Look no further for information on the extraordinary qualities of billet 6061. This instructive guide will take you through the various capabilities of billet 6061 aluminum alloy. Discover why this material is widely valued in a variety of industries, from its outstanding strength to its vast range of applications.

Aluminum 6061, also known as aluminum grade 6061, is a type of aluminum alloy composed of aluminum billet and elements such as magnesium, silicon, copper, manganese, zinc, chromium, and others. As a result, 6061 aluminum has the properties of being easy to shape and weld, as well as having strong corrosion resistance.

Furthermore, 6061 aluminum is manufactured in a variety of shapes such as bars and rods, with each type having a range of widths and thicknesses for versatile application in a wide range of projects and structures.

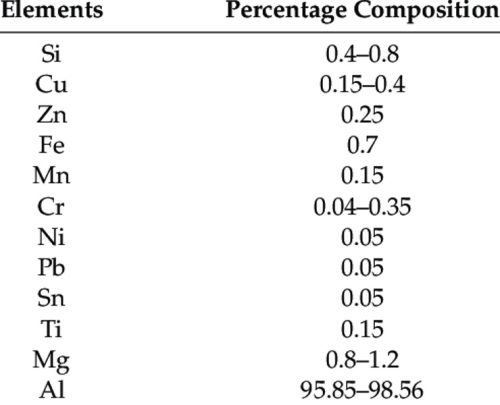

The following is the composition of 6061 aluminum profile: Unit%

With the aforesaid composition, 6061 billet aluminum has the following excellent properties and benefits:

Aluminum 6061 billet is classified into four different grades: billet 6061-T0 aluminum, billet 6061-T4 aluminum, billet 6061-T5 aluminum, and billet 6061-T6 aluminum. Each variety is made from a separate 6061 aluminum fabrication method and has a variable hardness. As an example:

| Type of billet aluminum | Production process |

| 6061-T0 | Lower strength temperatures are obtained by annealing. |

| 6061-T4 | T4 solution that has been heat treated and organically aged. |

| 6061-T5 | Quenched as a result of advanced shaping and age. |

| 6061-T6 | T6 solution that has been heat treated and artificially aged. |

Because of the various manufacturing processes, each type of billet 6061 aluminum will have its distinct advantages.

Billet 6061-T0 aluminum: A product that is organically aged and cooled by air following the extrusion and shaping process.

Billet 6061-T4 aluminum: A product that is promptly cooled with water following extrusion and profile shaping.

Billet 6061-T5 aluminum: This product has been cooled and artificially aged for around 4 hours before being cooled with air, resulting in a product with a relatively high hardness.

Billet 6061-T6 aluminum: It is a product that is both heat treated and subjected to an artificial aging process, resulting in a product with better hardness, bending strength, and maximum extension rate than other varieties, and it is the most commonly used in the aluminum 6061 line.

Aluminum 6061 T6 is the most commonly utilized product in the 6061 aluminum series.

When selecting an aluminum alloy for a project, examine the properties required for the ultimate use, such as strength, corrosion resistance, conductivity, or a combination of these traits. 6061 aluminum and 7075 aluminum are two typical alloys worth comparing in the business.

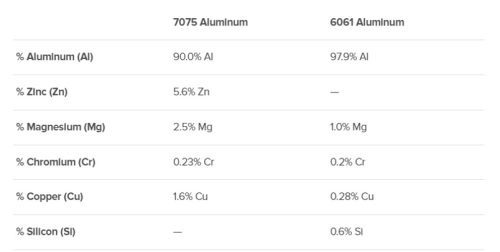

The initial distinction between 6061 and 7075 aluminum can be deduced from their names. Aluminum 6061 is a member of the 6000 alloy series. This class’s major alloy components are silicon and magnesium. 7075 aluminum alloy, on the other hand, is a member of the 7000 class. As a result, the principal alloying elements are zinc and copper. The table below compares the chemical compositions of 7075 aluminum and 6061 aluminum.

Yielding power

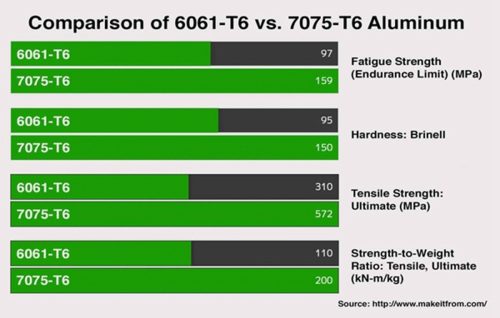

The yield strength of 7075 aluminum alloy is greater than that of 6061 aluminum. As a result, 7075 aluminum can bear additional pressure and impact without deformation. The chemical composition and heat treatment of 7075 aluminum contribute to its yield strength. However, with a yield strength of 276MPa, 6061 aluminum is not fully brittle.

Electrical resistance

Aluminum 7075 and 6061 both have low electrical resistivity, which means they are good electrical conductors. As a result, these alloys are suited for electrical applications. However, the electrical resistivity of 6061 aluminum is lower than that of 7075 aluminum. As a result, it conducts electricity better than 7075 aluminum.

Temperature conductivity

Aluminum alloys are often good heat conductors. However, the thermal conductivity of 7075 aluminum varies from that of 6061 aluminum. This is due to their chemical compositions and heat treatment as well. The thermal conductivity of 6061 aluminum is somewhat higher than that of 7075 aluminum. As a result, it is a good choice in heat exchangers when heat dissipation is the key need.

Elasticity

Elasticity helps you understand the resilience and deformation resistance of materials. It is also related to the stiffness of the material. Both 7075 and 6061 aluminum respond similarly to elastic deformation.

Material toughness

The hardness of a substance determines its ability to withstand deformation caused by indentation, penetration, or other causes. Both alloys are tough enough to withstand pressure without cracking or deforming. 7075 aluminum, on the other hand, is tougher than 6061 aluminum.

Temperature tolerance

We compare the melting points of 7075 t6 and 6061 t6 to determine their temperature resistance. The melting temperature of 7075 aluminum is 477 – 635°C, which is slightly lower than the melting point of 6061 aluminum, which is 582 – 652°C. As a result, 6061 alloy can endure higher temperatures than 7075 alloy. It should be noted, however, that 7075 aluminum has an outstanding heat treatment reaction. It also provides for significantly better element distribution in the metal.

Corrosion protection

6061 aluminum alloy is more corrosion resistant than 7075 aluminum alloy. The rationale behind this is not implausible. The copper content of the 7075 alloy is significantly higher than that of the 6061 alloy. Corrosion is unavoidable since copper reacts more with the environment.

Considerations for Fabrication

When it comes to fabrication, 6061 aluminum alloy outperforms 7075 aluminum alloy. This is frequently owing to the 6061 alloy’s reduced hardness and tensile strength. Its decreased hardness makes machining easier, and its lower tensile strength assures better formability. Both materials can be joined by soldering, brazing, or adhesives. 6061 aluminum, on the other hand, is weldable, whereas 7075 aluminum is not.

While not as formable or weldable as other aluminum alloys, 7075 aluminum excels in high-stress applications where strength is critical. 7075 aluminum is sometimes referred to as “aircraft grade” since it is one of the strongest aluminum alloys available. It is commonly found in airplanes, missiles, spacecraft, and other military uses. It also appears in various wear-prone elements, structural materials, and military applications.

6061 aluminum appears in a wide range of all-purpose applications due to its adaptability, workability, strength, corrosion resistance, and joinability, including structural materials, welded assemblies, pipes, fasteners, electronic parts, and more. It is widely employed in a variety of industries and applications.

6061 billet aluminum is commonly found in:

There is no set price for 6061 aluminum because the price is determined by a variety of factors such as:

Domestic demand for aluminum is currently expanding, accompanied by increasingly stringent client requirements. Stavian Metal Company has consistently upgraded production techniques and technology to supply consumers with thousands of goods that meet domestic and international quality standards.

We hope that the information provided above has helped you comprehend what billet 6061 aluminum is. This aluminum line has several exceptional characteristics and is widely employed in a variety of fields.

If you have any questions or require help about Stavian’s aluminum products, please contact us using the details below.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com