Looking for Galvalume Steel Sheets? Discover the benefits, applications, and pricing for this flexible coated steel. Galvalume steel sheets provide better corrosion resistance due to their 55% aluminum-zinc alloy covering. They are long-lasting, adaptable, and appropriate for a variety of applications, including construction, automotive, and appliances. Our detailed overview explains the benefits of Galvalume steel sheets, their varied applications, and reasonable pricing alternatives. Discover the ideal option for your project and the benefits of Galvalume steel sheets today.

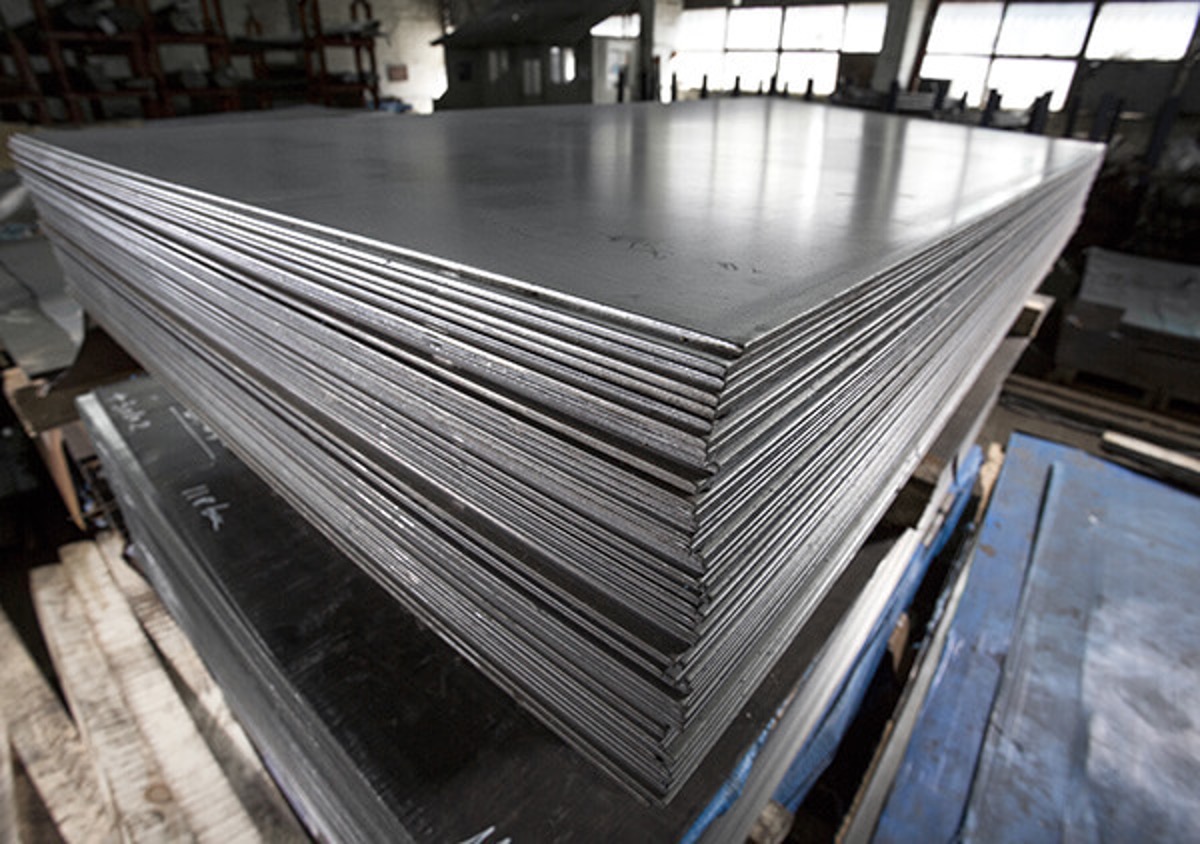

Galvalume steel sheets are coated steel products that combine aluminum’s corrosion resistance with zinc’s durability and galvanic protection. Galvalume, a registered brand of BIEC International Inc., refers to a coating made up of 55% aluminum, 43.5% zinc, and 1.5 percent silicon.

Galvalume steel sheets are made by pouring molten aluminum-zinc alloy on a steel substrate using a continuous hot-dip process. This results in a thin, homogenous, and tightly adherent covering that is highly corrosion resistant. The coating’s aluminum functions as a corrosion barrier, while the zinc galvanically protects any exposed or cut steel edges.

Galvalume steel sheets are subject to a variety of quality standards to guarantee that they meet specified performance and industry requirements. Some of the most often used quality criteria for Galvalume steel sheets include:

ASTM A792/A792M: The American Society for Testing and Materials (ASTM) produced this standard, which specifies the specifications for steel sheet coated with a 55% aluminum-zinc alloy using the hot-dip technique (Galvalume). It specifies parameters for coating weight, adhesion, mechanical qualities, and other important aspects.

EN 10346: This European standard defines the parameters for periodically hot-dip coated steel items (which are flat) used in cold forming. Part 3 of this standard describes the specific criteria for coating Galvalume steel sheets. It covers factors including coating mass, thickness, adherence, and surface quality.

JIS G3321: The JIS G3321 standard specifies hot-dip 55% aluminum-zinc alloy-coated steel sheets and coils, popularly known as galvalume. It establishes specifications for coating weight, adhesion, chemical composition, and mechanical qualities.

ISO 9364: This International Organization for Standardization (ISO) standard establishes rules for applying metallic and other inorganic coatings on steel. It covers numerous coating types, including Galvalume, and specifies coating thickness, adhesion, and surface conditions.

These are just a few instances of the quality requirements that Galvalume steel sheets may have to meet. To ensure compliance and quality assurance, refer to the relevant standards that apply to your region, industry, and project requirements. Furthermore, producers may use their own internal quality control systems and certifications to ensure the consistency and dependability of their Galvalume steel products.

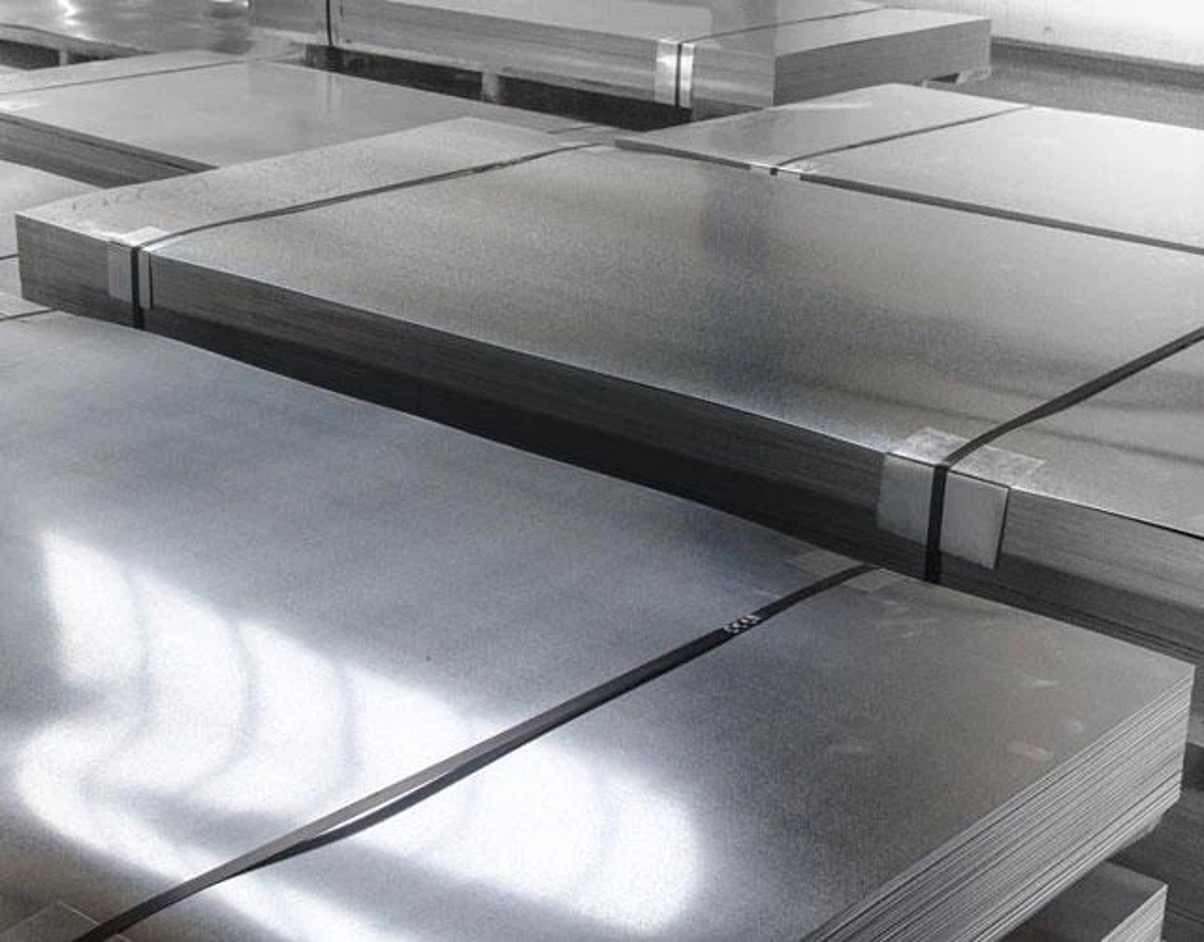

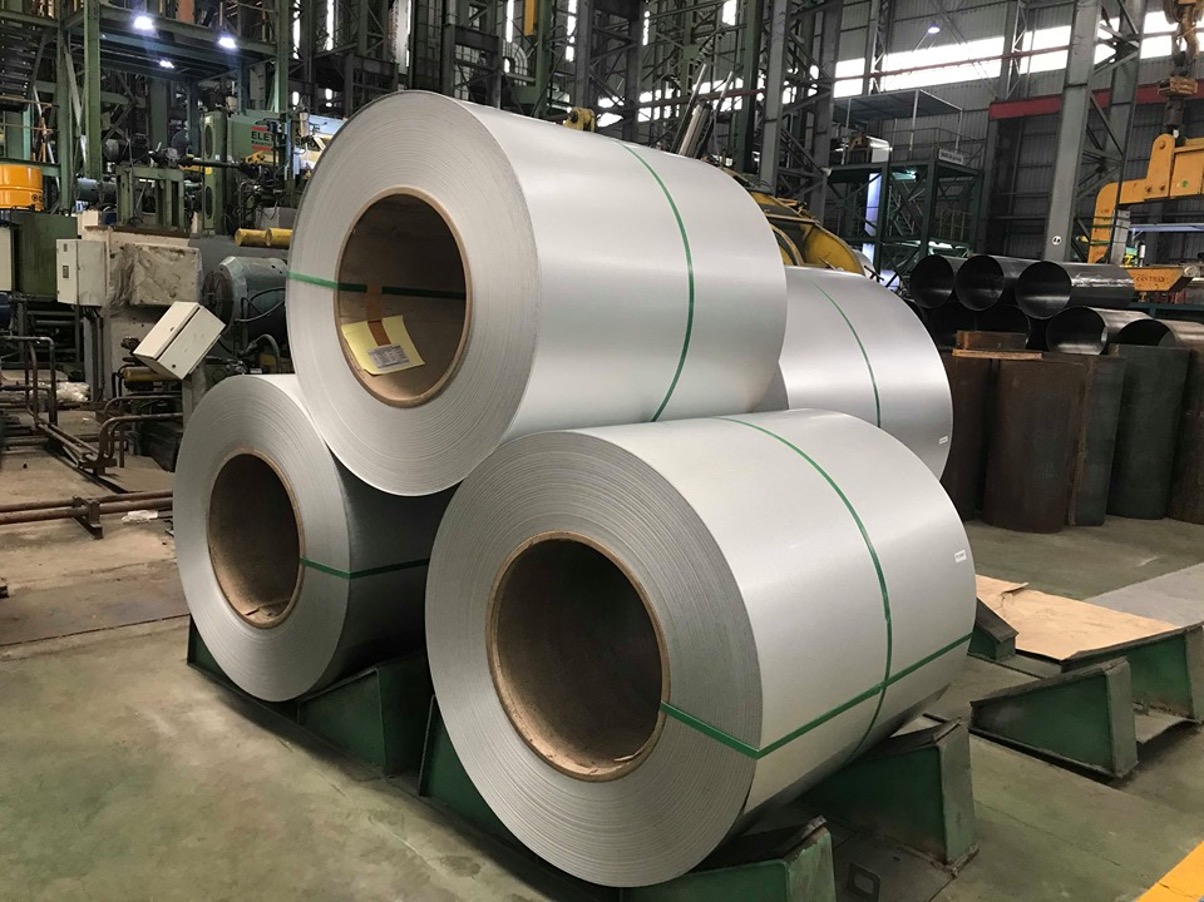

Galvalume steel sheets in coil have various advantages over other forms of coated steel products:

Galvalume steel sheets have higher corrosion resistance than ordinary galvanized steel. The combination of aluminum and zinc in the coating forms a corrosion barrier, providing long-lasting protection even in hostile situations.

Galvalume steel sheets are extremely durable and can endure the demands of a wide range of applications. The steel substrate provides strength and structural integrity, while the aluminum-zinc coating adds additional protection against scratches, abrasion, and other mechanical damage.

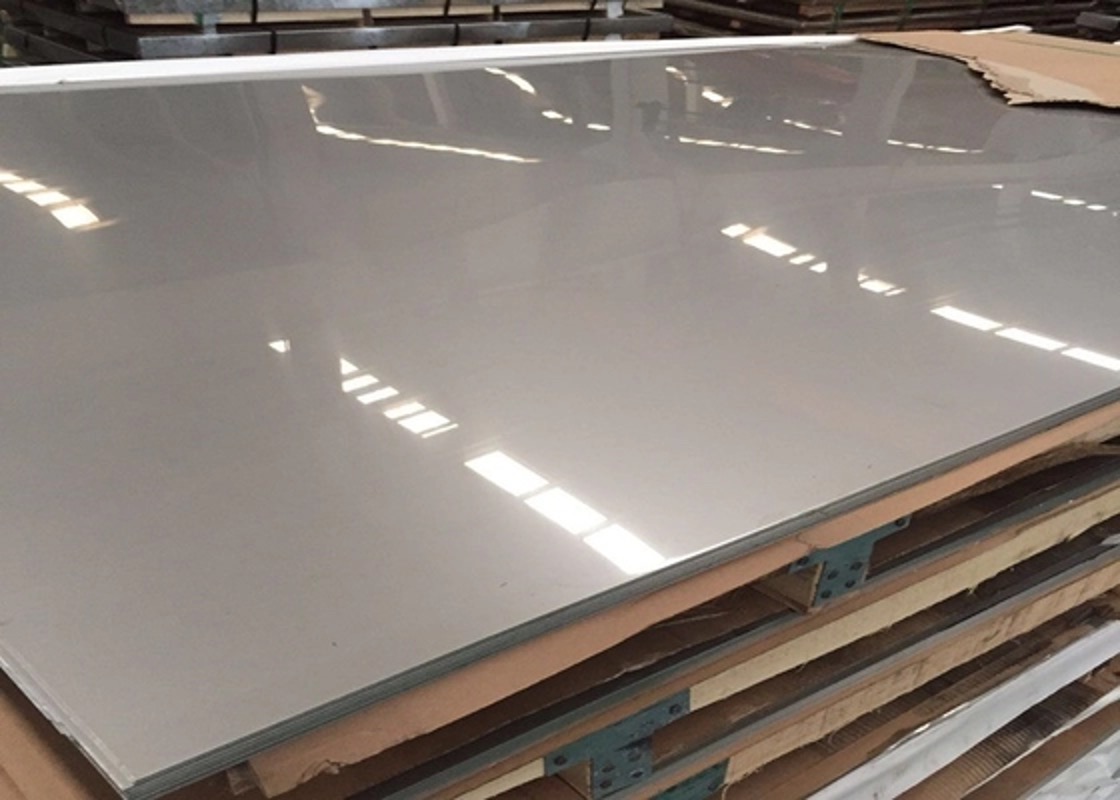

Galvalume steel sheets have outstanding heat reflective characteristics. The coating’s aluminum reflects a substantial amount of solar radiation, which helps to reduce heat absorption and keep temperatures lower in roofing and siding applications. This can help improve energy efficiency and reduce cooling expenses.

Galvalume steel sheets have an appealing appearance due to their smooth, uniform, and metallic surface. They come in a variety of colors and finishes, giving for flexible design options in architectural and construction applications.

Because Galvalume steel contains both aluminum and zinc, it resists rust, fading, and other forms of deterioration well. This leads to a longer lifespan than many other types of coated steel goods, lowering maintenance and replacement expenses over time.

Galvalume steel sheets in coils offer a cost-effective alternative for a variety of applications. While the initial cost may be slightly more than other options, Galvalume steel’s improved corrosion resistance and durability can result in long-term cost savings due to decreased maintenance, a longer lifespan, and a lower frequency of replacement.

Overall, the combination of improved corrosion resistance, durability, heat reflectivity, aesthetic appeal, lifespan, and cost-effectiveness makes Galvalume steel sheets in coil an excellent choice for a variety of applications in construction, roofing, siding, and other industries.

Several factors can influence the pricing of Galvalume steel sheets. This includes:

Transportation expenses, import/export tariffs, taxes, and local market conditions can all affect the price of Galvalume steel sheets in different regions. For example, delivering Galvalume steel sheets to a remote location may result in greater transportation costs, which can affect the ultimate pricing.

Galvalume steel sheets with specified quality standards or certifications, such as ISO certificates or industry-specific approvals, may attract a premium price. These certifications and standards assure that the product fulfills specific performance and quality requirements, which might lead to higher production costs.

Price volatility in the steel sector, especially Galvalume steel, can be caused by a variety of variables such as changes in global economic conditions, geopolitical events, and natural disasters. These market swings can affect the availability and pricing of raw materials, resulting in price discrepancies.

Individual suppliers’ pricing tactics, operational efficiency, and overhead costs might influence the price of Galvalume steel sheets. Different suppliers may have differing degrees of knowledge, production capacities, and distribution networks, which can all have an impact on pricing structures.

Long-term contracts or agreements between buyers and suppliers might affect the pricing of Galvalume steel sheets. Volume commitments, pricing formulas, and other factors agreed in these contracts can have an impact on overall pricing stability over a given time period.

Inflation, exchange rates, and interest rates can all have an indirect impact on Galvalume steel sheet prices. These factors can have an impact on raw material, production, and financing expenses, eventually impacting the product’s final price.

Strict environmental rules may compel steel firms to invest in pollution control technologies, waste management systems, or sustainable practices. Compliance with these rules might increase production costs and potentially affect the price of Galvalume steel sheets.

When determining the cost of Galvalume steel sheets, it is critical to examine all of these factors and their potential impact on pricing. Market conditions, individual project requirements, and the overall value proposition provided by various vendors should all be considered when making informed judgments.

In conclusion, Galvalume steel sheets have multiple advantages, making them a popular choice for a variety of applications. The 55% aluminum-zinc alloy coating offers excellent corrosion resistance, assuring long-term endurance. Because of their adaptability and strength, these sheets are used in a variety of industries, including construction, automotive, and appliances. Furthermore, Galvalume steel sheets have affordable pricing alternatives, allowing for cost-effective solutions without compromising quality. Whether you’re searching for dependable corrosion protection or a long-lasting material for a specific project, Galvalume steel sheets have numerous benefits, making them an ideal solution for your application requirements.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com