Our complete analysis reveals the versatility and effectiveness of sandwich panels. Discover the advantages, materials, and applications of sandwich panels in modern buildings. Sandwich panels are an excellent investment for your building projects, providing increased energy efficiency as well as durability and strength. Learn about the newest breakthroughs in sandwich panel technology, as well as essential design and installation recommendations. Sandwich panels, with their lightweight yet durable design, are changing the way we build. Unlock the possibilities of sandwich panels and stay ahead of the construction industry’s ever-changing landscape. This strong construction solution will help you enhance your projects.

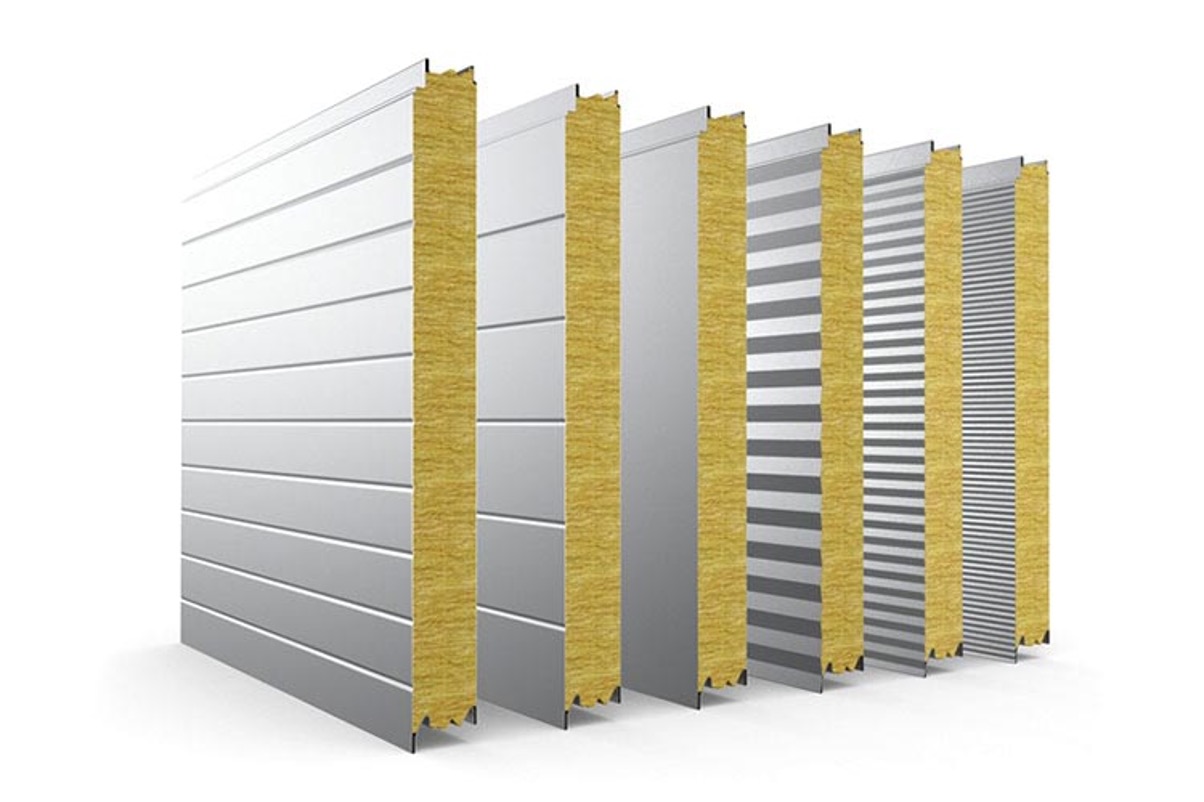

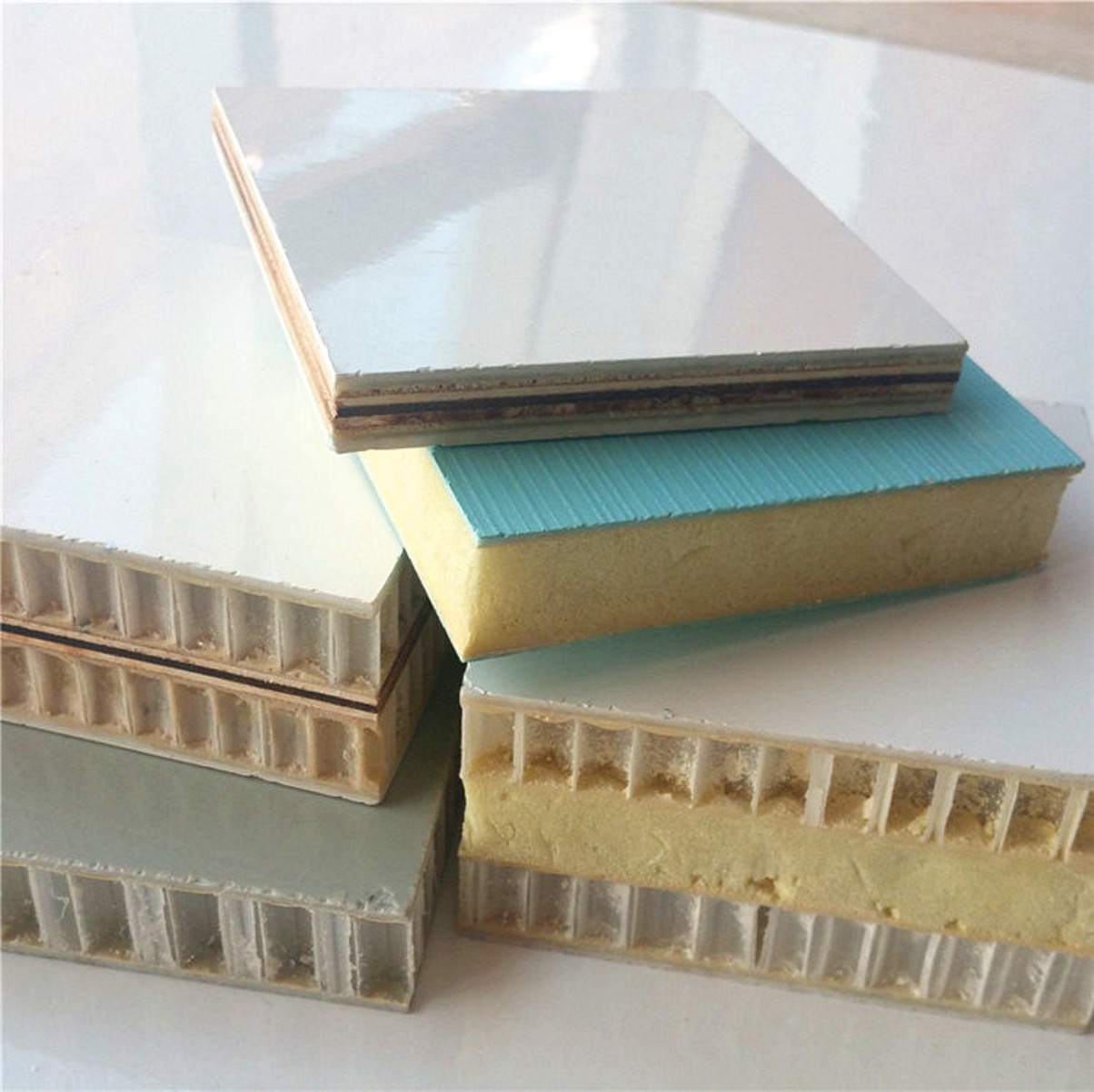

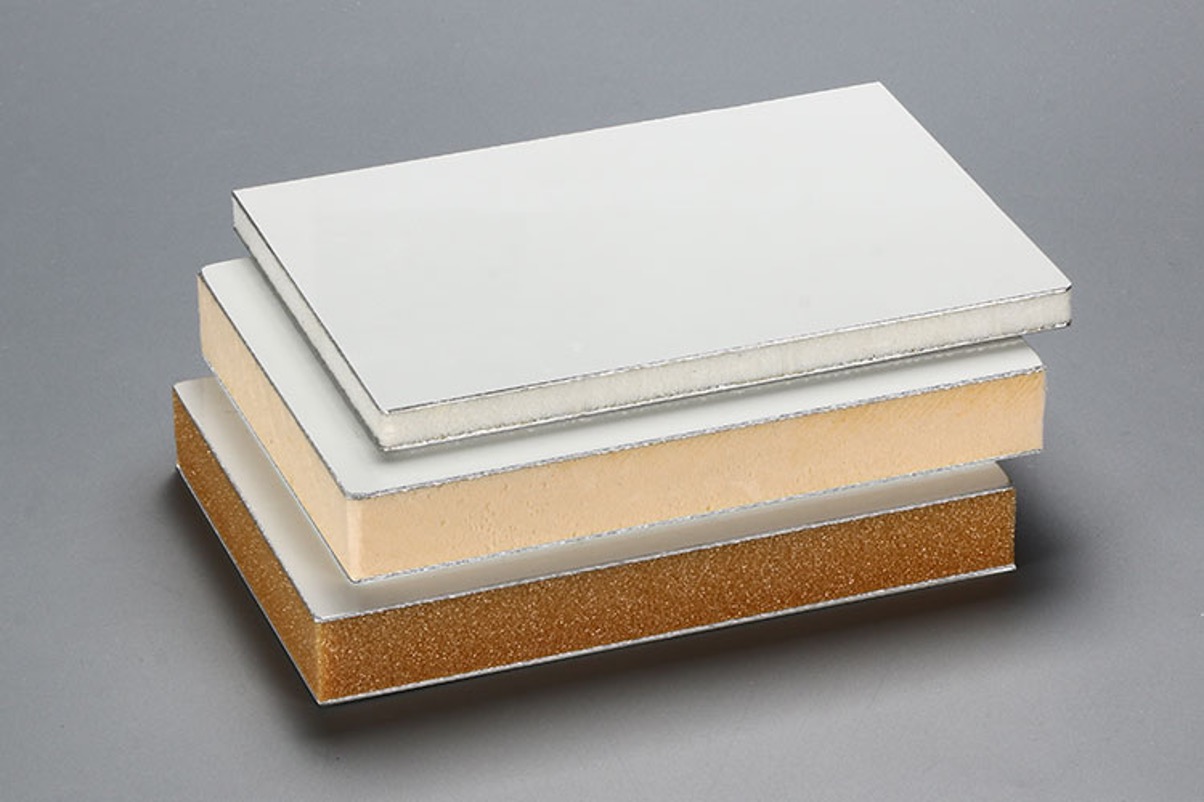

A sandwich panel is a composite building material made up of two outside layers (known as facings) and a core material between them. The facings are often constructed of metal, such as steel or aluminum, and the core material can be expanded polystyrene (EPS), polyurethane foam (PU), mineral wool, or aluminum honeycomb.

Sandwich panels are commonly utilized in construction due to their superior thermal insulation, lightweight design, and structural integrity. They provide energy efficiency, fire resistance, and sound insulation. The panels are simple to install, lowering construction time and costs. Sandwich panels are commonly used for roofing, wall cladding, partition walls, cold storage facilities, industrial buildings, and modular construction.

Sandwich panels can be classed according to a variety of factors, including the type of face material, the core material, and their intended application. Here are several typical types of sandwich panels:

It’s worth noting that the classification of sandwich panels can differ depending on regional or industry-specific rules and practices. As a result, it is always suggested to check individual manufacturers or local legislation to ensure appropriate classification and selection of sandwich panels for a certain application.

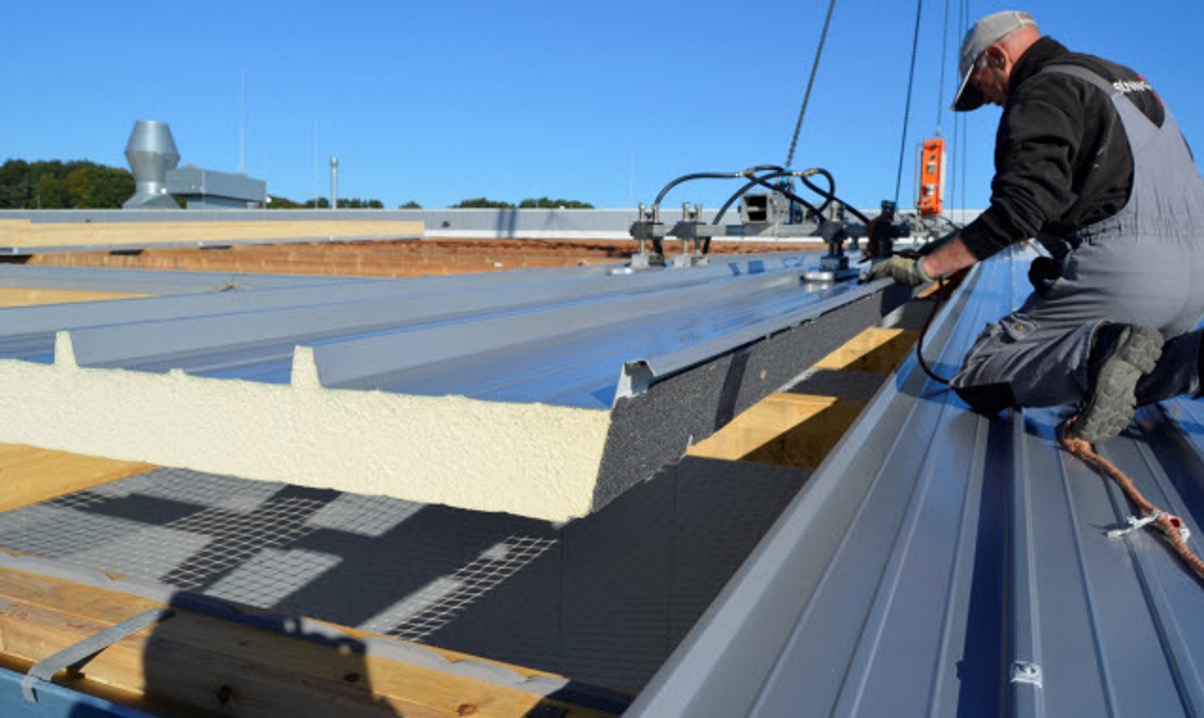

Sandwich panels are widely utilized in roof applications due to their superior thermal insulation, structural strength, and ease of installation. Here are some important points about sandwich panel roofing:

Sandwich panel roofs offer structural support to buildings. The panels are made up of hard facings, which are commonly composed of aluminum, and a core material that strengthens and stabilizes the roof structure. The core material can be foam, mineral wool, or any suitable substance.

Sandwich panel roofs provide great thermal insulation. The core material, such as EPS or PU foam, provides excellent insulation, minimizing heat transfer and helping to keep the building at a reasonable temperature. This insulating feature improves energy efficiency and can lower heating and cooling costs.

Sandwich panel roofs are built to endure a variety of weather situations. The sandwich panels’ aluminum facings provide durability and protection from rain, snow, wind, and UV radiation. Proper panel installation and sealing create a weather-tight roof system that prevents water leaks and moisture intrusion.

Sandwich panel roofs provide aesthetic variety. Aluminum facings can be tailored in terms of color, texture, and finish to meet the desired architectural style. This enables for visually pleasing roofs that suit the overall building design.

Sandwich panel roofs are manufactured off-site, making for a quick and efficient installation. The panels are lightweight, making them easy to move and carry. They are simple to assemble and install on the roof structure, cutting down on construction time and labor expenses.

Fire-resistant sandwich panel roofs are available, which provide additional fire protection. The use of fire-resistant facings and core materials ensures that the building meets fire safety criteria while also adding an extra layer of safety.

Sandwich panel for the roof is long-lasting and low-maintenance. The sandwich panel aluminum is corrosion-resistant, and the inner materials are intended to withstand the environment. Regular inspection and maintenance, such as cleaning and inspecting seals, ensures that the roof system lasts and performs well.

When choosing a sandwich panel for a roof, contact professionals like architects, engineers, or roofing specialists to ensure correct design, installation, and adherence to local building laws and regulations.

Installing a sandwich panel house requires various processes and concerns. This is a general guideline for the installation process.

Begin with preparing the foundation for the sandwich panel home. This usually entails leveling the ground, digging the space, and pouring a concrete foundation or building a suitable base to anchor the panels to.

Determine the house’s layout and dimensions using the design and floor plan. Mark the positions of the foundation’s walls, doors, windows, and any other openings to use as a guide during installation.

To install wall panels, start with the corners. Secure the first corner panel to the foundation with the appropriate bolts and ensure it is plumb and level.

Connect succeeding panels using interlocking systems, adhesive bonding, or mechanical fasteners according to the manufacturer’s recommendations. Make sure the panels are properly aligned and fit snugly together.

As you proceed, install windows, doors, and other openings in accordance with the plan. Seal and waterproof these openings to avoid water ingress.

To install roof panels, follow the same process as for wall panels, ensuring perfect alignment and tight connections.

Seal the joints between roof panels to prevent water leaks.

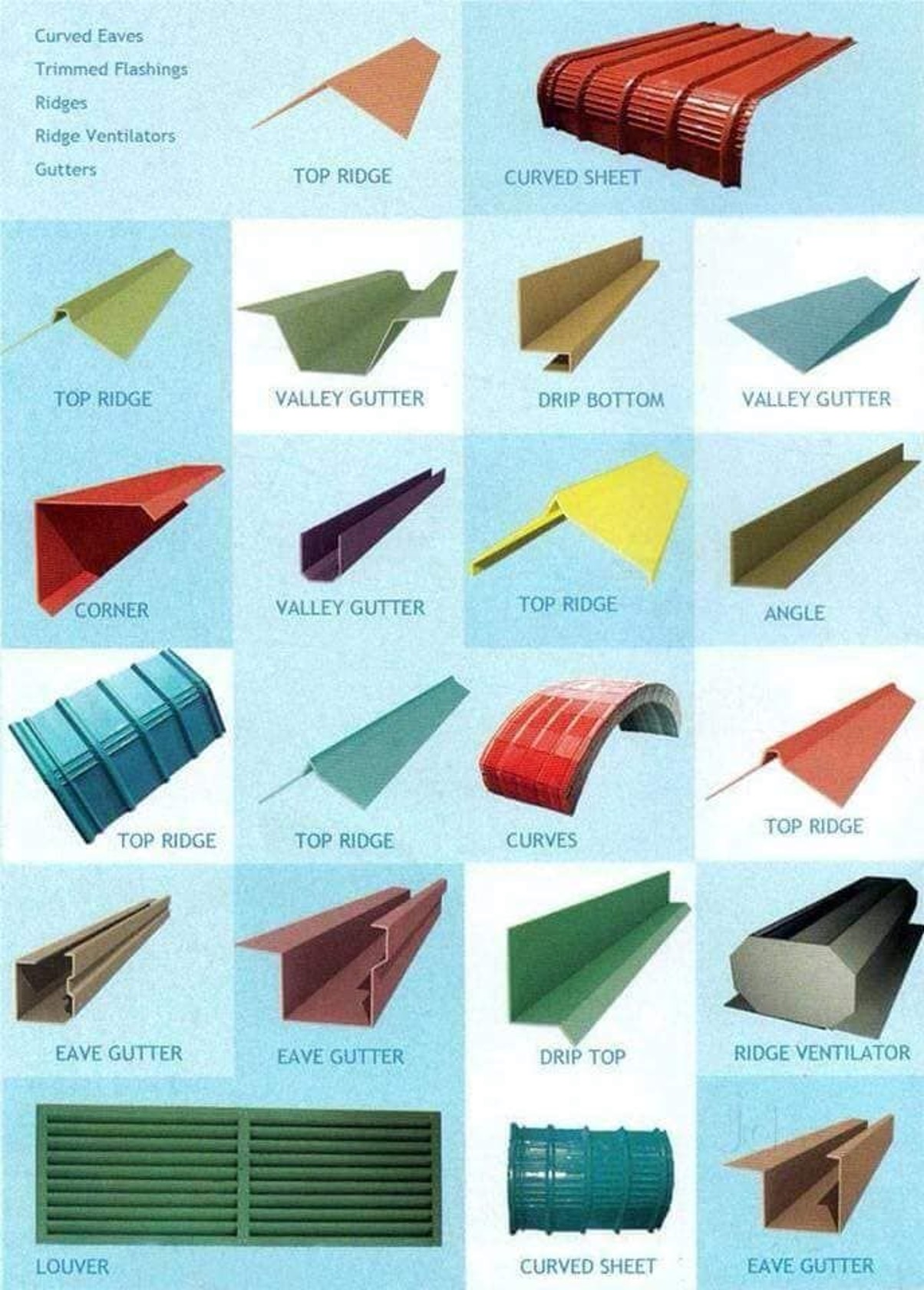

Install any roof accessories, such as vents, skylights, or chimneys, as needed.

Once the walls and roof panels are in place, install the electrical wiring, plumbing systems, and other utilities as specified in the building plans. Consult with professionals to ensure that you are following safety norms and regulations.

Finish the interior with insulation, drywall installation, flooring, painting, and any other requested finishes. Throughout this phase, adhere to normal construction standards and local building codes.

Use outside finishes such as siding, cladding, or paint to protect the sandwich panels from the elements while also improving the house’s looks.

Throughout the installation procedure, make sure to follow the manufacturer’s recommendations for the sandwich panels you’re using. These methods may differ depending on the type of sandwich panel and manufacturer guidelines.

It is also recommended to hire professionals, such as architects, engineers, and contractors that have expertise dealing with sandwich panel construction, to ensure appropriate installation and compliance with local rules and building requirements.

Sandwich panel prices vary depending on the thickness of the panel and the insulation core material used. The cheapest option is an EPS core sandwich panel. However, to assure project quality and long-term usefulness. Sandwich panels are the finest choice for thermal conductivity, sound insulation, waterproofing, and fire resistance. Examples include PU sandwich panels, Rockwool sandwich panels (mineral wool), and glass wool. Sandwich panel roof prices range from more than 200,000 to 800,000 VND/m².

The sandwich panel price listed above is for reference only. Prices fluctuate throughout the seasons.

Finally, sandwich panels have evolved as a highly adaptable and effective answer for modern building. These panels, with their unique composition of a core material sandwiched between outer layers, provide a variety of benefits. Sandwich panels help to create sustainable and comfortable living environments through their outstanding insulation capabilities and increased energy efficiency. Their lightweight yet durable design makes them simple to handle and install, resulting in shorter construction periods and cost savings. Sandwich panels continue to evolve as technology advances, providing creative design alternatives and satisfying a wide range of architectural objectives. Using sandwich panels is a wise decision for people looking for a long-lasting, versatile, and efficient building option.

EXPLORE MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com