Steel square billets play an incredibly significant function in defining the quality of building steel lines, but not everyone understands what they are. What is the purpose of a square billet? What is the price? Continue reading Stavian’s post for more important information.

Read more: What Exactly Is Iron Ore?

Steel billets are manufactured from raw steel and cannot be used in their entirety. It must instead be cast in a different shape before it may be utilized for other purposes. Steel billets are the newly manufactured structural steel, which is still a square-shaped steel bar.

Steel billets are only used when they have been formed into appropriate sizes. It must be processed into more marketable bits before being sold. Once molded into a shape, the raw form of steel, known as steel billets, is employed.

They feature a well-defined grain structure. It allows the metal to be treated indefinitely. The metal is also quite flexible and has a number of properties.

They feature a well-defined grain structure. It allows the metal to be treated indefinitely. The metal is also extremely flexible and elastic. Furthermore, the metal is inexpensive and widely available in most parts of India.

Steel billets are made by liquifying wipe iron, loading it into casting machinery, and cooling it. They are usually turned into final goods like sheets, chunks, bars, or poles at the corporation’s primary processing facility.

They are also sold to a variety of different industries to be rerolled or completed into finished goods. Steel billets are not used as a finished product by an individual buyer, but rather as a raw material in manufacturing activities.

The square billet is a steel box structure that is sturdy and heat resistant. Many major and minor enterprises in industrialized countries such as England and America… This form of steel billet has recently become more widespread in Vietnam.

Manufactured with equal length and width, giving a square shape, as the name suggests. Square Steel Billet is a steel and carbon composite product with high durability and bearing capacity.

Square billets have a square cross-sectional form and diameters ranging from 100 x 100 mm to 150 x 150 mm. The length of a square steel billet is normally between 6 and 12 meters. Hot-rolled steel billets, such as rolled steel and construction steel bars, are made from square billets.

There are numerous applications for steel billets, some main square billet applications are described below.

Read more

Billet steel and aluminum are two prominent machining materials that have distinct advantages in various applications. Do you know which type to select? Your choice will be determined by the type of application for which you require your parts or components, so make sure to evaluate all of the considerations stated below before making your pick!

In terms of strength and longevity, billet steel is by far the superior material. It has a far higher tensile strength than aluminum and is much more resistant to bending or flexing. As a result, it’s an excellent solution for components that will see a lot of wear and tear, such as engine blocks or wheels. However, billet aluminum does not provide as much strength but is still quite robust. It can also be anodised to give further corrosion and wear resistance.

Another significant distinction between billet steel and aluminum is weight. Because billet steel is heavier than aluminum, it takes more energy to move it during machining operations or when transferring finished parts from one area to another. If you’re working with a significant number of parts or components, this can quickly mount up. When considering their individual strengths and weights, both materials are quite equal in terms of cost. However, due to its heavier weight, billet steel may demand more energy than a machine, perhaps resulting in higher long-term expenditures.

One of the primary benefits of billet steel is its tremendous strength and durability. Furthermore, billet steel has a low carbon content, making it resistant to rust and corrosion.

However, one of the primary benefits of billet aluminum is that it is lighter than billet steel, making it easier to work with. Furthermore, billet aluminum has a very high strength-to-weight ratio, making it perfect for applications where weight is an issue.

Due to its extreme hardness, one of the main disadvantages of billet steel is that it can be difficult to deal with. Furthermore, billet steel has a larger carbon content than billet aluminum, making it more prone to rust and corrosion.

However, one of the main disadvantages of billet aluminum is that it can be difficult to weld because of its low melting point. Furthermore, billet aluminum has a lower strength-to-weight ratio than billet steel, making it less suitable for applications where weight is an issue.

Finally, think about attractiveness and corrosion resistance. Both materials can look wonderful aesthetically depending on how they are polished once machining procedures are performed. However, in terms of corrosion resistance, billet steel outperforms aluminum alloys because of its higher tensile strength, making it excellent for outdoor applications where exposure to moisture or other elements may occur over time.

To determine the weight of a steel billet, you must first determine its length, breadth, and thickness, as well as the specific density of the steel utilized.

The weight calculation formula is as follows: Weight = length * thickness * width *density.

For example, if a steel billet is 1 meter long, and 0.1 meter thick, 0.5 meter wide, and its density is 7,850 kg/m3, the weight of the billet is: Weight = 1 * 0.1 * 0.5 * 7,850 = 393.75 kg

It should be noted that density varies based on the type of steel and its composition. If you are unsure about the density of the steel you are working with, you should call the manufacturer or a materials expert.

The standard square billet parameter table is shown below:

| Type & size | 120 x 120mm, 150 x 150 mm |

| Length | 12 m ± 50mm |

| Tolerances

|

Maximum edge deviation: ± 2 mm

Maximum diagonal deviation: ± 6 mm |

| Weight | 1,350 – 2,100 kg |

| Curvature | 100 mm/m, ≤ 80 mm/12 m |

Thus, we can see that a square steel billet with dimensions ranging from 120 x 120 mm to 150 x 150 mm and a length of 12 m will weigh between 1,350 and 2,100 kg.

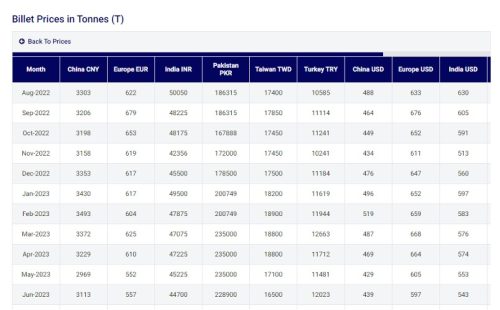

Steel billets are frequently sold or purchased from other countries. Steel billet prices around the world alter and fluctuate in response to the overall circumstances and the influence of numerous factors. According to historical statistics, steel billet in Southeast Asia is mostly sourced from the Commonwealth of Independent States, the Philippines, Indonesia, and Thailand, with prices ranging from 540 to 550 USD/ton (CFR). This pricing can fluctuate depending on the year and time of year.

Meanwhile, the asking price for steel billets manufactured in electromagnetic arc furnaces or blast furnaces in the Middle East, Japan, Taiwan, India, and Vietnam is between 545 and 560 USD/ton (CFR).

Turkey is also one of the world’s major producers of steel billets. Turkish steel billet is frequently shipped to North America, Southeast Asia, and the Middle East, with selling prices ranging from 510 to 520 USD/ton (CFR).

Billet steel and aluminum are two prominent machining materials that have distinct advantages in a variety of applications. While both materials are robust enough for most applications, billet steel has higher tensile strength while being slightly heavier than aluminum, making it appropriate for difficult tasks requiring high durability, such as engine blocks or wheel components. Furthermore, it is more corrosion resistant than aluminum alloy in outdoor applications where moisture exposure may occur over time. On the other hand, aluminum is lighter, allowing for easier transportation and handling during machining operations while still offering appropriate corrosion protection in most cases—making it ideal for interior applications where weight isn’t a problem but cost savings are!

The preceding article defines square billet and aluminum square billet while also providing a summary of domestic and international square billet markets. Changes in the Vietnamese and global markets might have an impact on square billet prices.

Increasing your knowledge and awareness of these elements can thus assist you in better understanding the worldwide square billet market. Thank you for taking the time to read this!

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com