Discover the properties, characteristics, and advantages of Q235 carbon steel in this comprehensive guide. Learn about its composition and understand how the carbon content influences its performance. Explore the mechanical properties, including hardness and tensile strength, that make Q235 steel suitable for structural applications. Uncover its excellent weldability, formability, and machinability, allowing for efficient fabrication processes. Gain insights into the cost-effectiveness and wide availability of Q235 carbon steel, making it a popular choice in various industries. Whether you’re involved in construction, manufacturing, or general steel applications, this article provides a concise overview of Q235 steel‘s key features and benefits.

Q235 steel is a popular carbon structural steel in China, similar to ASTM A36 in the United States and S235JR in Europe. It is distinguished by its low carbon content (0.22% maximum) and reasonably high tensile strength (370-500 MPa). Q235 steel has excellent weldability, machinability, and formability, making it popular in general structural applications such as buildings, bridges, and machines. It is often used to make steel plates, pipelines, and sections. Furthermore, Q235 steel is frequently utilized as a raw material in galvanized steel and other coated steel products.

Q235 carbon steel exhibits several characteristics that contribute to its widespread use in various applications. Here are some key characteristics of Q235 steel:

Low Carbon Content: Q235 steel has a carbon content of less than 0.22%, which contributes to its excellent weldability and formability. The low carbon content also reduces the risk of brittleness during fabrication and improves the overall ductility of the material.

High Tensile Strength: Q235 steel exhibits a relatively high tensile strength, typically ranging from 370 to 500 MPa. This high strength allows it to withstand heavy loads and makes it suitable for structural applications.

Good Ductility and Toughness: Q235 steel demonstrates good ductility, meaning it can be stretched or bent without breaking. It also exhibits good toughness, which enables it to absorb energy and resist fracture under impact or dynamic loading conditions.

Excellent Weldability: Q235 steel is highly weldable and can be easily joined through various welding methods, including arc welding, resistance welding, and gas welding. It forms strong and reliable welds, allowing for efficient fabrication and construction.

Versatility: Q235 steel is versatile and finds wide-ranging applications. It is commonly used in structural components such as beams, columns, and trusses in buildings and bridges. It is also used for manufacturing machinery, automotive parts, and general-purpose steel products.

Corrosion Resistance: While Q235 steel is not inherently corrosion-resistant, it can be protected from corrosion through coatings, such as paint or galvanizing. Galvanized Q235 steel, for example, is coated with a layer of zinc, providing enhanced corrosion resistance.

Q235 Hardness: Q235 steel has a moderate hardness, which contributes to its machinability. It can be easily cut, drilled, and machined using common tools and techniques.

Cost-Effective: Q235 steel is cost-effective compared to many other types of steel, making it popular for various projects and applications. Its availability and affordability contribute to its widespread use in construction and manufacturing industries.

It’s important to note that the specific characteristics and performance of Q235 steel can vary based on factors such as heat treatment, processing methods, and the presence of impurities. Therefore, it is advisable to consult the relevant specifications and standards for precise information regarding the specific grade and application requirements.

Q235 steel has numerous essential qualities that make it widely used in a variety of applications. The following are the key qualities of Q235 steel:

The density of Q235 steel is around 7.85 g/cm³.

Q235 steel has a melting point of around 1420-1460°C.

Tensile Strength: The tensile strength of Q235 steel normally ranges between 370 and 500 MPa.

Q235 steel’s minimum yield strength is 235 MPa.

Elongation: The elongation at break for Q235 steel is usually approximately 26%.

According to China’s national standard GB/T 700, Q235 steel has the following chemical composition (in mass percentages):

Carbon (C): <0.22%.

Silicon (Si): <0.35%.

Manganese (Mn): <1.40%.

Phosphorus (P): <0.035%.

Sulfur (S): <0.045%.

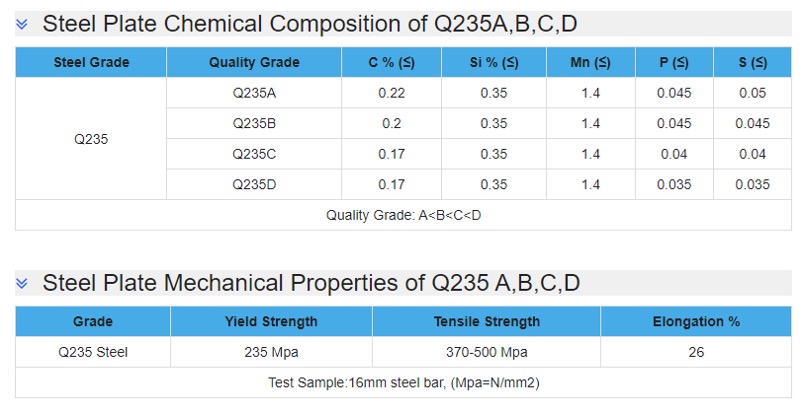

According to the GB/T 700-2006 standard, carbon structural steel Q235 is classified into four categories based on metallurgical quality: A, B, C, and D. The chemical makeup of Q235A, B, C, and D differs. The sulfur concentration of A, B, C, and D declines sequentially, while the phosphorus content of A and B is the same, followed by that of C, and the phosphorus level of D is the lowest. Different grades of Q235A, Q235B, Q235C, and Q235D correspond to different impact temperatures. A indicates no influence, B is greater than 20 degrees, C is greater than 0 degrees, and D is greater than -20 degrees.

To better understand the chemical composition and physical properties of Q235 steel grades, please refer to the table below:

Q235 steel has strong weldability and may be easily welded using conventional techniques such as arc, resistance, and gas welding. This feature enables the manufacture and joining of Q235 steel components.

Q235 steel has excellent ductility, allowing for plastic deformation without fracture. This characteristic enables easy shaping, forming, and bending during industrial processes.

Q235 steel has strong machinability, making it suitable for typical machining operations such cutting, drilling, and milling.

While Q235 steel is not inherently corrosion-resistant, it can be protected from corrosion through various methods, such as applying coatings or using galvanized or stainless steel versions of Q235.

It is crucial to note that the particular properties of Q235 steel can change depending on heat treatment, manufacturing procedures, and material variances. As a result, it is best to check the necessary specifications and standards for precise and detailed property information for specific applications.

Q235 steel offers several outstanding advantages that contribute to its popularity and widespread use in various applications. Here are some of its notable advantages:

Q235 steel is known for its cost-effectiveness. It is readily available and widely produced, which helps keep its price relatively low compared to other types of steel. This makes it an attractive option for projects with budget constraints.

Q235 steel exhibits excellent weldability, which is a significant advantage in many applications. It can be easily welded using various techniques, such as arc welding, resistance welding, and gas welding. This allows for efficient fabrication and construction, reducing assembly time and costs.

Q235 steel is highly versatile and finds extensive use in different industries and applications. It is commonly employed in construction for structural components like beams, columns, and trusses. It is also used in manufacturing machinery, automotive parts, pipelines, and general-purpose steel products. The versatility of Q235 steel makes it suitable for a wide range of projects.

Q235 steel possesses a relatively high tensile strength, typically ranging from 370 to 500 MPa. This high strength enables it to withstand heavy loads and provides structural stability. It is particularly beneficial in applications that require strength and load-bearing capacity, such as building structures and bridges.

Q235 steel exhibits good ductility, allowing it to undergo significant plastic deformation without fracturing. This property makes it easy to shape, form, and bend during manufacturing processes, enabling flexibility in design and fabrication. It can be readily molded into various shapes and sizes according to project requirements.

Q235 steel is widely available and commonly produced in large quantities. This ensures a stable supply chain and reduces lead times for projects. Its abundant availability makes it accessible to a wide range of industries and facilitates its use in different geographical regions.

Q235 steel is a standardized grade in China, with equivalent counterparts in other international standards such as ASTM A36 (United States) and S235JR (Europe). This standardization ensures consistent properties and facilitates easy comparison and substitution across different regions, simplifying international trade and cooperation.

Q235 steel has good machinability, meaning it can be easily machined and processed using standard machining techniques. It can be cut, drilled, and milled efficiently, which contributes to streamlined manufacturing processes and enhanced productivity.

These outstanding advantages make Q235 steel a popular choice in various applications, offering a balance of affordability, performance, and ease of use. However, it’s important to consider specific project requirements and consult relevant specifications and standards to ensure the suitability of Q235 steel for a particular application.

To summarize, Q235 carbon steel has a number of traits, characteristics, and advantages that make it a popular material in a variety of industries. Its composition, with a low carbon concentration, allows for outstanding weldability and formability, resulting in efficient fabrication operations. Q235 steel has a high tensile strength, making it ideal for structural applications that require load bearing capacity. Its good machinability enables simple processing and modification. Furthermore, Q235 carbon steel is inexpensive and widely available, making it an appealing option for projects with limited budgets. With its unique combination of qualities and benefits, Q235 steel remains a popular material for a variety of applications, demonstrating its adaptability and dependability.

Learn more

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com