Galvanized steel is a corrosion-resistant material that protects critical surfaces in the industrial and construction sectors. With its variety of sizes and shapes, galvanized steel withstands harsh weather conditions well. Widely used in construction and mechanical manufacturing, galvanized steel plays an important role in contributing to the stable development of many industries.

Galvanized steel, also known as zinc-coated steel or cold-rolled steel with zinc coating, consists of steel sheets covered by a layer of zinc based on hot-dip galvanizing principles. With its shielding function, it provides excellent protection under harsh environmental conditions. It is one of the most popular materials used in the construction and civil industries, such as electrical equipment frames, household appliances, machine casings, etc.

According to research, galvanized steel sheets are produced from cold-rolled steel coated with zinc. They undergo four stages as follows:

Galvanized steel products are widely used in practice. There are various types of galvanized steel sheets with the following standards:

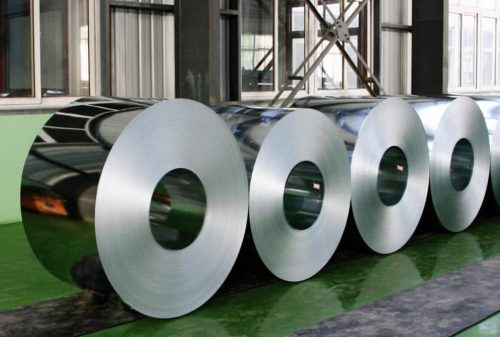

First, let’s look at galvanized steel coils. These coils have a smooth, shiny surface with extremely good corrosion resistance. They are applied in the production of processed goods, handicrafts, or rolling. The general technical specifications for this type of steel are:

Next, let’s explore corrugated galvanized steel sheets. These are galvanized steel sheets rolled into corrugated patterns, available in various shapes and sizes. The general standards for this type of steel are:

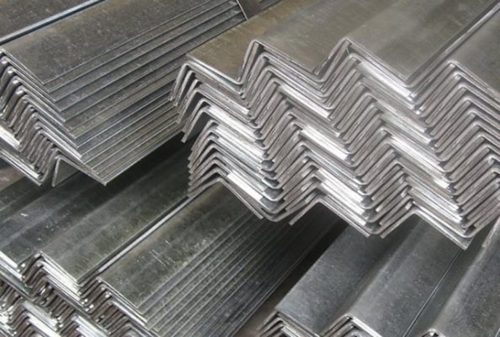

Galvanized steel sheets are steel sheets with an added layer of zinc coating. They have varying zinc thickness per product. These sheets are very hard, making them suitable for making products with high protection and shielding. The hardness of the sheet depends on the type of steel used for galvanization. The general standards for galvanized steel sheets are:

When it comes to galvanized steel products, their applications are diverse in many fields such as:

Additional References

Stavian Industrial Metal Corporation is known for being a reliable and quality provider of industrial metal materials. When you choose Stavian, you can be completely assured of prompt and timely service. With extensive experience and a wide range of products, Stavian can easily meet all your needs, from small-scale projects to large-scale constructions. To inquire further, simply contact us through the channels provided below, and our dedicated staff will assist you with detailed consultation.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com