Learn about the qualities, applications, and market forecast of cold rolled steel coils. This detailed reference explains the fundamental qualities and benefits of cold rolled steel coils in detail. Investigate their numerous applications in areas such as automobile, construction, and appliances. Learn more about the market dynamics, trends, and prospects for cold rolled steel coils. Whether you’re a steel industry specialist or looking for high-quality materials for your projects, this article provides a quick overview of the knowledge and market insights available in this enlightening resource.

Cold-rolled steel coils are steel products that have undergone a cold rolling process. Cold rolling is a manufacturing process in which hot-rolled steel is passed through rollers at room temperature, compressing and shaping it into thinner and more precise coils.

During cold rolling, the hot-rolled steel is first pickled to remove any scale or impurities on the surface. It is then passed through a series of rollers that apply pressure, reducing the thickness of the steel and improving its surface finish. This process also increases the strength and hardness of the steel.

Cold-rolled steel coils have several advantages over hot-rolled steel. They exhibit better dimensional accuracy, a smoother surface, and improved mechanical properties. The cold rolling process allows for tighter tolerances and the production of thinner gauges of steel. Cold-rolled steel coils find applications in various industries, including automotive, construction, appliances, and manufacturing, where precise dimensions, excellent surface quality, and consistent mechanical properties are required.

Prime cold-rolled steel coils find a wide range of applications across various industries. Here are some common applications of prime cold-rolled steel coils:

Automotive Manufacturing: Prime cold-rolled steel coils are extensively used in the automotive industry for producing body panels, chassis components, seat frames, suspension parts, reinforcements, and exhaust systems. The excellent surface finish, dimensional accuracy, and strength of cold-rolled steel make it ideal for these applications.

Appliances: Cold-rolled steel coils are widely employed in the manufacturing of appliances such as refrigerators, washing machines, dishwashers, and ovens. They are used for creating the outer panels, shelves, and internal components. Cold-rolled steel offers durability, corrosion resistance, and a sleek appearance.

Construction: Prime cold-rolled steel coils are utilized in the construction industry for various applications. They are used in the production of roofing materials, wall panels, structural components, doors, and window frames. The strength, formability, and dimensional accuracy of cold-rolled steel make it suitable for these construction purposes.

Furniture and Shelving: Cold-rolled steel coils are commonly used in the manufacturing of furniture, including desks, tables, chairs, and cabinets. They are also employed in the production of shelving units and storage systems. Cold-rolled steel offers stability, strength, and an attractive surface finish for furniture applications.

Pipes and Tubes: Prime cold-rolled steel coils are used in the production of pipes and tubes for various industries, including plumbing, construction, and infrastructure. Cold-rolled steel ensures dimensional accuracy, tight tolerances, and excellent surface quality, making it suitable for pipe manufacturing.

Electrical Equipment: Cold-rolled steel coils find applications in the electrical industry for manufacturing electrical enclosures, cabinets, and components. The high precision, formability, and surface finish of cold-rolled steel make it suitable for housing electrical equipment.

Packaging: Cold-rolled steel coils are employed in the production of packaging materials such as cans, drums, and containers. Cold-rolled steel provides strength, durability, and resistance to corrosion, ensuring the protection and preservation of packaged goods.

These are just a few examples of the many applications of prime cold-rolled steel coils. The versatility, dimensional accuracy, and excellent surface finish of cold-rolled steel make it a preferred choice for a wide range of industries and products.

The primary distinction between hot-rolled and cold-rolled steel coils is in the manufacturing process and the resulting steel characteristics. Here are the key distinctions:

Hot Rolled: Hot-rolled steel coils have a rougher surface finish due to the scaling that occurs during the heating process. They typically have an oxide layer or mill scale on the surface, which may require additional surface treatments.

Cold Rolled: Cold-rolled steel coils have a smoother and more refined surface finish. The cold rolling process eliminates the mill scale and produces a clean surface that is suitable for various applications without the need for additional treatments.

Hot Rolled: Hot-rolled steel coils have lower strength and hardness compared to cold-rolled steel. They are generally more ductile and have a higher tolerance for deformation.

Cold Rolled: Cold-rolled steel coils exhibit higher strength and hardness due to the strain hardening that occurs during the cold rolling process. They offer improved dimensional accuracy and precise mechanical properties.

Hot Rolled: Hot-rolled steel coils are produced by heating the steel above its recrystallization temperature and passing it through rollers at high temperatures. This process allows for quick shaping and forming of the steel, resulting in larger thicknesses and a scaled surface finish.

Cold Rolled: Cold-rolled steel coils are manufactured by subjecting hot-rolled steel through a cold rolling process. The steel is passed through rollers at room temperature, which compresses and shapes it into thinner gauges. This process provides tighter tolerances, improved surface finish, and higher strength.

Hot Rolled: Hot-rolled steel coils have looser dimensional tolerances compared to cold-rolled steel. This is because the steel is shaped and formed at high temperatures, which allows for greater variations in dimensions.

Cold Rolled: Cold-rolled steel coils have tighter dimensional tolerances, ensuring more precise thickness, width, and length measurements. The cold rolling process provides better control over thickness consistency.

Hot Rolled: Hot-rolled steel coils are commonly used in applications where the emphasis is on shaping and forming, such as structural components, pipes, and railroad tracks.

Cold Rolled: Cold-rolled steel coils are preferred for applications that require precise dimensions, excellent surface finish, and higher strength, such as automotive body panels, appliances, and construction materials.

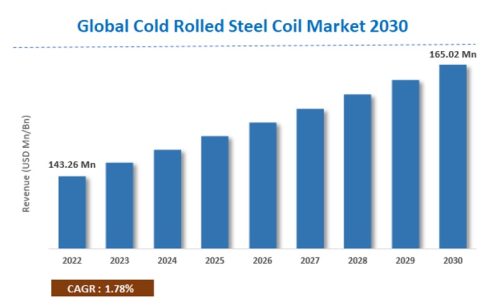

The global cold-rolled steel coil price was worth approximately USD 143.26 million in 2022 and is expected to increase to approximately USD 165.02 million by 2030, with a compound annual growth rate (CAGR) of approximately 1.78% between 2023 and 2030.

The worldwide cold-rolled steel coil market is expected to expand as demand for such steel products rises in construction and infrastructure development projects. This is especially evident in emerging economies that are substantially investing in national or regional infrastructure development. They are also supported by the large and growing participation of the private sector, which plays an important role in construction and building operations. These economies rely on high-quality steel and other components to construct world-class architecture, and cold-rolled steel coils can supply this need efficiently.

Furthermore, the expansion of the industrial sector in both developing and developed countries may boost the cold-rolled steel coil business further due to their use in the manufacture of appliances, machinery, and equipment. Rapid industrialization has increased demand for high-quality building and manufacturing materials, influencing the market’s growth trajectory. Rising population and rapid urbanization, combined with shifting consumer consumption patterns, have resulted in increased investment in the development of power plants and transportation networks. All of these activities necessitate high-quality steel with good characteristics, resulting in a preference for cold-rolled steel coil.

One of the most significant growth barriers in the worldwide cold rolled steel coil market is trade protectionism, which includes import and tariff limitations. Such policies may disrupt supply networks while also raising production costs and limiting enterprises’ market access. Furthermore, the advent of substitute materials, as well as continuous research to produce more efficient alternatives to steel in all forms, may impede growth. Other issues, such as supply chain disruption and an economic recession, are projected to hinder the market’s expansion rate.

The Harmonized System (HS) code for cold-rolled steel coils may vary depending on the specific characteristics and country of origin. However, a commonly used HS code for cold-rolled steel coils is 72091690, which represents “Flat-rolled products of iron or non-alloy steel, of a width of 600 mm or more, cold-rolled (cold-reduced), not clad, plated or coated”.

Regarding the price of cold-rolled steel coils, it can fluctuate based on various factors such as market demand, raw material costs, production capacity, and regional dynamics. Additionally, prices can vary depending on the specific specifications, quantities, and quality requirements of the coils.

While it is challenging to definitively rank the top 5 cold-rolled steel coil companies, considering factors such as market share, production capacity, and global presence, the following companies are widely recognized as major players in the industry:

ArcelorMittal: ArcelorMittal is the world’s largest steel producer, with a global footprint and a diverse range of steel products. They have a significant presence in the cold-rolled steel coil market, serving various industries worldwide.

POSCO: POSCO is a leading steel company based in South Korea. They have a strong reputation for producing high-quality cold-rolled steel coils and are known for their technological advancements and customer-focused approach.

Nippon Steel Corporation: Nippon Steel Corporation, headquartered in Japan, is a prominent steel producer with a wide range of steel products. They have a strong presence in the cold-rolled steel coil market and are known for their innovation and reliability.

Baosteel: Baosteel, based in China, is one of the largest steel producers in the world. They offer a diverse range of steel products, including cold-rolled steel coils, and have a strong presence in both domestic and international markets.

Tata Steel: Tata Steel, headquartered in India, is a global steel company with a strong presence in the cold-rolled steel coil market. They are known for their high-quality products, customer-centric approach, and commitment to sustainability.

In conclusion, this in-depth exploration of cold rolled steel coils has provided valuable insights into their properties, applications, and market forecast. We have delved into the key characteristics and advantages of cold rolled steel coils, showcasing their versatility and wide range of uses in various industries. By understanding their properties and applications, professionals and businesses can make informed decisions regarding material selection for their projects. Additionally, our analysis of the market forecast has shed light on the prospects and trends on cold rolled steel coils. Armed with these insights, stakeholders can navigate the market with confidence and leverage the benefits of cold rolled steel coils in their respective fields.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com