components with equal or unequal legs. They are used to provide strength, support, and stability in various applications. HDG steel angles can be used as structural members, bracing elements, or connectors in steel frames, trusses, and other structures. They are often bolted or welded to other steel components to create connections and reinforce the structure.

By incorporating HDG steel plates, grating, and angles into the structural configuration, the overall HDG steel structure benefits from enhanced corrosion resistance, durability, and strength. The hot-dip galvanized coating on these components provides a protective layer that helps prevent corrosion and extends the lifespan of the structure. Additionally, the versatility of these elements allows for flexibility in design and construction, enabling the creation of robust and long-lasting HDG steel structures.

Integrated mills in Northern Europe offered €900-920 ($980-1,002) per tonne for CRC and HDG. According to reports, the earliest lead time for both products is April-May. However, buyers estimated realistic prices for CRC at €820-830 per tonne ex-works and for HDG at €830-840 per tonne ex-works.

Southern European producers were looking for €870-880 per tonne delivered (€855-865 per tonne ex-works) for CRC and €900-920 per tonne delivered (€885-905 per tonne ex-works) for HDG. Meanwhile, buyers assessed tradeable prices for CRC at €840-850 per tonne supplied and for HDG at €850-860 per tonne delivered, respectively.

Finally, Vietnamese companies were reported to be aiming for $900-930 per tonne CFR for 0.5mm HDG coated with Z100-120.

To summarize, HDG steel, or hot-dip galvanized steel, has numerous advantages and applications. It refers to the hot-dip galvanizing process, which gives greater corrosion resistance and durability. This makes HDG steel appropriate for a variety of industries, including building, infrastructure, and industrial operations. Longevity, strength, and cost-effectiveness are key factors that contribute to its appeal. To make sound decisions, you must stay up to date on the newest pricing changes. Understanding the meaning, applications, major qualities, and pricing dynamics of HDG steel allows you to confidently choose the best material for your unique requirements, resulting in long-lasting and cost-effective solutions.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com