Finished aluminum wheels are a popular choice for many car enthusiasts due to their sleek appearance, lightweight properties, and excellent performance characteristics. However, maintaining their pristine look requires a keen understanding of the specific care they demand. With various types of finishes, from polished to painted or anodized, each requires a tailored approach to cleaning and protection.

In this article, Stavian Industrial Metal will help you delve into the intricacies of caring for finished aluminum wheels, offering expert advice on the best products and practices to ensure they remain in showroom condition, enhancing both the aesthetic appeal and resale value of your vehicle.

Finished aluminum wheels are a popular choice for many car enthusiasts

Aluminum alloy wheels have become a staple in the automotive industry, gracing the majority of modern vehicles. These wheels are renowned for their blend of strength, lightweight characteristics, and aesthetic charm, achieved through the incorporation of aluminum alloyed with trace amounts of other metals to bolster durability.

Unlike magnesium alloy wheels, which are lighter but more brittle and predominantly used in high-end sports or race cars, aluminum alloy wheels strike an ideal balance between performance and resilience. Typically weighing between 5-9 kg, they contribute to better fuel efficiency and improved handling.

Their versatility in design and finish also allows for a wide range of styles, making them a popular choice for both manufacturers and car enthusiasts aiming to elevate the look and performance of their vehicles.

Aluminum alloy wheels have become a staple in the automotive industry

Aluminum alloy wheels come in a variety of finishes, each offering distinct advantages and aesthetic appeal. Here are some of the most popular finished aluminum wheel’s types:

Many wheels feature combinations of these finishes, such as a diamond-cut face with painted inserts or powder-coated rims with a lacquer top coat. The additional lacquer layer helps guard against corrosion and enhances durability.

Given that wheels are often the dirtiest part of a car, regardless of finish, it’s crucial to use dedicated cleaning tools to avoid cross-contamination and protect the car’s bodywork. Essential tools include:

By following these maintenance practices and using the appropriate products for your wheel finish, you can keep your aluminum wheels looking pristine and ensure they enhance the overall appearance and value of your vehicle.

Painted & Lacquered Finished

Painted and lacquered wheels require similar care to the bodywork of a car. It’s important to avoid washing chemicals with extreme pH levels, as frequent exposure to highly acidic or alkaline products, commonly found at supermarket hand car washes, can etch the lacquer and potentially cause blistering and peeling. To ensure metal particles are neutralized and safely rinsed off, use a ferrous contamination remover. Ferrous contamination results from tiny particles of steel brake discs shredding and bonding to the wheel surface, which, if not removed, can cause pitting.

Regular cleaning is essential, and provided the wheels are protected, a dedicated wheel cleaning product is usually sufficient to remove any build-up of dirt, brake dust, and grime. Many modern wheel cleaners now include a ferrous removing agent, allowing one product to handle both tasks.

Washing and Protecting lacquered finished

Protecting lacquered wheels is similar to sealing paintwork, which is also lacquered to add shine and protect against UV fade, industrial and environmental fallout, and wash swirls. You can protect this type of wheel finish with either a wheel wax or ceramic sealant. However, ceramic sealants offer greater durability and can help protect against hot brake dust compromising the lacquer. Before applying a wax or sealant, the surface should first be refined by hand with a cleanser polish. In the case of ceramic sealants, a residue remover should be used to ensure a satisfactory bond with the wheel.

Powder Coated Finished

Powder coating is applied as a dry powder without the need for a solvent, differentiating it from conventional liquid paint. Typically applied electrostatically, the powder is then cured under heat, allowing it to flow and form a durable “skin.” This process results in a hard finish that is tougher than traditional paint. Powder-coated wheels are also lacquered similarly to painted wheels, meaning they can be cleaned and sealed using the same methods.

Anodised Finished

Anodizing involves using an electrochemical reaction to increase the thickness of the oxide layer on the wheel’s surface, making the finish an integral part of the wheel rather than a separate layer. Anodized wheels are sealed through a chemical process, typically resulting in a textured feel and availability in various colors.

Although naturally hard-wearing and resistant to weather and corrosion, anodized wheels should still be regularly treated for iron contamination and cleaned to preserve their finish. Once stained, they require chemical stripping to be refurbished. The best way to clean anodized wheels is with a mild car shampoo. Since anodized wheels are chemically sealed during the anodization process, they typically do not require additional wax or sealant.

Diamond Cut wheels are first painted in the selected color and then baked in an oven. Once dry, the wheel is mounted on a CNC (computer numerical controlled) lathe, where the face of the wheel is machined to achieve the metallic diamond cut pattern. The wheels are then finished with a spray of acrylic lacquer.

Even with protective lacquer, the diamond cut finish remains vulnerable to damage. If water seeps under the lacquer, it can stain the bare metal a milky color, which is hard to fix without completely stripping the lacquer. Diamond cut wheels cannot undergo repeated machining, as each process removes metal and eventually undermines the wheel’s structural integrity.

Diamond Cute Finished

To prolong their life, clean diamond cut wheels with a mild car shampoo or pH-neutral wheel cleaner, avoiding acid or alkaline-based cleaners, which can cause discoloration and corrosion. Due to the sharp edges, towel drying may result in threads or lint getting caught; using an air blower is a great way to ensure complete dryness.

It is essential to have access to areas where corrosion or staining may initiate. While ceramic sealants are durable and can last upwards of two years, even minor damage like a stone chip can allow salt ions to penetrate, leading to corrosion. Removing ceramic sealants requires machine polishing, making surface issues difficult to treat. Therefore, wheel waxes and polymer sealants are better choices for diamond cut finishes, as they can be removed to address any areas needing attention.

Split Rims Finished

Split rims are constructed from two or even three pieces of aluminum alloy bolted together, rather than being a single piece. They are frequently coated with lacquer to safeguard against corrosion and rust, although different sections may feature varied finishes. For instance, a split rim might have an anodized center piece, a lacquered middle, and a bare metal rim. Split rims are characterized by visible bolts holding the sections together, which can be located at either the front or rear of the wheel.

Due to their complex construction and susceptibility to corrosion, split rims are not typically used on everyday vehicles, as they require high maintenance. Cleaning split rims involves using a mild car shampoo or pH-neutral wheel cleaner, followed by careful rinsing and thorough drying. An air blower is the most effective method to ensure the wheel is completely dry, both front and back.

Ceramic sealants are not suitable for bare, unlacquered metal, so it’s advisable to protect split rims with a high-quality wheel wax. This will help maintain the wheel’s appearance and guard against contamination and corrosion.

Typically found on British classic cars as intricate wire wheels and popular in the American classic car scene, chrome wheels offer a high shine but can be challenging to maintain. Alkaline-based cleaning solutions will stain the metal, which can be removed by polishing, but it’s best to avoid this problem by using a mild car shampoo for cleaning. Because they are prone to corrosion, regular cleaning is imperative

Many chrome wheels on classic cars are lacquered by their owners to protect their appearance for longer. Determining whether a wheel is lacquered can be challenging without comparing it directly to a non-lacquered wheel. Hence, the safest approach is to wash using a gentle shampoo, employing a small, soft brush to remove any contaminants, and then using an air dryer to prevent water spots from forming. Alternatively, using an Aqua Gleam, a de-ionizing filter, can remove impurities from the water, eliminating the need for drying.

Chrome & Wire Wheels Finished

Although the chrome finish is delicate, it’s best protected with a wax or polymer-based sealant, which allows easy access to the surface if rust spots appear, as rust can quickly eat through the chrome. Using a mild shampoo to wash the wheels should prevent the removal of wax or sealant, so reapplication may not be necessary with each cleaning.

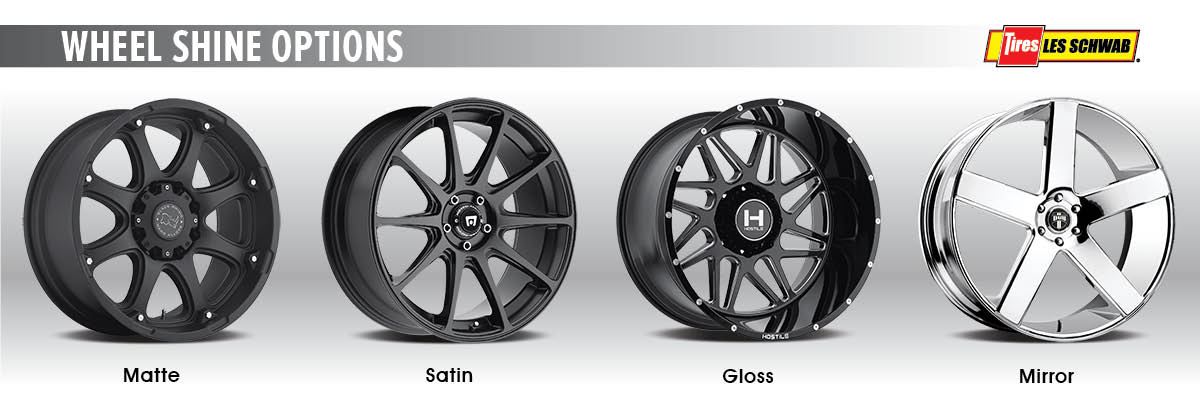

If you’re looking to customize the shine of your aluminum wheels, there are several options available. You can choose from matte (a flatter shine), gloss (high shine), satin (a balance between matte and gloss), and mirror (reflective) finishes. These finishes can be mixed and matched on different parts of the wheel face to create a unique look that suits your style.

4 Aluminum Wheel Shine Options

In conclusion, the world of finished aluminum wheels offers a diverse range of options tailored to both aesthetic preferences and practical considerations. Whether opting for painted and lacquered finishes for everyday durability, powder coatings for enhanced resilience, anodized options for specialized applications, or intricate diamond cut designs for a premium look, each variety necessitates tailored care to preserve its appearance and integrity.

Comprehending these differences ensures not just the durability and performance of your wheels but also elevates the overall attractiveness and resale value of your vehicle. By choosing and caring for the right finish, you can ensure your aluminum wheels continue to shine and stand out on the road for years to come.

EXPLORE MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com