This detailed guide will help you unlock the full potential of composite aluminum panels. Discover a wide range of possibilities for these panels, including building facades and interior design. Learn essential installation recommendations to ensure a smooth and successful installation experience. Explore the factors that influence composite aluminum panel pricing to make informed project decisions. Whether you’re an architect, designer, or contractor, this guide will teach you how to use composite aluminum panels‘ adaptability and aesthetic appeal to transform and elevate your building projects.

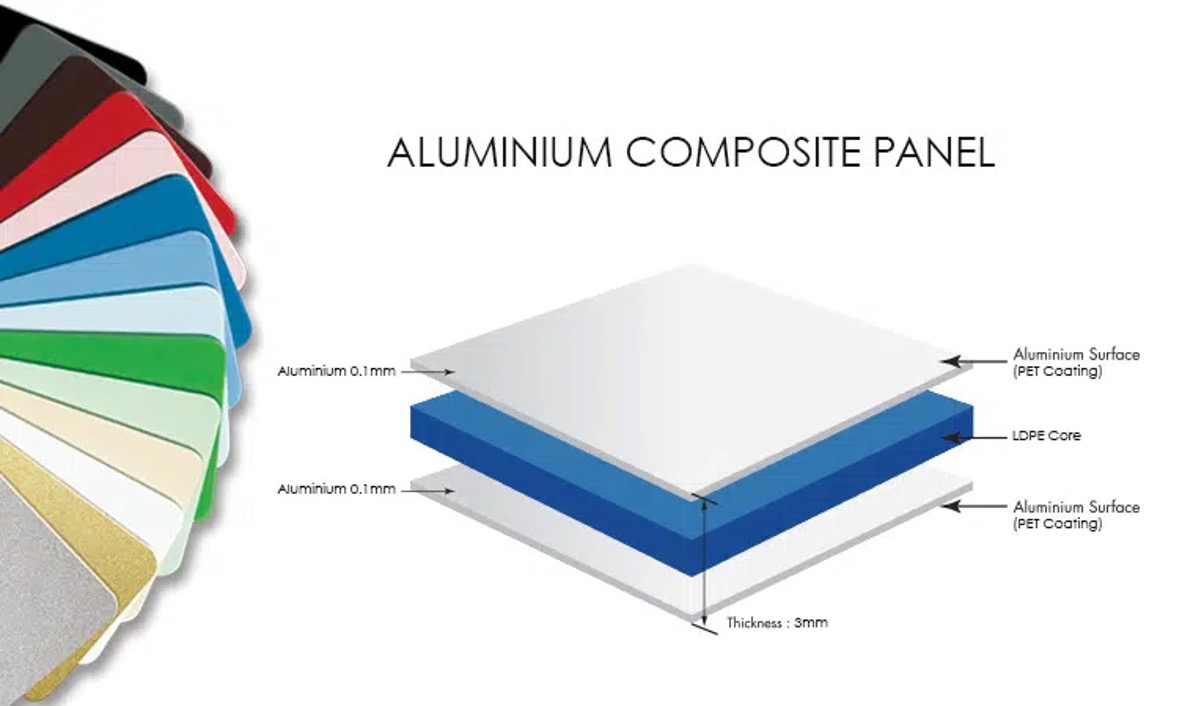

An aluminum composite panel (ACP), also known as aluminum composite material (ACM), is a form of sandwich panel made up of two outer layers of aluminum sheets and a core material sandwiched between them. The core material is usually polyethylene (PE) or a fire-retardant (FR) mineral-filled core.

The outside layers’ aluminum sheets provide strength, durability, and a visually appealing appearance, whereas the core material contributes stiffness and insulation. Adhesive or extrusion is used to bond the panels together.

Composite aluminum panels consist of several layers that contribute to their overall structure and properties. Specific details and characteristics of composite aluminum panels can vary between manufacturers and product lines. However, you can refer to some composite aluminum panel details below:

The panels feature two outer layers made of aluminum sheets. These aluminum layers provide strength, durability, and resistance to corrosion, weathering, and impact. They also contribute to the aesthetic appearance of the panels.

Sandwiched between the aluminum layers is the core material. The core is typically made of polyethylene (PE) or a fire-retardant (FR) mineral-filled core. The core adds rigidity, insulation, and stability to the panels.

To ensure the layers stay securely together, a strong bonding agent is used to join the aluminum sheets and the core material. Adhesive bonding or extrusion processes are commonly employed to create a firm bond.

These panels offer versatility in terms of colors and textures. They can be manufactured in a wide array of colors, including solid colors, metallic finishes, and patterns. Various textures can be applied to simulate the appearance of other materials such as wood, stone, or metal.

Composite aluminum panels can be coated or finished with various materials to enhance their appearance, performance, and protection. Coatings can include polyester, fluoropolymer (PVDF), or other specialized coatings that provide weather resistance, UV protection, and color retention.

Composite aluminum panels are available in a range of sizes and thicknesses to meet different project requirements. The thickness of the panels can vary from a few millimeters to several centimeters, depending on the desired strength and insulation properties.

Some composite aluminum panels are designed with fire-retardant cores to improve their fire resistance. These panels undergo testing and certification to ensure compliance with fire safety regulations.

Composite aluminum panels often come with specialized installation systems that facilitate easy and efficient installation. These systems can include interlocking mechanisms, concealed fasteners, or cladding systems, making the installation process more streamlined.

Aluminum composite metal panels (ACM) find diverse applications across multiple industries due to their exceptional qualities and versatility. One primary application is in building facades, where ACM panels are extensively utilized to create visually appealing and durable exteriors for commercial, residential, and institutional structures. The sleek and modern appearance of ACM panels enhances the aesthetic appeal of buildings while offering excellent weather resistance.

In the signage industry, ACM panels are favored for their ability to create eye-catching and long-lasting signs. The smooth surface of the panels provides an ideal canvas for printing graphics, logos, and text, making them suitable for both outdoor and indoor signage applications. ACM panels offer durability and color retention, ensuring that signage remains vibrant and impactful over time.

ACM panels are also commonly used for interior wall cladding. In commercial spaces such as offices, hotels, airports, and shopping malls, they contribute to the overall design aesthetic while providing a durable and easily maintainable surface. The lightweight nature of ACM panels makes them easy to install and handle during interior wall installations.

Partition walls and room dividers benefit from the versatility of ACM panels. The panels offer privacy, sound insulation, and a sleek appearance. They can be incorporated into office spaces, conference rooms, and residential areas to create functional and visually appealing divisions.

ACM panels are often employed to cover structural columns, providing a uniform and aesthetically pleasing appearance. By using ACM column covers, the overall design of a building can be enhanced, and the columns seamlessly integrated into the architectural vision.

Canopies and awnings benefit from the lightweight and flexible nature of ACM panels. These panels can be shaped and curved to fit the desired design, offering shade and protection from the elements. ACM panels are commonly employed in the construction of canopies and awnings for various applications, including entrances, walkways, and outdoor seating areas.

ACM panels are also utilized for ceilings and soffits, both indoors and outdoors. They provide a clean and modern look, creating a smooth and uniform surface. ACM panels can be easily integrated with lighting fixtures and other architectural elements to enhance the overall aesthetic appeal of the space.

In the exhibition and display industry, ACM panels offer a lightweight and portable solution for constructing stands, trade show booths, and displays. They can be easily assembled and disassembled, providing flexibility and convenience for showcasing products or services.

Beyond the architectural realm, ACM panels find applications in the transportation industry, such as constructing vehicle bodies, trailers, and interior paneling in buses, trains, and airplanes. The lightweight yet durable nature of ACM panels makes them an excellent choice for enhancing fuel efficiency and structural integrity in transportation vehicles.

In industrial settings, ACM panels are utilized for equipment enclosures, machine housings, and protective barriers. They offer a combination of strength, durability, and corrosion resistance, making them well-suited for demanding industrial environments.

In summary, aluminum composite metal panels (ACM) have a broad range of applications across industries. From building facades to signage, interior cladding to transportation, and industrial applications, ACM panels provide versatility, durability, and aesthetic appeal. Their lightweight nature, weather resistance, and ease of installation make them a popular choice for architects, designers, and engineers seeking reliable and visually appealing solutions.

Installing aluminum composite panels usually entails the following steps:

Always refer to the manufacturer’s specific installation instructions and guidelines for the composite aluminum panel system being used. Additionally, comply with local building codes and regulations and consult with professionals or experts if needed to ensure proper installation.

Installing aluminum composite panels costs $35-$60 per square foot, including materials and installation. However, the cost of ACM panels varies depending on the core type, color and finish, panel size, project complexity, panel size, and structural characteristics. ACM fire-retardant panels are more expensive than panels with PE cores. Adding a custom color, texture, or company logo to an ACM panel raises the overall cost. The width, length, and thickness of the aluminum composite panel all have an impact on construction and transportation costs, v.v.

In conclusion, composite aluminum panels open up a whole new world of architectural and creative possibilities. Their vast range of applications, from building facades to interior cladding, make them an adaptable option for any project. Using the installation tips offered, you can ensure a smooth and effective installation, maximizing the benefits of solar panels. Understanding the aspects that determine composite aluminum panel pricing allows you to make informed judgments while staying within budget. By realizing the potential of composite aluminum panels, you may transform areas, improve aesthetics, and build long-lasting, sustainable, and visually appealing structures. Accept the flexibility and limitless possibilities that composite aluminum panels bring to your designs.

EXPLORE MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com