Aluminum framing is changing the way we think about building structures. By using lightweight yet durable aluminum, this method offers a range of benefits that traditional construction methods can’t match. T-slot aluminum, in particular, is incredibly versatile and is used in a variety of applications, from industrial buildings and greenhouses to homes. One of the key advantages of aluminum framing is its modular design, which makes it easy to assemble, modify, and disassemble. This makes it an ideal choice for temporary structures or buildings that need to be frequently reconfigured. Let’s explore the many reasons why aluminum framing is becoming a go-to option in construction.

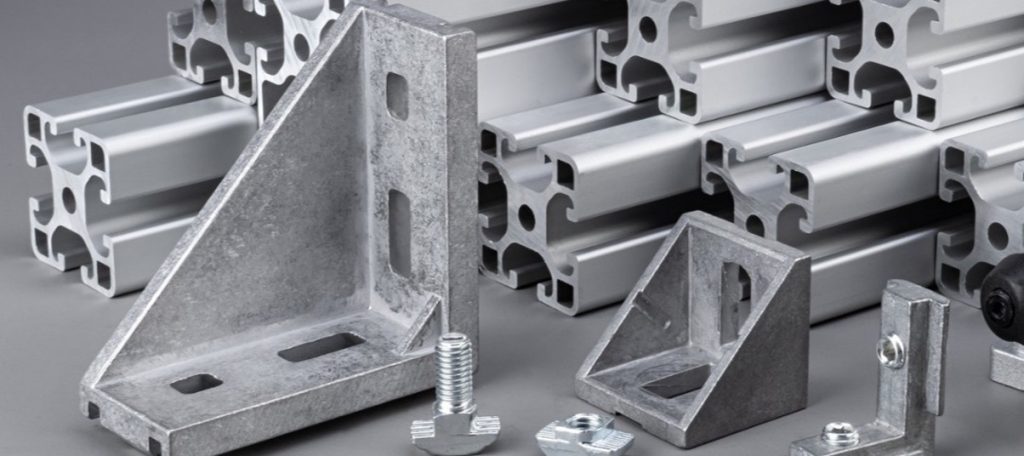

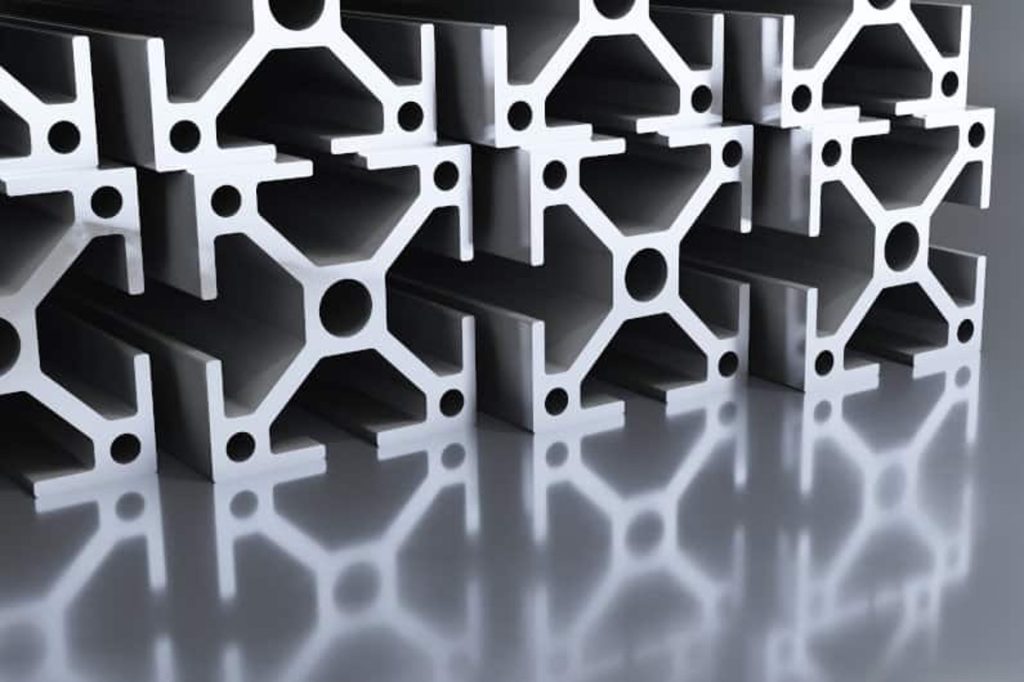

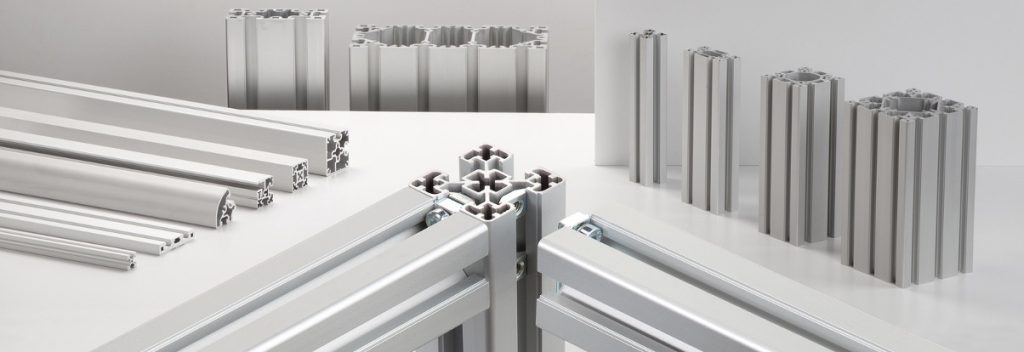

Aluminum framing is a modular system made from extruded aluminum framing profiles. This versatile setup is used to build jigs, machine frames, and various other industrial products. These structural aluminum framing require aluminum framing parts that match the shape of the integrated aluminum profiles. Therefore, selecting the right aluminum framing system involves carefully analyzing product features and the reputation of suppliers.

Now that you know where aluminum framing is used, it’s important to understand its benefits. Some, like durability and longevity, have already been mentioned, but there are many more advantages to consider. Below are the advantages of aluminum framing extrusion:

Aluminum framing is more affordable than many other construction options. Instead of using traditional welded steel, aluminum provides a stronger and cheaper alternative. This allows for quick and budget-friendly construction, saving both time and money. With numerous bolting connectors and hundreds of profiles to choose from, structures can be built easily without special tools.

The cost savings with aluminum framing extrusion go beyond the initial construction. Its modular design facilitates effortless adjustments, expansions, or reconfigurations without incurring substantial costs. This flexibility is especially beneficial for businesses needing to adapt to changing requirements or scale operations quickly.

Aluminum framing is also eco-friendly and reusable, making it simple and cost-effective to adjust structures as needed. The material’s durability reduces the frequency of repairs or replacements, leading to long-term cost savings. Additionally, aluminum is 100% recyclable, making it a sustainable choice for environmentally conscious builders.

This system boosts productivity and employee comfort due to its versatility, allowing for easy customization of workstations. For even more savings, powder-coated aluminum framing looks great and eliminates the need for painting, saving both time and money while providing an extra layer of protection against corrosion and wear.

Aluminum framing can easily be used to build complex structures like buildings, bridges, and industrial properties. This framing system not only supports these large structures but also benefits the people who use them daily.

For example, in manual production setups, aluminum framing extrusion allows for easy reconfiguration. It is sturdy enough to handle numerous changes, which boosts productivity and enhances employee comfort. This adaptability makes aluminum framing an ideal choice for creating efficient and flexible working environments.

Lean manufacturing is a process that streamlines production procedures to ensure customers get exactly what they need. This approach offers several advantages for manufacturers, including increased productivity, reduced inventory, and faster time-to-market for new products.

Lean manufacturing also benefits workers and employers by reducing job-related injuries and boosting worker productivity. By using aluminum framing, implementing lean manufacturing becomes easier, helping to make your business a success story. Aluminum’s flexibility and ease of use allow for quick adjustments and improvements, supporting a lean and efficient production environment.

Aluminum framing demonstrates remarkable versatility across various industries, providing safe and durable structures. Its lightweight yet durable nature allows it to be effectively used in the medical, transport, and construction sectors. Additionally, aluminum framing’s corrosion resistance enhances its longevity, making it a reliable choice for diverse applications.

Custom-built workstations tailored to production needs are safer and more efficient. Aluminum framing offers the modularity required for quick adjustments and improvements.

Opting for powder-coated aluminum framing eliminates the need for painting. Simply connect the profiles together, and the powder coating provides a sleek, attractive finish.

With over 100 aluminum profile designs and sizes available, you can easily bring your design ideas to life. This flexibility ensures that your workstations are not only functional but also aesthetically pleasing.

Aluminum framing comes in various types and sizes that can be tailored to meet specific strength requirements. These framing systems are designed to resist excessive bending, with each profile typically accompanied by a bend analysis to assist in making the right choice for your application. This ensures that your structures are not only strong but also precisely engineered to withstand the demands of their intended use.

Aluminum framing can be powder coated to meet your specific needs. This process saves time since there’s no need for additional painting once construction is complete. Powder coating provides a durable, aesthetically appealing finish with a glossy appearance, enhancing the overall look of your project.

Aluminum is an elemental metal that retains its properties through multiple reuse cycles, making it highly sustainable. Its non-toxic nature also makes it a responsible choice for reducing your business’s carbon footprint. Opting for aluminum framing supports environmentally friendly practices without compromising on durability or performance.

Aluminum framing offers impressive thermal benefits due to its exceptional thermal conductivity. This property allows for efficient heat transfer, which can be optimized with thermal boost technology. By minimizing heat loss during cold weather, aluminum framing helps maintain a warm interior temperature and reduces condensation, thereby enhancing overall thermal performance in buildings.

Due to its lightweight construction and straightforward installation process, aluminum framing demands little maintenance. Unlike other materials, such as steel, aluminum structures often require less demanding assembly processes. For instance, aluminum stairs can be installed without needing a permit, as the support poles can simply be pushed into the ground without a concrete base.

This flexibility allows aluminum structures to be used on various terrains, including rocky or boulder-filled areas, without the need for extensive groundwork. This ease of installation and adaptability make aluminum framing a practical choice for projects where simplicity and efficiency are key

Unlike traditional steel structures that require painting, priming, and welding, aluminum framing offers a swift deployment solution. Aluminum does not require any of these preparatory steps. Additionally, no machining is necessary, yet aluminum remains nearly as robust as steel while being more cost-effective. Assembling aluminum frame structures is also quicker compared to steel, making it an efficient choice for projects requiring fast deployment and cost savings.

Aluminum framing finds wide-ranging applications across various industries due to its lightweight yet durable nature. Here are some key uses in construction structure:

Aluminum framing square is an excellent material for door frames in buildings due to its durability and low maintenance requirements. Its corrosion resistance ensures longevity. Compared to steel, aluminum has a better strength-to-weight ratio and can be alloyed with metals like magnesium, silicon, copper, and manganese to enhance its strength. These alloys can significantly increase aluminum’s tensile strength, making it a robust choice for door frames. Moreover, aluminum maintains its strength even in cold temperatures, unlike metals that may become brittle under similar conditions. Beyond functionality, aluminum door frames offer a sleek appearance that complements modern designs, making them a sturdy and stylish investment for any property.

Windows are crucial components of any building, providing ventilation and natural light that enhance interior comfort. Aluminum framing square is widely used for window frames due to its durability and ability to withstand harsh weather conditions.

Aluminum window frames provide durability and robustness, making them ideal for use in a variety of settings, including industrial, commercial, and residential buildings. They are resistant to cracking and scratching caused by heavy rains, strong winds, and high temperatures.

In addition to their durability, aluminum window frames are cost-effective and require minimal maintenance. They can be customized extensively to suit various architectural styles and preferences. Powder-coated aluminum frames are particularly popular as they provide a wide range of color options while enhancing corrosion resistance. This makes extruded aluminum framing an attractive and practical choice for window installations across different types of buildings.

Railings are essential features in any structure, providing support to prevent slips and acting as barriers for safety. Aluminum railing frames are favored for their durability, safety, and aesthetic appeal.

Aluminum is inherently customizable and flexible, making it ideal for creating railings that meet both functional and design needs. These railings can be powder coated in various colors or combined with glass panels to enhance their visual appeal and match different architectural styles.

In addition to their versatility, aluminum railings require minimal maintenance and offer long-lasting performance, making them a practical choice for both residential and commercial applications where safety and aesthetics are paramount.

Shower enclosures serve a crucial role in dividing bathrooms and preventing water from spreading across the floor. While homeowners have various material options for shower enclosure systems, aluminum framing stands out as the optimal choice for several reasons.

Firstly, aluminum shower enclosure structures offer exceptional durability, effectively containing water within the shower cubicle. This feature not only enhances safety by reducing accidents but also simplifies the cleaning process. Unlike materials like curtains, aluminum frames minimize moisture and soap residue buildup, requiring minimal maintenance.

Choosing aluminum for shower enclosures ensures longevity and functionality, providing a reliable solution for maintaining a dry and safe bathroom environment.

Roof trusses are essential structural components that shape roofs and provide support for ceilings. When constructing roof trusses, it’s crucial to use lightweight materials capable of withstanding pressure effectively, making aluminum framing the ideal choice.

Aluminum framing for roof trusses offers robustness, capable of shielding structures from storms and strong winds while maintaining structural integrity. Unlike wood trusses, which are vulnerable to damage from termites and corrosion, aluminum is resistant to both pests and corrosion. This durability ensures long-term reliability and reduced maintenance, making aluminum framing a superior option for constructing resilient and secure roof trusses.

Aluminum framing finds extensive use in the medical industry, leveraging its lightweight and corrosion-resistant properties. Common medical structures made with aluminum framing include hospital beds, gurneys, storage cabinets, workbenches, and more.

The versatility of aluminum framing makes it indispensable in medical settings, spanning from doctor’s offices to patient wards. Its durability, flexibility, and high customizability contribute to its widespread adoption, ensuring that medical facilities can rely on sturdy and adaptable solutions for their equipment and furniture needs.

Aluminum framing is commonly used in the construction of shipping containers due to its portability and lightweight nature. Manufacturers favor aluminum for shipping containers because it is easy to work with, allowing them to produce multiple containers quickly.

The use of aluminum framing in shipping containers enhances their mobility and durability while maintaining structural integrity. This makes aluminum-framed shipping containers a preferred choice for transporting goods across various distances efficiently and safely.

Aluminum framing is also utilized in the transport industry for constructing bridges, including popular designs like the arch bridge. These bridges feature a variety of aluminum arches connected by beams.

Aluminum framing allows for the rapid construction of sturdy arches, facilitating the swift and safe passage of heavy loads across narrow paths. This construction method leverages aluminum’s lightweight yet durable properties, ensuring bridges are both efficient and resilient in supporting transportation infrastructure.

Aluminum is widely used in shipbuilding for constructing vessels with spacious cargo holds and powerful engines capable of efficient movement through water. Aluminum framing plays a crucial role in ship construction due to its lightweight, durability, and strength, which enable it to withstand the harsh conditions of large waterways.

The use of aluminum framing in shipbuilding facilitates the creation of robust and efficient vessels that combine structural integrity with reduced weight. This makes aluminum-framed ships ideal for achieving optimal performance and reliability in marine environments, ensuring safe and efficient transportation of goods and passengers across oceans and waterways.

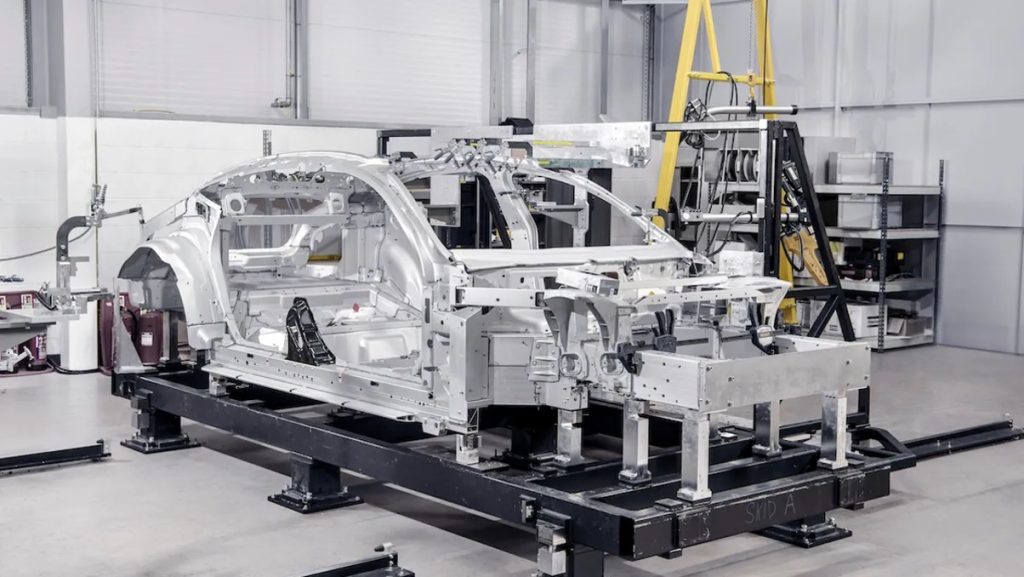

Aluminum framing is extensively used in the manufacturing of various automobiles, including trucks and small vehicles, due to its combination of durability and strength. This allows vehicles to carry heavy loads and navigate both smooth highways and rough terrain effectively.

In automobile manufacturing, aluminum framing is utilized to create essential components such as chassis frames and wheels. These components are critical for vehicle stability and performance, particularly in challenging conditions like muddy or pot-holed roads.

The use of aluminum framing in automobiles contributes to improved fuel efficiency, reduced overall weight, and enhanced durability, making it a preferred material choice for constructing modern vehicles that prioritize both strength and efficiency.

Ensuring the long-term durability of aluminum framing requires regular maintenance. Here are essential tips to keep them in optimal condition:

Following these maintenance practices will help preserve the strength and appearance of aluminum framing, ensuring they remain functional and aesthetically pleasing for years to come.

Aluminum framing systems offer durability, sustainability, and flexibility, making them attractive for construction projects. Examples like t-slot aluminum framing and aluminum deck railings highlight their versatility. However, considerations such as cost and thermal conductivity should be weighed when choosing aluminum framing for construction. Evaluating these factors ensures that aluminum framing meets project needs effectively, providing resilient solutions for modern building challenges.

EXPLORE MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com