A solid block or mass of iron that has been cast into a standardized shape for ease of handling, storage, and transportation is known as an iron ingot. It is a prevalent kind of iron processing and trading in the industrial sector. So, how are iron ingots created? Learn more about it with Stavian in the article below.

Read more: What exactly is steel bar billet?

Any quantity of metal specifically cast from a molten state of known composition, shape, weight, and physical dimension is referred to as an ingot. This consistency is designed to aid in the accounting of metal quantities cast, stored, or transported. A wide range of metals, including gold, silver, platinum, and tin, are often cast into ingot form. Ingot designs come in a wide range of forms and sizes, which are determined by the finished product’s intended purpose and metallurgical requirements.

Metals have been cast into defined shapes for as long as metallurgy has existed. From the ancient Chinese sycee to the Roman Empire’s gold, silver, and lead ingots, the ingot was a widely acknowledged manner of displaying valuable metals for storage and transportation. The practice of casting metals into standardized forms is still practiced today, with the vast majority of metal goods beginning as ingots. The accounting and logistical benefits of generating products of homogeneous character are the primary motivators for the practice. Each ingot is a mass of metal with a specified composition, size, form, and weight, allowing for convenient recordkeeping, storage, and transportation.

Iron ingots are iron ingots that have been formed into a precise shape that makes them easy to carry and store. Casting is the technique of pouring molten metal into a mold to form a hardened shape. Ingots are formed of iron and are typically rectangular or cylindrical in shape. Depending on the metal and the manufacturing process, the size of an ingot can range from a few ounces to several tons.

In the iron and steel industry, the term “dark iron” refers to iron that has not undergone any final processing or treatment. It is a raw form of iron, not refined or processed into steel or other iron and steel products.

Dark iron ingot often has a high carbon concentration and contains impurities like silicon, sulfur, and phosphorus. It is collected from the production of raw iron (pig iron) in blast furnaces for smelting of iron ore. The dark iron ingot is easily meltable and ductile but unsuitable for direct use in end applications.

Dark iron ingot often has to go through refining and processing processes to convert into steel or other iron and steel products. This process involves removing impurities and adjusting the chemical composition of the iron to achieve the desired properties and characteristics.

In short, dark iron ingot in the iron and steel industry is iron that has not undergone any final processing or treatment, which needs to undergo refining and processing processes to convert into iron or steel products.

Iron ingots may have a code that represents the heat or lot number. This code identifies the specific batch or melt from which the ingot originated. It helps track and trace the material’s properties, manufacturing conditions, and quality control information.

The code on an iron ingot may indicate the specific grade or specification of the material. Different grades of iron or steel have varying chemical compositions, mechanical properties, and intended uses. The code can provide information about the material’s characteristics and compliance with industry standards.

The code might include the manufacturer’s identification, such as a logo, company name, or unique identifier. This helps identify the producer of the iron ingot and provides information about the source and origin of the product.

The code may include details about the size, dimensions, or weight of the iron ingot. This information helps in inventory management, logistics, and material planning.

It’s important to note that the specific coding system and format can vary between different companies, industries, or regions. Therefore, the interpretation of the code on an iron ingot would depend on the specific context and the standards followed by the manufacturer or industry.

The manufacturing process of iron ingots typically involves the following steps:

Inside the blast furnace, a combination of coke (carbon-rich fuel), limestone (flux), and hot air is introduced. The coke acts as a reducing agent, reacting with the oxygen in the iron ore to produce carbon monoxide. The carbon monoxide then reacts with the iron oxides, reducing them to molten iron (pig iron) and carbon dioxide.

Pig iron

It’s worth noting that the above steps describe a simplified overview of the iron ingot manufacturing process. In industrial-scale iron production, additional steps such as hot rolling, forging, or further refining may be involved to produce various iron and steel products with specific properties and shapes.

The cooling of a molten liquid (known as the melt) in a mold produces ingots. The production of ingots serves numerous purposes.

To begin, the mold is designed to completely solidify and generate an adequate grain structure required for later processing, as the structure formed by the cooling of the melt regulates the material’s physical qualities.

Second, the mold’s shape and dimensions are intended to facilitate ingot handling and downstream processing. Finally, the mold is designed to reduce melt waste and improve ingot ejection, as losing either melt or ingot raises finished product manufacturing costs.

The mold can be designed in a variety of ways to suit the physical qualities of the liquid melt and the solidification process. Molds can be fluted or flat walled, and can be used for top, horizontal, or bottom-up pouring. Because of the increased contact area, the fluted shape improves heat transfer. Molds can be solid “massive” design, sand cast (for pig iron, for example), or water-cooled shells, depending on heat transfer needs. Ingot molds are tapered to reduce cracking caused by uneven cooling. A fracture or void forms when a liquid to solid transition causes a volume shift for a constant mass of material. The creation of these ingot flaws may render the cast ingot worthless, necessitating its re-melting, recycling, or disposal.

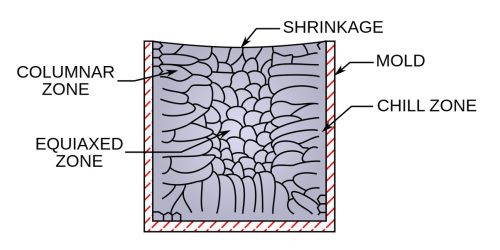

The process of cooling and precipitation of the molten metal greatly influences the physical structure of a crystalline substance. Depending on the liquid being chilled and the cooling rate of the mold, metal in contact with the ingot walls rapidly cools and develops either a columnar structure or a “chill zone” of equiaxed dendrites during the pouring process.

As the liquid cools within the mold, differential volume effects cause the top of the liquid to retreat, producing a curved surface at the mold top that may later need to be machined from the ingot for a top-poured ingot. The mold cooling effect creates an advancing solidification front with several associated zones: a solid zone closer to the wall that draws heat from the solidifying melt, a “mushy” zone for alloys that is the result of solid-liquid equilibrium regions in the alloy’s phase diagram, and a liquid region. The velocity of front advancement determines how long dendrites or nuclei must grow in the solidification area. The breadth of the mushy zone in an alloy can be modified by altering the liquid melt alloy compositions or tuning the heat transmission qualities of the mold.

There are also continuous casting methods for ingot processing, in which a stationary front of solidification is generated by the constant take-off of cooled solid material and the addition of a molten liquid to the casting process.

In the United States, over 70% of aluminum ingots are cast utilizing the direct cold casting process, which lowers cracking. Because of stress-induced cracks and butt deformation, 5% of ingots must be destroyed.

In summary, the molds employed for this purpose are more than just vessels for cooling molten metal. The physical properties of the completed ingot will be determined at the atomic level by how the molds are built. The distribution of alloy additives, gasses, and contaminants during cooling, which is largely governed by mold design, determines the crystalline structure and integrity of the completed product. Mold designs are thus developed to generate an ingot that is not only physically feasible but also metallurgically compatible with its intended ultimate usage. These factors will determine the shape, inner surface, and size of the mold, as well as the location of the filing access.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com