Bar billets are critical in establishing the quality of building steel lines. So, how are steel bars manufactured? Find out with Stavian in the article below.

A bar billet is a semi-finished product that is used in the production of various metal bars. It is usually a solid, rectangular-shaped piece of metal that is subsequently processed to become a finished bar product.

Bar billets are typically manufactured by a casting process in which molten metal is poured into a mold or continuous casting machine to generate the billet’s initial shape. Following the solidification and cooling of the billet, it is subjected to additional processes such as hot rolling, forging, or extrusion to produce the appropriate dimensions and qualities.

Depending on the exact purpose and needed properties of the final bar product, bar billets are usually manufactured from metals such as steel, aluminum, copper, or brass. They are frequently used as feedstock in the manufacture of different long metal products such as round bars, square bars, hexagonal bars, and flat bars.

The size and dimensions of bar billets can vary greatly based on the intended usage and the final bar product specifications. These measurements are normally given by the manufacturer or client and may include length, width, and thickness.

Read more

Steel billet manufacture is a difficult operation that necessitates a high level of professionalism. To generate a high-quality completed construction steel product, the steel billet manufacturing process must be precise and rigorous at all stages. The following steps will be included in the manufacturing process: ore mining, ore smelting, steel rolling, and finally product finishing.

The initial phase in the creation of steel billets is the extraction of ore, which is then transferred to iron and steel production zones. Raw materials will be heated to 1300 degrees Celsius in order to create a hot metal stream. This is accomplished by burning coke and reacting it with oxygen gas to generate the required high temperatures.

Following that, the hot metal stream will be directed to the arc furnace, where impurities in the metal stream will be removed and the chemical composition will be adjusted. The finished product will be steel billet. Steel billets will be created in various thicknesses and diameters, resulting in various forms of milled steel.

The billets are first warmed in a separate furnace, which boosts the temperature of the billet to over 1200º F. The billet retains its shape at this temperature but can be molded. The billets are then accelerated through a series of extrusion presses at speeds of up to 4000 feet per minute, depending on the bar diameter. The faster the bar goes, the narrower the cross section becomes. Multiple presses in a series compress the red hot billets into increasingly longer lengths and smaller diameters while also cooling the material as it moves through the process.

The heated bar is driven through the proper mandrel for the rebar size being produced in that run as it approaches the end of the line of extrusion presses. The mandrel creates the deformations seen on reinforcing steel, which allow the rebar to be mechanically anchored in the concrete. The specific shape of the bar deformations is not required, but the size, spacing, and height are specified in ASTM A615.

The bars are stamped with the required identification marks as the final phases of the manufacturing process are finished. These identifying marks indicate the producing mill, the size of the bar, the type of reinforcing steel used in the bar’s manufacturing, and the steel grade.

The finished bar is delivered in 120-foot lengths from the fabrication facility. After cooling, it is sheared into 60-foot lengths, bundled and labeled, and ready for shipment to fabrication facilities, where the reinforcing steel is cut and bent to comply with the needs of the specific project, as defined by the engineer.

Macroetching is a commonly used process for evaluating steel products such as bars, billets, blooms, and forgings.

This method includes a procedure for assessing steel specimens using a graded sequence of images demonstrating the occurrence of specific circumstances. The approach is only applicable to carbon and low alloy steel bars, billets, blooms, and forgings.

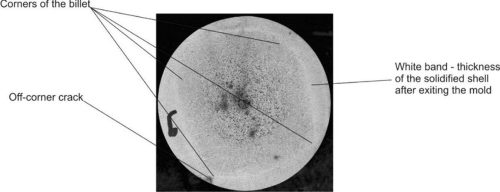

Surface crack (off-corner fracture) in the cross-section of a macro-etched rolled bar

Depending on the sort of inspection to be performed, a variety of etching reagents may be utilized. Steels respond differently to etching reagents due to differences in chemical composition, manufacturing process, heat treatment, and a variety of other factors. It is impracticable to establish generic acceptance or rejection rules for all conditions since some conditions must be examined relevant to the part in which they occur.

The values given in SI units are to be considered standard. The values in parenthesis following SI units are supplied for information only and should not be considered standard.

It should be noted that this standard does not attempt to address all, if any, safety concerns related with its use. Prior to usage, it is the user’s obligation to establish adequate safety, health, and environmental standards and to evaluate the application of regulatory constraints.

This international standard was developed in accordance with internationally recognized standardization principles outlined in the World Trade Organization Technical Barriers to Trade (TBT) Committee’s Decision on Principles for the Development of International Standards, Guides, and Recommendations.

The utility of a bar billet or a bar billet bloom is determined by the unique requirements and applications of the final items being manufactured.

Unlike billet blooms, bar billets are smaller in size. They are often utilized as raw materials for the manufacture of several types of bars, such as round bars, square bars, and hexagonal bars. Bar billets are versatile in that they can be further treated via hot rolling, forging, or other shaping procedures to get the appropriate dimensions and qualities of the finished bar product. They are appropriate for applications requiring standard-sized bars, such as construction, manufacturing, automotive, and other industries.

Billet blooms are larger in size compared to bar billets. They are used as starting materials for larger and heavier bars, rods, or sections. Billet blooms are typically formed by hot rolling, forging, or other shaping procedures to produce the necessary dimensions and qualities. They are in handy when larger and heavier bars or pieces are needed, such as when building massive structures, heavy machinery, or infrastructure projects.

In terms of utility, both bar billets and bar billet blooms have applications and play critical roles in the steel industry. The choice between the two is determined by the final product’s precise size, weight, and intended application.

Bar billets are an important intermediate product in the metalworking sector, serving as the beginning point for the manufacturing of a variety of bars used in construction, equipment, automotive, aerospace, and other industries. The quality and consistency of bar billets have a direct impact on the qualities and performance of the final bars, making them an important aspect in maintaining overall product quality. Thank you for reading!

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com