Discover everything there is to know about Vietnam ingots, including production, specifications, and market trends. Learn about the importance of aluminum ingots in numerous sectors and the rising need for premium ingots. This detailed reference will keep you up to date on Vietnam’s participation in the aluminum ingot industry.

The general position in Vietnam’s ingots industry is as follows:

Manufacturing Capacity: Ingot manufacturing capacity in Vietnam has increased significantly in recent years. To suit domestic and international demand, the country has constructed and expanded a number of ingot manufacturing plants.

Export Performance: Vietnam has emerged as one of Southeast Asia’s leading ingot exporters. Vietnamese ingots are exported to a variety of countries throughout the world, primarily to Asian, European, and North American markets.

Diverse Ingots: Vietnam manufactures a broad variety of ingots, including steel ingots, aluminum ingots, and other forms of ingots (particularly aluminum ingots, which we will discuss further below; please continue reading). The industry meets the diverse needs of several industries, including building, manufacturing, and engineering.

Quality Control: The production technology used in Vietnam’s ingots sector has advanced significantly, assuring that the ingots produced fulfill international quality standards. To improve the overall quality of ingots, industry companies have invested in innovative technology, quality management systems, and personnel training.

Government Support: The Vietnamese government has put in place a number of programs and efforts to help the ingots sector expand and thrive. This includes tax breaks, investment incentives, and steps to boost the industry’s competitiveness.

Domestic Consumption: In addition to exports, domestic consumption of ingots in Vietnam has expanded. The burgeoning construction and manufacturing industries, as well as infrastructure development initiatives, all contribute to the country’s increased need for ingots.

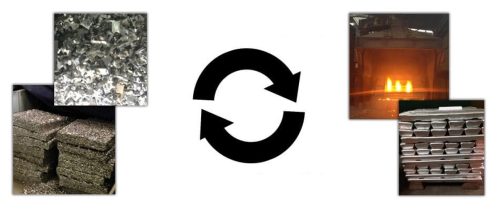

Environmental Concerns: The Vietnamese ingots industry is increasingly concerned with environmental sustainability. To reduce their environmental imprint, businesses are using eco-friendly practices such as energy-efficient technologies and waste management systems.

Continuous Growth Potential: With Vietnam’s continued economic development and modernization, the ingots industry is likely to flourish. The growing demand for ingots, both domestically and abroad, opens up potential for future expansion and investment in the sector.

It should be noted that the situation of Vietnam’s ingots sector may be influenced by economic conditions, market dynamics, and government policies. Understanding the current state and future possibilities of Vietnam’s ingots business requires keeping up with the latest market trends, policies, and investments.

Vietnamese aluminum ingots have a variety of qualities and attributes that make them ideal for a variety of applications. These ingots provide exceptional performance and reliability because of their high purity, which frequently exceeds 99.7%. Vietnamese aluminum ingot alloy composition can be adjusted to individual specifications, incorporating metals such as copper, silicon, magnesium, and manganese. These alloying elements improve the strength, corrosion resistance, and other desirable attributes of the ingots.

In terms of mechanical properties, Vietnamese aluminum ingots exhibit impressive tensile strength, allowing them to withstand substantial loads without deformation or structural failure. They also possess a high yield strength, enabling them to endure stress and strain while maintaining their structural integrity. Additionally, these ingots demonstrate excellent corrosion resistance, making them suitable for applications in environments prone to moisture, humidity, or exposure to various chemicals.

Vietnamese aluminum ingots are well-known for their high machinability. They are easily formed, cut, drilled, and molded into required shapes, making them perfect for manufacturing operations requiring elaborate designs or accurate measurements. Furthermore, these ingots have outstanding thermal conductivity, allowing heat to be dissipated efficiently. Because of this, they are ideal for applications such as heat sinks, radiators, and other thermal management systems. Vietnamese aluminum ingots are normally manufactured in accordance with international standards such as ASTM or JIS, which ensure consistency in dimensions, tolerances, chemical composition, and mechanical qualities.

Vietnamese aluminum ingots provide a good balance of purity, alloy adaptability, mechanical strength, corrosion resistance, machinability, and thermal conductivity. These qualities and properties make them extremely valuable in a variety of industries, including construction, automotive, aerospace, and electronics.

The demand for aluminum ingot premium has been steadily rising as industries recognize the value and benefits it offers. Premium quality aluminum ingots are sought after due to their superior properties and performance compared to standard ingots. Industries such as automotive, aerospace, electronics, and construction are increasingly opting for aluminum ingot premium to meet their stringent requirements and ensure optimal performance in their applications.

One of the key factors driving the growing demand for aluminum ingot premium is the need for high-quality materials that can withstand challenging operating conditions. Premium ingots often exhibit enhanced mechanical strength, improved corrosion resistance, superior thermal conductivity, and better dimensional stability. These properties make them ideal for critical applications where reliability, durability, and precision are crucial. As industries continually strive for innovation and improved product performance, the demand for aluminum ingot premium is expected to continue its upward trajectory.

Furthermore, the market demand for aluminum ingot premium is also driven by the increasing focus on sustainability and environmental responsibility. Premium ingots are often manufactured using advanced processes that minimize energy consumption and reduce waste. This aligns with the growing emphasis on eco-friendly practices and the adoption of sustainable materials across various industries. As companies prioritize sustainability goals and seek greener solutions, the demand for aluminum ingot premium, with its superior properties and eco-friendly production methods, is anticipated to experience sustained growth in the coming years.

Vietnam is a major player in the worldwide aluminum ingots market, providing high-quality products that match international requirements. The country’s aluminum ingots business has grown significantly and has established itself as a reputable supply for consumers globally.

Here are criteria demonstrating Vietnam’s position in the global aluminum ingot market:

Vietnam aluminum ingots are known for their superior quality. Manufacturers in Vietnam use innovative technologies and strict quality control techniques to ensure that the ingots match the highest industry requirements. The manufacturing procedures conform to precise criteria, resulting in aluminum ingots that are long-lasting, corrosion-resistant, and ideal for a wide range of applications.

Vietnam manufactures a wide range of aluminum ingots to meet the needs of various industries. Primary ingots, secondary ingots, alloyed ingots, and specialty ingots for specific applications are examples of these. Customers can discover aluminum ingots with a variety of chemical compositions, sizes, and shapes to meet their needs.

The aluminum ingots business in Vietnam has a lot of expertise and experience. Manufacturers have gained vast understanding in aluminum smelting and casting, ensuring the creation of high-quality ingots. The professional staff and technical know-how of the industry contribute to the regular delivery of dependable aluminum ingots.

With a growing emphasis on environmental sustainability, Vietnam’s aluminum ingots industry is adopting eco-friendly practices. Manufacturers are increasingly implementing energy-efficient technologies and recycling processes to reduce energy consumption and minimize waste. This commitment to sustainability ensures that customers can source aluminum ingots produced with a focus on environmental responsibility.

Vietnam’s aluminum ingots offer a competitive advantage in terms of pricing. The country benefits from favorable production costs, including factors such as labor, raw materials, and energy. This allows manufacturers to offer cost-effective aluminum ingots without compromising on quality, making them an attractive choice for customers seeking both value and performance.

Vietnam’s aluminum ingots have gained recognition in the international market. The country exports aluminum ingots to various regions, including Asia, Europe, and North America. Its reputation for quality, low price, and reliable delivery has positioned Vietnam as a preferred supplier for global consumers in need of aluminum ingots.

As Vietnam continues to grow its aluminum ingots industry, the country is positioned to contribute considerably to the global supply chain. Vietnam, with its focus on quality, sustainability, and affordable price, provides customers with a dependable source of high-quality aluminum ingots for a wide range of industrial applications.

Read more

What exactly is billet 6061 aluminum? Price list today

Exploring the Properties and Applications of Billet Alloy and Non-Alloy

Understanding Vietnam ingots is essential for industries that rely on aluminum for their manufacturing processes. With their excellent quality and diverse applications, Vietnamese aluminum ingots play a significant role in sectors such as construction, automotive, aerospace, electronics, and more. As industries continue to evolve and seek advanced materials that offer exceptional performance and sustainability, the demand for Vietnam ingots, including premium quality options, is expected to rise.

By staying informed about Vietnam ingots and the evolving market dynamics, businesses can make informed decisions, optimize their operations, and leverage the benefits that these high-quality aluminum ingots bring. Whether it’s exploring new applications or ensuring the highest standards of quality and performance, this article has provided the necessary knowledge to navigate the world of Vietnam ingots effectively.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com