Understanding the impact of zinc addition for brass is crucial for manufacturers seeking to optimize the mechanical and chemical properties of this widely used alloy. At Stavian Industrial Metal, we specialize in providing high-quality zinc tailored to the specific needs of brass production, ensuring enhanced strength, corrosion resistance, and workability. With our deep expertise and commitment to precision, we support industries in achieving consistent alloy compositions that meet both performance standards and regulatory requirements.

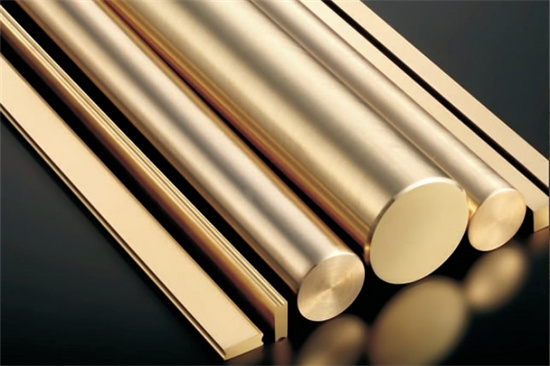

Zinc plays a foundational role in the formulation of brass, influencing the alloy’s physical, chemical, and mechanical properties. Brass, a binary alloy primarily composed of copper and zinc, exhibits a wide range of characteristics depending on the percentage of zinc added. Typically, zinc content in brass ranges from 5% to 45%, and each level of addition significantly alters the performance and behavior of the alloy.

A low zinc addition for brass, often between 5% and 20%, results in what is referred to as “”red brass.”” This type of brass maintains a high copper content, offering excellent corrosion resistance, good machinability, and a visually appealing reddish hue. As the zinc content increases, the alloy becomes stronger and harder but less ductile. In contrast, high-zinc brasses, such as those with 35% to 45% zinc, are stronger, more cost-effective, and better suited for applications requiring rigidity and wear resistance, such as plumbing fixtures or industrial fittings.

Moreover, zinc enhances brass’s resistance to dezincification—a form of corrosion that selectively removes zinc from the alloy—when balanced properly with other elements like tin or arsenic. This makes zinc a strategic component in ensuring both durability and longevity of the final brass product.

Learn more: What Is Unprocessed Zinc Ingot? Key Facts, Uses & Supply

The mechanical performance of brass varies significantly with different levels of zinc addition. As zinc content increases, the alloy transitions from a soft, ductile material to a stronger and harder one. This transformation is especially important in applications requiring precise performance specifications.

Understanding the mechanical influence of zinc is crucial in material selection, especially for industries such as automotive, electrical, and construction, where specific strength and processing characteristics are essential.

Corrosion resistance is a vital factor in brass applications, particularly in marine, plumbing, and architectural environments. Zinc, while beneficial in many respects, also introduces complexities in corrosion behavior.

When zinc content is maintained below 20%, brass exhibits excellent resistance to atmospheric and aqueous corrosion. This makes low-zinc brasses ideal for outdoor fixtures, naval hardware, and components in humid conditions. However, as the zinc content increases, the risk of dezincification rises—especially in environments rich in chlorides or sulfates.

To counteract this, modern brass formulations include small additions of tin, phosphorus, or arsenic, which help stabilize the microstructure and prevent selective leaching of zinc. Furthermore, proper heat treatment and alloy homogenization processes are critical in enhancing the corrosion resistance of high-zinc brasses.

In summary, zinc addition must be optimized carefully. While it improves mechanical strength and cost-efficiency, it necessitates attention to corrosion mitigation strategies to ensure long-term reliability in service environments.

Learn more: Aluminum-Zinc Alloy-Coated Steel – Advantages, Disadvantages, Discounted Price List

Brass is frequently chosen for electrical components, and understanding how zinc affects conductivity is crucial in these applications. The addition of zinc to copper significantly alters its electrical and thermal performance.

Copper, known for its excellent conductivity, begins to lose this characteristic with increasing zinc content. For instance, pure copper has an electrical conductivity of about 100% IACS (International Annealed Copper Standard), but with a 30% zinc addition for brass, conductivity drops to around 28%-30% IACS. While this reduction is substantial, the remaining conductivity is still sufficient for applications like electrical connectors, terminals, and switchgear components where structural integrity is equally important.

Thermal conductivity follows a similar trend. Lower zinc content brass retains higher thermal conductivity, beneficial for heat exchanger components and plumbing systems where thermal transfer is important. For applications prioritizing conductivity over strength, designers often select low-zinc brasses or copper alloys with alternative additives.

Balancing electrical and thermal performance with mechanical strength remains a key consideration when specifying zinc levels in brass for electrical and thermal applications.

The flexibility of zinc addition for brass allows manufacturers to tailor alloy compositions to suit a wide array of industrial applications. The specific use of a brass alloy depends largely on its zinc content and the resulting combination of mechanical, thermal, and corrosion-resistance properties.

In plumbing and sanitary applications, high-zinc brass (typically 35% to 40% zinc) is favored for its strength, machinability, and relatively low cost. These brasses are used in fittings, valves, and faucets, where structural integrity and wear resistance are vital. Some of these alloys also include small additions of lead for improved machinability.

For decorative and architectural applications, low-zinc brass (5% to 20% zinc) is preferred due to its warm golden hue and excellent resistance to tarnishing. Items such as door handles, railings, and ornamental hardware utilize these alloys not just for appearance, but also for their formability and corrosion performance.

In electrical and electronic components, moderate-zinc brasses (20% to 30% zinc) strike a balance between conductivity and strength. Terminal connectors, pins, and grounding components benefit from these properties. The alloys are easy to stamp or machine, ensuring efficient mass production.

In musical instruments, especially wind instruments like trumpets and saxophones, specific brass grades with controlled zinc content provide the required acoustic properties, strength, and aesthetic appeal.

Understanding the interplay between zinc percentage and brass performance helps engineers and procurement specialists make informed material choices for their projects.

From a metallurgical perspective, zinc addition for brass influences both phase structure and processing characteristics. The phase diagram of the copper-zinc system reveals critical insights into how varying zinc levels affect the solidification and mechanical behavior of brass.

Brass with up to 35% zinc primarily exists in the alpha phase, characterized by a single solid solution of zinc in copper. This phase is highly ductile and easy to work, ideal for cold-forming operations such as rolling, drawing, and spinning. As zinc content rises above 35%, the alloy enters a dual-phase region (alpha + beta), where the beta phase contributes to increased strength and hardness but reduces ductility.

Alpha-beta brasses, while more challenging to form, respond well to hot working techniques like forging and extrusion. Their structure allows for a combination of strength and manufacturability, making them suitable for industrial components that must endure significant mechanical stress.

In casting operations, high-zinc brass provides excellent fluidity, ensuring precision in die-cast parts. However, attention must be given to controlling gas porosity and grain structure through optimized casting temperatures and cooling rates.

Metallurgical control is crucial in ensuring consistent properties and minimizing defects. Understanding the relationship between zinc levels and phase composition is essential for producing reliable and high-performance brass components.

In today’s sustainability-driven manufacturing landscape, the use of zinc in brass offers notable environmental and economic advantages. Zinc is not only abundant and recyclable but also contributes to cost-efficient alloy design.

Zinc addition for brass helps lower the total cost of the alloy by reducing the amount of copper, which is generally more expensive. This makes brass more accessible for a variety of industries without compromising essential performance characteristics. Manufacturers benefit from reduced raw material costs while maintaining product quality.

From an environmental standpoint, both copper and zinc are highly recyclable. Brass scrap is routinely collected and remelted with minimal degradation of properties. The efficient recyclability of zinc-containing brass contributes to circular economy initiatives, lowering the environmental footprint of the final product.

Furthermore, advances in refining and smelting technologies now allow for better control over zinc recovery and emissions, aligning brass production with stricter environmental regulations. This supports manufacturers in meeting ESG (Environmental, Social, and Governance) targets while still utilizing the functional advantages that zinc brings to brass.

Stavian Industrial Metal is committed to delivering eco-conscious, high-performance metal solutions, and the strategic use of zinc in brass aligns with these values.

Ensuring consistent zinc addition for brass requires robust quality control processes and adherence to international material standards. As the percentage of zinc directly affects alloy performance, even small deviations can lead to product failures or non-compliance with industry requirements.

Brass manufacturers follow precise alloy specifications such as ASTM B16 for free-cutting brass, ASTM B124 for copper and copper-alloy forging rod, and EN 12164 for brass rod for machining. These standards dictate not only the allowable range of zinc but also the limits for impurities and other alloying elements like lead, tin, or iron.

At Stavian Industrial Metal, quality assurance is implemented at every stage of production—from raw material inspection and alloy formulation to melting, casting, and final testing. Advanced spectroscopy and metallographic analysis are employed to verify composition and microstructure, ensuring that the brass meets both customer requirements and regulatory guidelines.

Traceability is also maintained through detailed production records and batch tracking, which is crucial for sectors like aerospace, defense, and electronics, where reliability and documentation are paramount.

With a combination of technical expertise and strict quality protocols, manufacturers can deliver brass components that perform reliably across demanding applications.

As industries push for higher performance materials and more sustainable solutions, the future of zinc addition for brass is shaped by innovation in alloy development and processing technologies.

One emerging trend is the development of lead-free brass alloys, driven by environmental regulations such as RoHS (Restriction of Hazardous Substances) and NSF standards for drinking water systems. These newer alloys rely heavily on optimized zinc additions, along with elements like silicon or bismuth, to maintain machinability without compromising safety or performance.

Another area of research is the nano-engineering of brass surfaces. By manipulating the zinc content and surface treatments at the micro- and nano-scale, manufacturers are developing brass components with superior wear resistance, antibacterial properties, and even improved conductivity for niche electronics.

Additive manufacturing (3D printing) using brass powders with controlled zinc content is also opening new possibilities for complex, custom-designed parts with minimal waste. These innovations could revolutionize the way industries approach both prototyping and production with brass materials.

As a supplier at the forefront of metallurgical innovation, Stavian Industrial Metal continues to invest in R&D and strategic partnerships to deliver next-generation brass alloys that meet evolving industrial challenges.

For more information

Understanding Galvanizing Zinc: Process, Benefits, and Applications

Special High Grade Zinc: Properties, Uses and Market Outlook

High-Precision Die Casting Zinc Alloy Solutions for Industry

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com