Choosing the right zinc casting material is crucial for manufacturers aiming to achieve durability, precision, and cost-effectiveness in their production processes. At Stavian Industrial Metal, we understand that each application—from automotive components to consumer electronics—demands specific mechanical and thermal properties. Our extensive experience in non-ferrous metals enables us to offer tailored solutions that meet international standards while optimizing efficiency. Whether you’re seeking corrosion resistance, high fluidity, or superior dimensional stability, our zinc alloys are engineered to support a wide range of casting techniques including die casting and gravity casting. Partner with us to ensure your production lines benefit from consistent quality, reliable supply chains, and expert technical support.

Zinc casting material is widely valued for its versatility, mechanical strength, and cost-efficiency across industrial applications. As a non-ferrous metal alloy, zinc is primarily used in pressure die casting due to its excellent castability, dimensional stability, and surface finish. It melts at a relatively low temperature (approximately 419.5°C), which not only makes it energy-efficient for manufacturing but also extends the life of molds and tooling equipment.

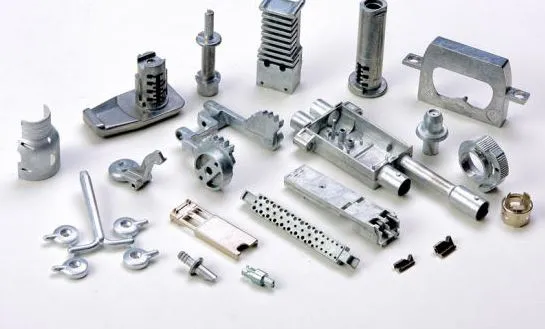

One of the key attributes of zinc casting material is its ability to form complex and thin-walled components with minimal post-processing. This material exhibits high tensile strength, excellent ductility, and resistance to wear and corrosion, especially when alloyed with elements like aluminum, magnesium, or copper. Zinc die cast parts are often favored in applications where precision, aesthetic appeal, and durability are critical.

Industries such as automotive, electronics, and hardware benefit greatly from the consistency and functionality of zinc alloys. These materials support tight tolerances, rapid production cycles, and seamless integration with surface treatments such as plating or painting. In addition, their recyclability aligns with increasing demands for sustainable manufacturing practices.

Learn more: Explore Zinc Bar: Uses, Benefits & Industrial Applications

The selection of the appropriate zinc alloy can significantly influence the performance and longevity of the final product. Different alloy compositions are tailored to meet specific mechanical and chemical requirements.

Zamak alloys are the most commonly used zinc casting materials in die casting processes. Zamak is a family of alloys comprising zinc with small amounts of aluminum, magnesium, and copper, designed to enhance strength and corrosion resistance.

These alloys are particularly effective in producing intricate components with fine details and thin walls, making them ideal for the electronics and consumer goods industries.

ZA alloys (Zinc-Aluminum) represent another class of zinc casting material with higher aluminum content than Zamak alloys. These are generally used in gravity casting rather than die casting.

ZA alloys are known for their excellent bearing properties, impact strength, and suitability for structural components in automotive and industrial applications.

Learn more: Zinc Block: Industrial Applications, Protection Systems, and Engineering Insights

Zinc casting material plays a crucial role in various sectors due to its adaptability and high performance in both aesthetic and structural roles. Manufacturers favor zinc for its ability to deliver high-quality parts at scale, especially when precision and durability are required.

In the automotive sector, zinc alloys are commonly used for parts that require intricate geometries and superior surface finishes. These include:

Zinc casting material provides the necessary strength while keeping the component lightweight and corrosion-resistant. Moreover, the material’s ability to dampen vibrations contributes to improved noise and ride comfort in vehicles.

Zinc die casting is also prevalent in the production of housings, connectors, and internal components for consumer electronics. The benefits include:

These features make zinc ideal for smartphones, laptops, small kitchen appliances, and other everyday gadgets where both aesthetics and functionality matter.

Zinc casting material offers a range of advantages that make it a preferred choice for high-volume production and precision engineering. Its properties align well with the demands of modern manufacturing, helping companies optimize performance, reduce costs, and improve sustainability.

Zinc alloys provide outstanding dimensional accuracy, which is essential for parts that must fit precisely into assemblies. This allows for reduced machining and post-processing, saving both time and labor. The material also supports tight tolerances and sharp detail replication, making it ideal for decorative and functional parts alike.

Additionally, zinc casting material delivers a smooth, high-quality surface finish that can be further enhanced through plating, painting, or powder coating. This aesthetic advantage is crucial for visible parts in consumer products and automotive trim, where visual appeal is critical.

Zinc melts at a relatively low temperature compared to other metals like aluminum or magnesium, which significantly reduces energy consumption during the casting process. This low melting point also extends the life of dies and molds, minimizing tooling replacement costs.

Manufacturers benefit from fast cycle times, as zinc alloys cool and solidify quickly. This enables high-volume production with consistent quality, making zinc casting material a cost-effective solution for mass manufacturing environments.

When selecting materials for casting, manufacturers often compare zinc with alternatives such as aluminum, magnesium, or plastic. Each material has its strengths, but zinc offers a compelling balance of performance, processability, and cost.

These comparisons highlight the competitive edge of zinc casting material for industries prioritizing longevity, performance, and visual quality in their components.

With increasing emphasis on sustainable manufacturing, zinc casting material stands out for its environmentally friendly characteristics. Zinc is one of the most recyclable metals in the world, and its recycling process requires significantly less energy than primary metal production.

These factors contribute to a lower environmental footprint, helping manufacturers meet regulatory requirements and sustainability goals while maintaining product quality.

Selecting the appropriate zinc alloy and casting method involves evaluating several technical and economic factors. A thorough understanding of the application’s requirements ensures optimal performance and cost-effectiveness.

If the component has intricate geometry or thin walls, a zinc alloy with excellent fluidity such as Zamak 3 or ZA-8 may be most suitable. For structural parts requiring high strength and hardness, ZA-12 or Zamak 5 could be better options.

Considerations include:

High-volume production benefits significantly from the longevity of zinc casting dies and the short cycle times of hot chamber die casting. The initial tooling investment may be higher than plastic molding, but the cost per part is lower in large runs due to reduced downtime and scrap rates.

By aligning the alloy selection and casting technique with production goals, manufacturers can achieve both quality and efficiency in their operations. At Stavian Industrial Metal, our experts assist clients in selecting the ideal zinc casting material based on detailed performance criteria and production parameters.

For more information

Professional Aluminum Billet Casting Service for Precision Manufacturing

Understanding Galvanizing Zinc: Process, Benefits, and Applications

Special High Grade Zinc: Properties, Uses and Market Outlook

High-Precision Die Casting Zinc Alloy Solutions for Industry

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com