In this post, you will discover the versatility of the aluminum extrusion 20×20 profile. This standardized square cross-section offers a unique combination of strength, lightweight, and corrosion resistance, making it a popular choice across industries. Learn about the benefits, such as its suitability for indoor and outdoor use, and potential drawbacks to consider. With detailed dimensions, material properties, and CAD model availability, this guide equips you to integrate the aluminum extrusion 20×20 into your next project, whether it’s industrial, architectural, or DIY. Unlock the full potential of this versatile aluminum profile for your needs.

Aluminum extrusion 20×20 refers to a square-shaped aluminum profile with precise dimensions of 20 millimeters (mm) in width and 20 mm in height. This standardized size is a common and widely used aluminum extrusion product, offering a perfect square cross-section that provides structural integrity and design flexibility.

Manufactured through the specialized aluminum extrusion process, the 20×20 aluminum extrusion profile leverages the inherent benefits of aluminum, including lightweight, corrosion resistance, and high strength-to-weight ratio. The square shape and standardized dimensions allow for easy integration into a wide range of applications and compatibility with various accessories and joining methods.

Widely available from numerous manufacturers and suppliers, this versatile aluminum extrusion size is a popular choice across diverse industries, from construction and machinery to furniture and DIY projects. Its standardization and customization potential make it a go-to solution for engineers, designers, and hobbyists seeking to harness the power of aluminum extrusion.

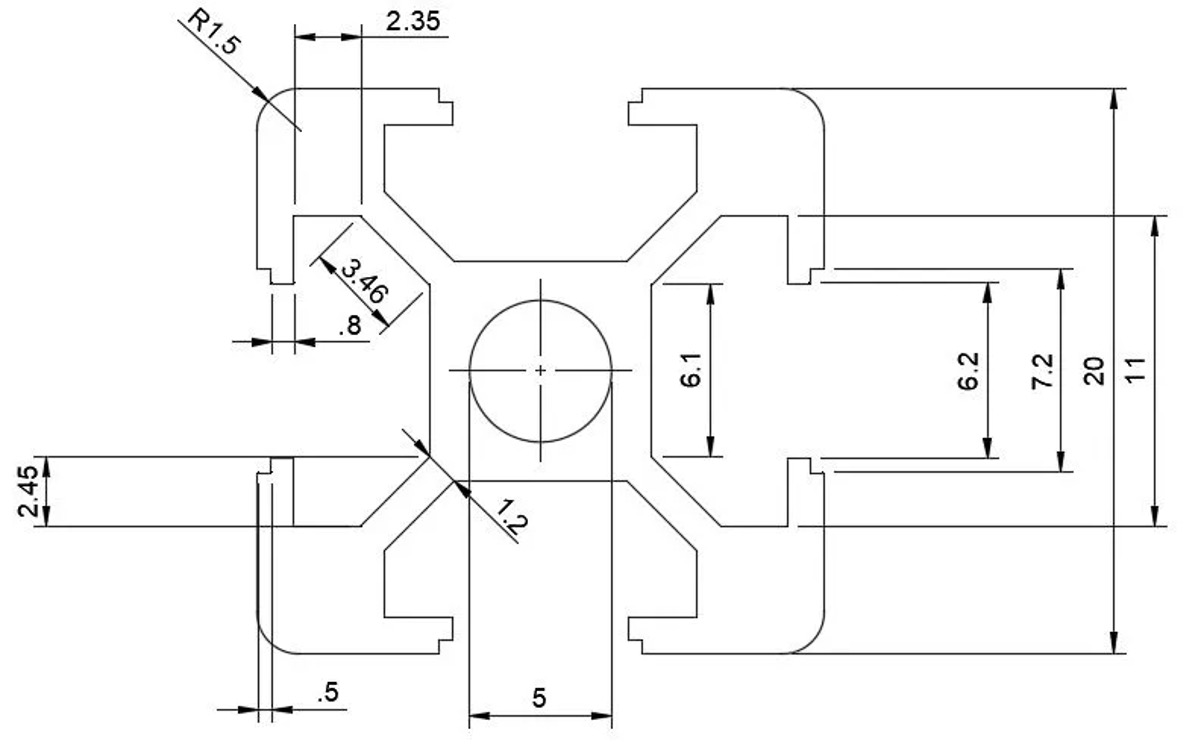

The dimensions of a standard 20×20 aluminum extrusion are as follows:

To break this down further:

This standardized 20×20 mm square profile is a widely used size in the aluminum extrusion industry, offering a range of benefits, however, everything always has both benefits and drawbacks.

Let’s explore the key benefits and potential drawbacks of using aluminum extrusion 20×20:

Structural Integrity:

Lightweight:

Corrosion Resistance:

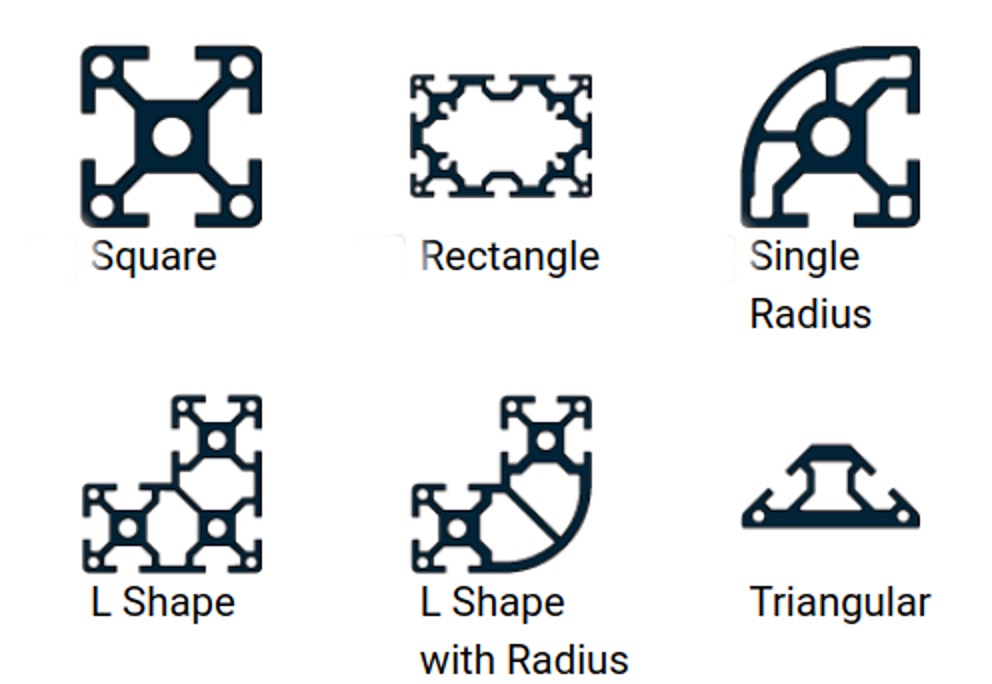

Design Flexibility:

Ease of Fabrication and Assembly:

Limited Load-Bearing Capacity:

Cost Considerations:

Potential for Deformation:

Surface Finish Limitations:

Overall, the benefits of 20×20 aluminum extrusion, including its structural integrity, lightweight, and corrosion resistance, often outweigh the potential drawbacks, making it a widely used and versatile solution across various industries and applications.

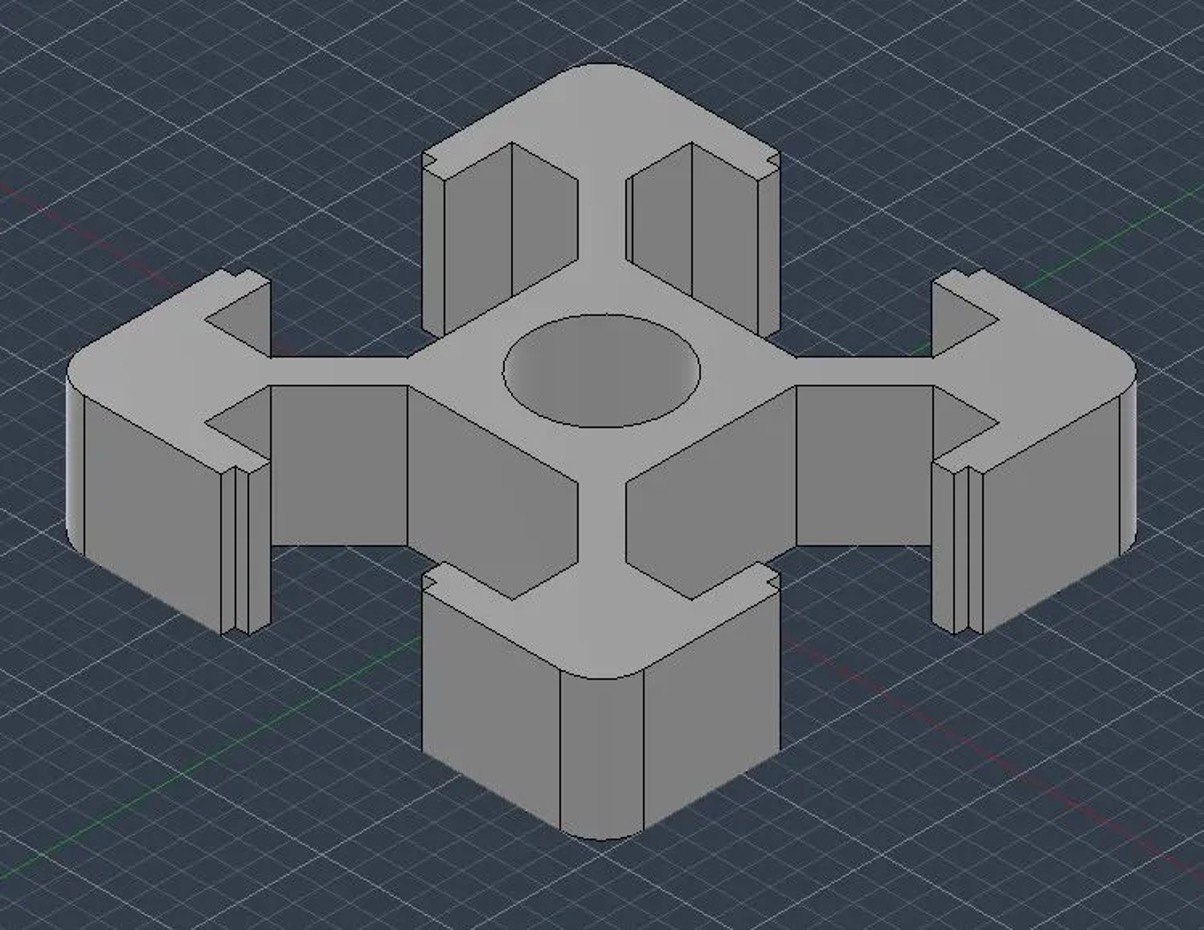

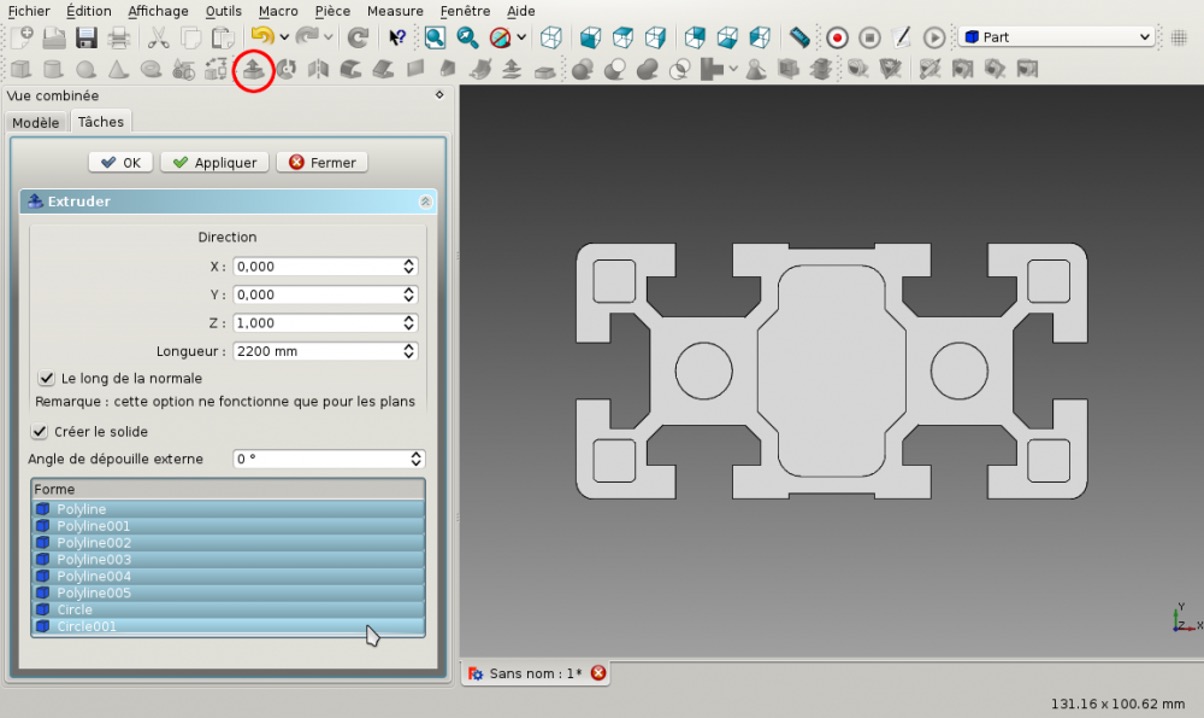

Here’s some information on 20×20 aluminum extrusion CAD models:

CAD Models for 20×20 Aluminum Extrusion:

Engineers, designers, and 3D modelers often create CAD (Computer-Aided Design) models of 20×20 aluminum extrusions to incorporate them into their digital designs and product development workflows. These CAD models typically include the following characteristics:

The CAD model accurately represents the standard 20mm x 20mm square cross-section of the aluminum extrusion.

The wall thickness is typically modeled between 1.5mm to 2.5mm, depending on the specific application and manufacturer.

The CAD model incorporates the standard dimensional tolerance of ±0.2mm to match the real-world specifications of the 20×20 aluminum extrusion.

In addition to the basic square profile, CAD models may include variations with additional features, such as mounting holes, grooves, or custom shapes.

These profiles allow designers to explore and incorporate the extrusion’s versatility into their designs.

The CAD model can be assigned the material properties of the specific aluminum alloy used, such as 6063 or 6061, to accurately represent the mechanical and physical characteristics.

CAD models can be used to create realistic renderings and visualizations of the 20×20 aluminum extrusion within the overall product or assembly.

This helps designers and engineers evaluate the aesthetic and functional integration of the extrusion into their designs.

Many aluminum extrusion manufacturers and suppliers provide downloadable CAD models of their standard profiles, including the 20×20 size, on their websites or through online CAD libraries.

These ready-to-use CAD models can be directly imported into various 3D modeling and CAD software, such as AutoCAD, SolidWorks, Inventor, and CATIA, streamlining the design process.

Using CAD models of 20×20 aluminum extrusions allows designers, engineers, and architects to accurately incorporate this versatile profile into their digital designs, facilitating efficient product development, assembly planning, and visualization.

The aluminum extrusion 20×20 emerges as a highly adaptable and desirable choice for a wide range of applications. Its combination of structural integrity, lightweight, and corrosion resistance makes it a standout among aluminum profiles. While there are some limitations, such as load-bearing capacity and cost considerations, the inherent benefits often outweigh these drawbacks. As designers, engineers, and DIY enthusiasts explore the versatility of this square profile, the possibilities for innovative use cases continue to expand. Whether in industrial, architectural, or custom projects, the aluminum extrusion 20×20 offers a versatile and reliable solution that can elevate the performance and aesthetics of any endeavor. Its widespread appeal is a testament to its enduring value.

EXPLORE MORE

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com