Hot-rolled coil steel has become one of the most important and widely used materials in the construction and manufacturing industries. Through a special production process and unique properties, hot-rolled coil steel offers diverse and promising applications in various industrial sectors. In this article, we will delve deeper into the production process, characteristics, applications, and important considerations when using and preserving hot-rolled coil steel.

Hot-rolled coil steel is a type of steel produced through the hot rolling process at high temperatures, typically exceeding 1000 degrees Celsius. During this process, the steel billet can undergo changes in properties, size, and shape to create steel products as required.

Hot-rolled coil steel typically has a characteristic black-blue surface with an oily sheen. Its thickness usually ranges from 1mm and above. The edges of the coil steel are processed to remove sharpness, creating a neat appearance.

However, when hot-rolled coil steel is exposed to outdoor conditions for an extended period, it is susceptible to environmental influences. The surface of the coil steel may undergo oxidation and turn red due to the formation of rust.

To maintain the quality and proper preservation of hot-rolled coil steel, preventive measures and corrosion protection are essential, such as applying anti-corrosion coatings or storing it in low-humidity environments.

SEE MORE: STAVIAN HOT-ROLLED STEEL PRICES

Hot-rolled coil steel offers several production advantages, such as:

Cold-rolled steel is hot-rolled steel that has undergone additional processing to improve its mechanical properties and dimensions. During the cold rolling process, the hot-rolled steel is cooled through a series of different rollers at room temperature. As the material is no longer hot and is more ductile, it requires significantly higher pressure to compress it into the desired shape. While this process can be more laborious and costly compared to hot rolling, it can achieve tighter dimensional tolerances and better surface quality.

Compared to hot-rolled steel, cold-rolled steel offers several advantages:

The hot-rolled coil steel production process begins with collecting the main raw materials. Iron ore is extracted from iron ore mines and then transported to steel manufacturing plants along with other crucial materials. Steel producers collaborate with iron ore suppliers and thermal power plants.

Once sufficient raw materials are available, the hot-rolled coil steel production process involves various stages and processing procedures. Firstly, iron ore is crushed and refined to remove unwanted impurities.

Next, the iron ore is fed into a smelting furnace or blast furnace to separate iron and slag. After the separation, the iron and slag are used to produce hot-rolled coil steel.

The hot rolling process is a critical step in hot-rolled coil steel production. The iron and slag are fed into a hot rolling mill, where they are heated to high temperatures. The hot rolling process transforms the iron and slag into hot-rolled coils with the desired thickness and shape. Subsequently, the hot-rolled coil steel can undergo surface treatment to remove scale and enhance colorfastness and corrosion resistance.

To achieve good quality and properties for hot-rolled coil steel, some critical factors need to be considered.

Temperature and heating time impact the hardness and elasticity of the steel.

The alloy composition of hot-rolled coil steel can be adjusted to achieve the necessary mechanical properties and strength.

The rolling process, including pressure and rolling speed, influences the structure and characteristics of the steel.

Lastly, surface treatments like descaling and galvanization can improve the colorfastness and corrosion resistance of hot-rolled coil steel.

Hot-rolled coil steel plays a crucial role in infrastructure construction, industrial manufacturing, and consumer goods supply. Its versatility and superior properties cater to diverse needs in various industries, ensuring safety and performance in usage. Below are some specific applications of hot-rolled coil steel.

With excellent load-bearing properties, hot-rolled coil steel enhances the strength and rigidity of constructions, ensuring safety and stability. As such, it is widely used in constructing high-rise buildings, bridges, large-scale structures, etc.

In the automotive industry, hot-rolled coil steel is used to manufacture load-bearing parts such as chassis frames, trunk lids, and cabin walls.

In the railway sector, hot-rolled coil steel is utilized to create rail tracks and infrastructure structures such as bridges and pipelines.

With its ductility and corrosion resistance, hot-rolled coil steel increases the lifespan and efficiency of household appliances. It is used in manufacturing refrigerators, air conditioners, and washing machines.

Hot-rolled coil steel possesses excellent mechanical properties, improving the strength and load-bearing capacity of mechanical equipment. In the mechanical engineering industry, it is used to produce machine parts, machine frames, and mechanical tools.

When using and preserving hot-rolled coil steel, some important considerations ensure safety and maintain its quality:

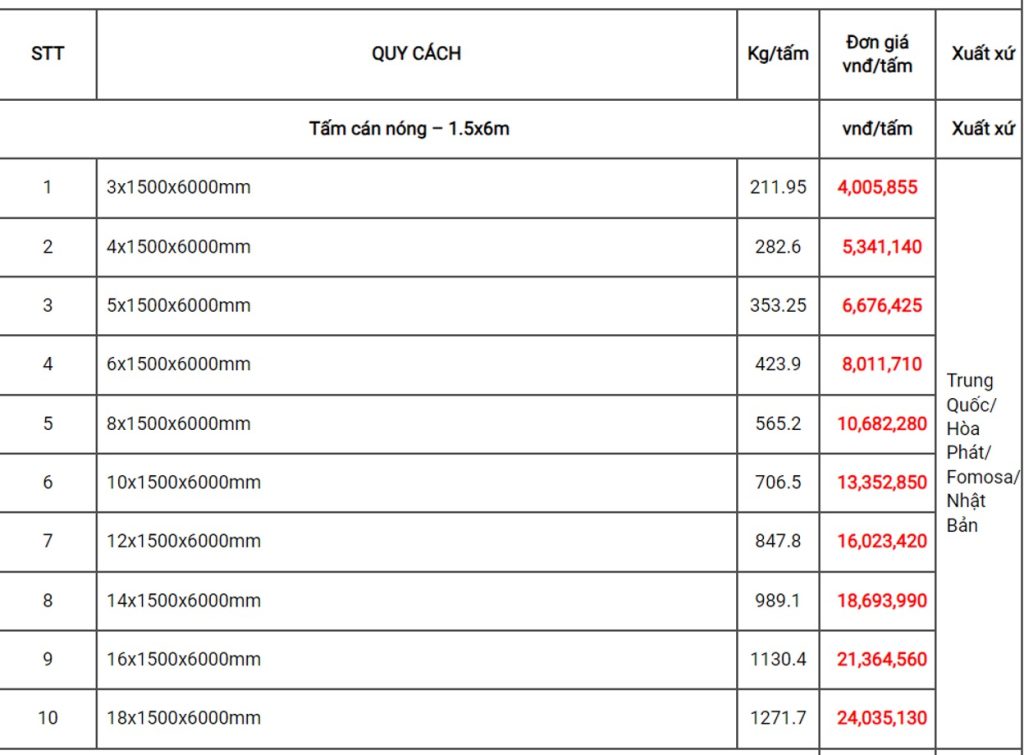

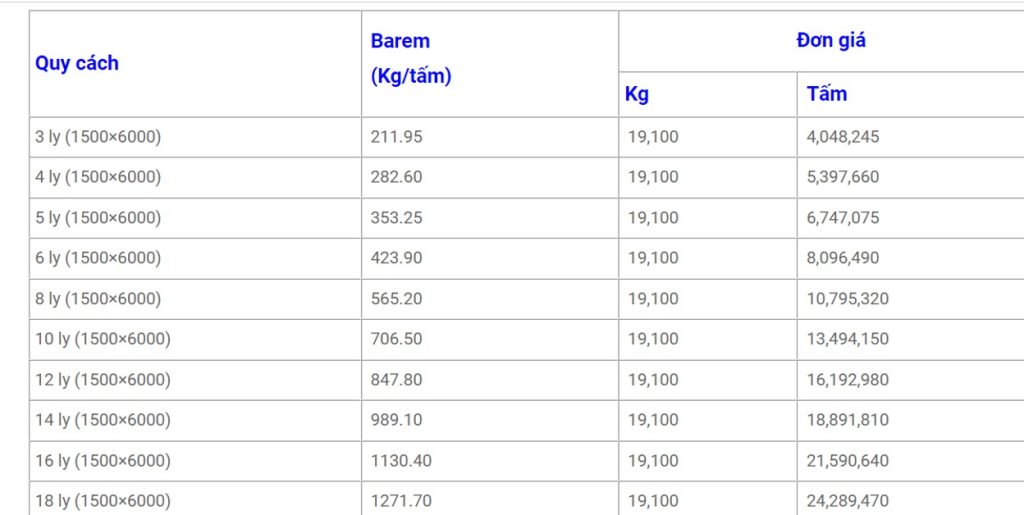

Steel prices can vary depending on market demand, supply situations, or overall economic conditions. Below are some hot-rolled coil steel price tables to give an idea of the relevant price ranges.

Please note that steel prices can fluctuate depending on the market. For the most accurate price information, we recommend contacting steel suppliers directly to receive the latest updates.

In conclusion, through this article, we have gained an overview of hot-rolled coil steel – an essential material in the industrial sector. Whether you have an interest in or a need for steel products, feel free to contact us for advice and support.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com