Discover the benefits, applications, and pricing of PPGL Steel in this thorough overview. PPGL Steel provides numerous advantages, including superior corrosion resistance, durability, and aesthetic appeal. Discover how this flexible material is utilized in a variety of applications, including roofing, cladding, automobile components and appliances. Understand the elements that determine PPGL Steel pricing, including raw material costs, coating parameters, and market dynamics. Whether you are a builder, architect, or homeowner, this article will help you understand the qualities and pricing of PPGL Steel. Make informed selections and choose PPGL Steel‘s cost-effective solutions for your building or manufacturing projects.

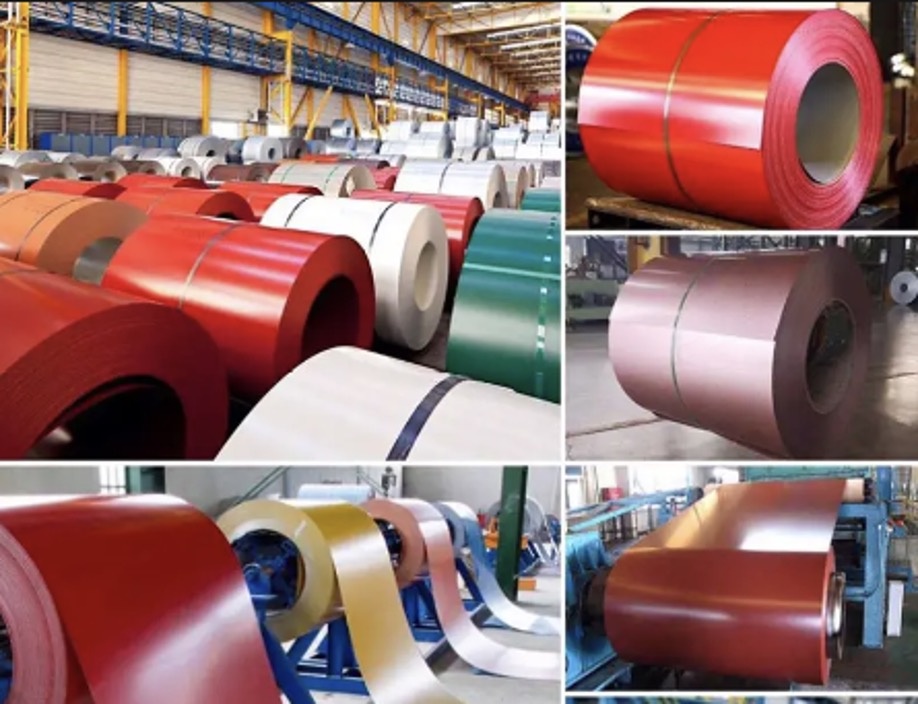

The acronym PPGL stands for “Prepainted Galvalume Steel” or “Prepainted Galvanized Steel.” It is a coated steel that combines galvanized steel’s corrosion resistance with the better durability and heat reflectivity of aluminum-zinc alloy-coated steel (Galvalume).

To make PPGL steel, a protective layer of paint or coating is applied to the Galvalume or galvanized steel base. This coating gives additional protection against corrosion, improves the appearance of the steel, and increases its longevity.

PPGL (Prepainted Galvalume Steel) coil has numerous benefits, including:

The combination of Galvalume steel’s natural corrosion resistance and the protective pre-painted coating makes PPGL steel coil extremely corrosion resistant. It offers long-term rust protection, even in tough situations or high moisture levels.

The Galvalume steel substrate of PPGL coil is extremely durable and strong. It has a high tensile strength, making it difficult to distort and damage. The pre-painted covering increases the coil’s durability by protecting it from scratches, abrasion, and weathering.

PPGL coil is available in a variety of colors, coatings, and patterns, providing excellent design versatility. It enables architects, designers, and manufacturers to fulfill their aesthetic goals, whether for roofing, cladding, or other uses. The color and finish selections retain their vibrancy and attractiveness throughout time.

PPGL coils with reflecting coatings can assist reduce heat absorption in buildings, making them more energy efficient. The coil’s capacity to reflect sunlight can help to cut cooling expenses while also creating a more comfortable indoor environment.

Installation and maintenance are simplified by the lightweight and easy-to-handle nature of PPGL coil. It requires less care because the pre-painted coating serves as a protective barrier, eliminating the need for periodic cleaning or repainting.

PPGL coil has good impact resistance, making it ideal for applications that require durability against physical impacts. It can survive hailstorms, flying debris, and other types of impact damage.

PPGL coil is an environmentally sustainable option. The Galvalume steel substrate comprises a considerable amount of recycled steel, which contributes to resource conservation. Furthermore, the pre-painted coating can be created using ecologically friendly paints with low VOC emissions, reducing the environmental impact.

Despite its multiple benefits, PPGL coil is cost-effective in the long run. Its enhanced corrosion resistance and longevity lead to lower maintenance and replacement expenses over time.

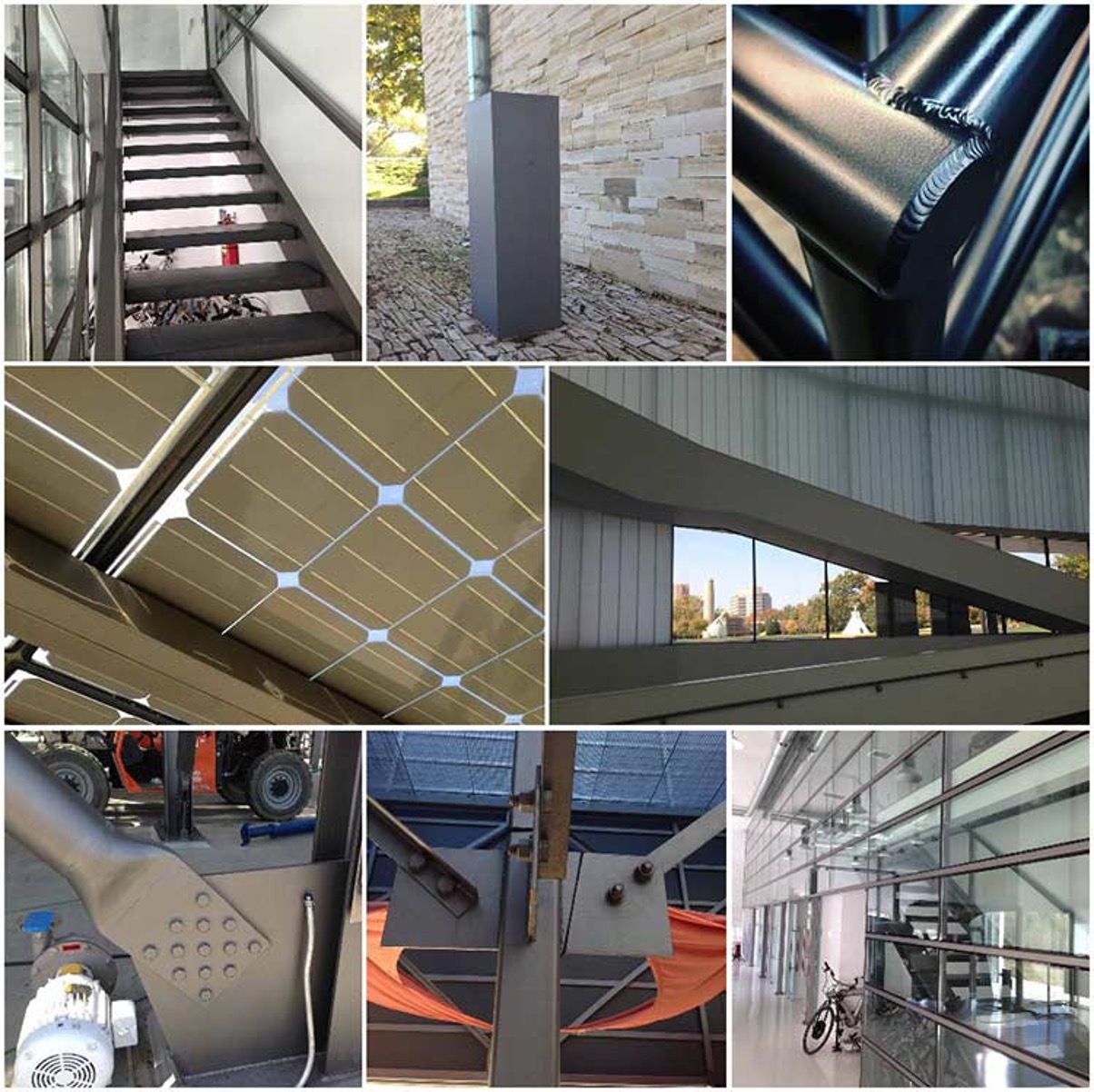

PPGL coil is used in a variety of industries, including construction, automotive, and appliances. It is widely utilized in roofing, wall panels, garage doors, agricultural structures, and other architectural and industrial applications.

Overall, the specific benefits of PPGL steel coil include corrosion resistance, durability, visual variety, energy economy, ease of installation, and environmental sustainability. These characteristics make it an excellent solution for a wide range of applications, ensuring long-term performance and increasing project value.

The PPGL (Prepainted Galvalume Steel) coil has a wide range of uses in numerous sectors. Here are some popular applications for PPGL steel coil:

PPGL steel coil is widely utilized for roofing applications in residential, commercial, and industrial structures. The pre-painted coating not only looks good, but it is also corrosion resistant and long-lasting, protecting the roof from the elements.

PPGL coil is used in cladding applications to cover the outer walls of buildings. It has a visually beautiful surface and protects against environmental variables such as moisture, UV radiation, and temperature fluctuations.

PPGL steel coil is used to manufacture wall panels for both internal and external purposes. The pre-painted coating offers a diverse variety of color options, allowing designers to create visually appealing and durable wall surfaces.

PPGL coil is widely utilized in the manufacture of garage doors. Its corrosion resistance, durability, and visual adaptability make it a great material for garage door panels, ensuring long-term function while also improving the curb appeal of residential and commercial premises.

PPGL steel coil is used in the production of refrigerators, stoves, washing machines, and air conditioners. The pre-painted coating improves the appearance of these appliances while also protecting against scratches, stains, and corrosion.

PPGL coil is used in the automotive sector, mostly for body panels, trims, and decorative pieces. The pre-painted coating allows for personalization and offers an appealing finish, making it ideal for improving the looks of cars.

PPGL steel coil is utilized in barns, sheds, and storage facilities. It provides corrosion resistance, durability, and protection from extreme weather conditions, ensuring the longevity of these buildings.

PPGL coil is used to create outdoor signage, billboards, and display systems. The pre-painted coating has brilliant colors, weather resistance, and durability, making it ideal for outdoor advertising and promotional displays.

PPGL steel coil is used to manufacture cabinets, shelves, and decorative pieces. The pre-painted finish offers a beautiful touch while protecting the furniture from wear, scratches, and moisture.

These are only a few examples of the numerous applications for PPGL steel coils. Its corrosion resistance, durability, aesthetic adaptability, and ease of installation make it an ideal choice for a variety of industries and applications.

The pricing of PPGL (Prepainted Galvalume Steel) coil is impacted by a variety of elements, each with varying degrees of impact.

Raw material costs have an important impact. The price of Galvalume steel, the base substrate, can change depending on raw material availability, global steel market circumstances, and trade barriers. Similarly, the cost of pre-painted coatings, which includes paint, primer, and other additives, can vary depending on raw material pricing, quality criteria, and the complexity of the coating composition.

Coating parameters can also influence the pricing. Higher-quality coatings with greater performance features, such as increased corrosion resistance or color retention, are typically more expensive. Coatings with particular features, such as heat-reflective or textured surfaces, may also cost more due to the additional production processes required.

The PPGL coil’s specifications, such as width, thickness, and length, can affect the pricing. Custom sizes or non-standard specifications may necessitate additional production steps or result in higher material waste, which can raise prices. Furthermore, the quantity and order size can affect the price. Larger orders frequently benefit from economies of scale, which allow for volume discounts or better pricing arrangements.

Market demand and supply dynamics are important considerations. If demand for PPGL steel coils is high but supply is restricted, prices are likely to rise. In contrast, if demand is low or there is excess supply in the market, pricing may become more competitive.

Currency exchange rates can affect prices, particularly in international commerce circumstances. Exchange rate fluctuations can affect the cost of imported raw materials as well as the competitiveness of pricing in various markets.

The geographical location of the manufacturer or supplier might also have an impact on the price. Production costs, labor costs, transportation charges, and local market conditions can all vary by region, resulting in price disparities.

Finally, market competition may influence the pricing of PPGL coil. When there are several suppliers competing for clients, prices might become more competitive as businesses try to attract buyers and increase market share.

These variables are interconnected and can change over time. Therefore, the price of PPGL coil should be evaluated by considering multiple factors and conducting a thorough assessment of the specific requirements, quality, and overall value proposition offered by different suppliers.

To summarize, PPGL Steel has several benefits, a diverse variety of applications, and cheap cost. Its superior corrosion resistance, durability, and visual appeal make it a popular choice for a variety of sectors. From roofing and cladding to automotive components and appliances, PPGL Steel demonstrates its versatility and dependability. Understanding the elements influencing pricing, such as raw material costs and market dynamics, is critical for making sound judgments. Whether you’re a builder, architect, or homeowner, researching the benefits and pricing of PPGL Steel will help you find cost-effective solutions for your building or manufacturing needs. Accept the benefits of PPGL Steel and realize its full potential for improving durability and beauty in your applications.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com