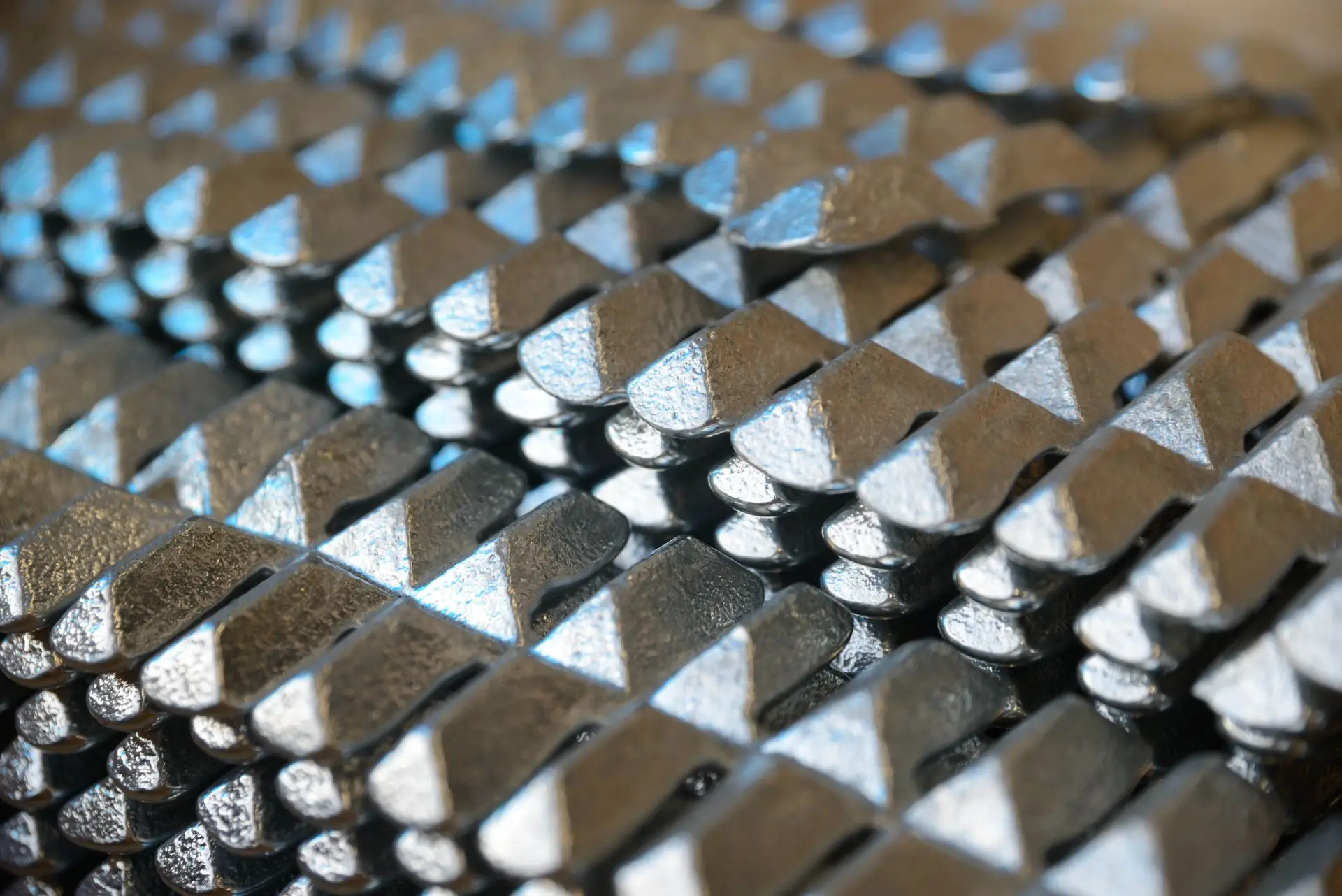

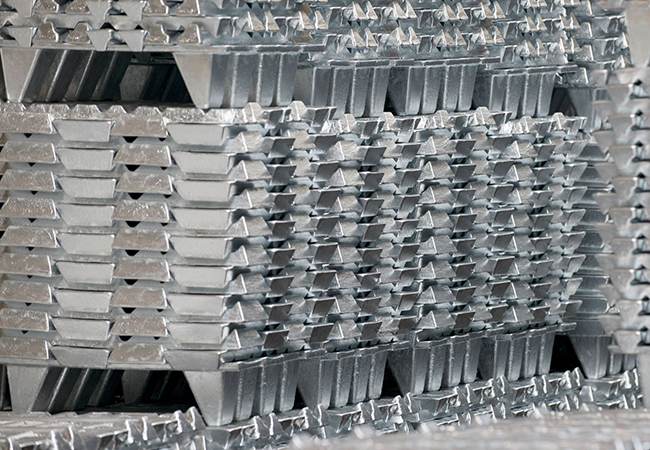

Zamak alloy is a high-performance zinc-based material widely used across various industries due to its exceptional castability, strength, and resistance to corrosion. As a trusted supplier in the global non-ferrous metals market, Stavian Industrial Metal delivers premium-quality Zamak alloy solutions tailored to meet the demanding standards of automotive, electronics, hardware, and consumer goods manufacturing. With a consistent composition and excellent surface finish, our Zamak alloy supports intricate designs and high-volume production, ensuring both durability and cost efficiency. Backed by advanced supply chain capabilities and a commitment to sustainability, Stavian Industrial Metal is your reliable partner for sourcing Zamak alloy with precision and reliability.

Zamak alloy is a family of zinc-based alloys with the addition of aluminum, magnesium, and copper, engineered to offer superior mechanical properties and excellent castability. These alloys are predominantly used in die casting processes due to their low melting point, smooth surface finish, and dimensional stability. Zamak stands for Zinc, Aluminium, MAgnesium, and Kupfer (German for copper), reflecting its core composition.

The primary advantage of Zamak alloy lies in its versatility. Unlike pure zinc or other metal alternatives, Zamak provides an ideal balance between strength and ductility. This makes it a preferred material in industries such as automotive, electronics, furniture, and consumer goods. In addition, its ability to replicate fine details in molds makes it highly suitable for decorative items, intricate parts, and components requiring tight tolerances.

Moreover, Zamak alloy supports high-speed production with minimal secondary processing. Its thermal and electrical conductivity, combined with excellent corrosion resistance, further enhances its suitability for industrial applications. In many use cases, Zamak replaces more expensive materials like brass or stainless steel without compromising performance.

Zamak alloy is not a single composition but rather a group of standardized alloys, each tailored for specific needs. The most commonly used grades are Zamak 2, Zamak 3, Zamak 5, and Zamak 7.

Understanding these differences helps engineers and product designers select the optimal material for their applications. While Zamak 3 serves as the default, Zamak 5 and 2 offer enhanced mechanical properties for demanding environments.

In addition to the standard grades, Zamak alloy can be customized or combined with other materials to meet specific requirements. For example, modified Zamak formulations with enhanced corrosion resistance or improved surface finish are available for niche applications such as marine environments or luxury product components.

These specialty variants allow manufacturers to tailor properties like tensile strength, elongation, and thermal expansion to precise needs. At Stavian Industrial Metal, we provide technical support for custom alloy development, ensuring our clients receive materials that align perfectly with their production goals.

Zamak alloy is recognized for its performance efficiency and economic advantages across multiple sectors. Here are the key benefits that make it a go-to choice for many manufacturers:

These benefits allow Zamak alloy to replace more expensive metals in many applications, providing similar performance at a lower cost.

In the automotive industry, Zamak alloy is widely used for both functional and aesthetic components. Its dimensional stability and mechanical strength make it suitable for producing door handles, mirror housings, emblems, fuel system parts, and HVAC control components.

One of the primary reasons Zamak is preferred in automotive applications is its ability to produce lightweight yet durable parts that maintain performance under vibration and temperature fluctuations. Additionally, its excellent finishing properties allow for plating, painting, or coating, which meets both safety and branding requirements.

Cost efficiency is another factor. Compared to aluminum or brass, Zamak offers similar mechanical properties at a lower material and processing cost, helping manufacturers manage budgets without sacrificing quality.

Zamak alloy is equally prominent in the electronics sector, where compactness and heat dissipation are critical. The alloy’s thermal conductivity and shielding properties make it an excellent material for enclosures, connectors, and frames.

Electronics often require components that maintain tight tolerances and resist corrosion over time. Zamak meets these criteria while allowing for high-speed die casting, which supports large-scale production. Its ability to integrate with other components—such as plastic or rubber inserts—also enhances design flexibility.

At Stavian Industrial Metal, we provide certified Zamak alloy materials tailored to the requirements of electronic component manufacturers, ensuring consistent quality and compliance with industry standards.

As global industries move toward sustainable manufacturing, Zamak alloy presents a compelling advantage due to its recyclability and environmentally friendly properties. Composed primarily of zinc, which can be recycled indefinitely without significant degradation, Zamak fits perfectly into circular economy models.

Manufacturing with Zamak alloy also results in minimal material waste. The high yield during die casting and low melting temperature reduce energy usage compared to metals like steel or aluminum. These efficiency gains contribute to lower carbon footprints across the production cycle. Moreover, Zamak does not produce harmful by-products, making it safer for workers and more compliant with environmental regulations.

At Stavian Industrial Metal, we support green production by offering recycled Zamak alloy that meets rigorous quality standards. Our supply chain prioritizes eco-responsibility, helping customers meet their sustainability goals without compromising product performance or durability.

While Zamak alloy offers numerous benefits, certain challenges must be managed to fully leverage its potential in manufacturing. These challenges often relate to material handling, casting parameters, and long-term durability in specific environments.

One key issue is susceptibility to creep at elevated temperatures. Zamak components used in high-heat settings may experience dimensional changes over time. To address this, engineers should design with appropriate safety factors or consider alloy variants with modified compositions that offer better thermal stability.

Another concern involves corrosion in high-humidity or salt-exposed environments. Although Zamak has good general corrosion resistance, additional surface treatments such as electroplating or powder coating are recommended for marine or outdoor applications.

Lastly, porosity during casting can affect the strength and finish of Zamak parts. This is often due to improper mold design or gas entrapment during the die casting process. Using vacuum die casting and optimizing injection speeds can help eliminate such defects and improve overall product integrity.

The smooth casting characteristics of Zamak alloy make it exceptionally receptive to a variety of surface finishing techniques, allowing manufacturers to achieve both aesthetic appeal and functional enhancements. Common surface treatments include:

These finishing options add both value and longevity to Zamak components. At Stavian Industrial Metal, we offer technical support for finishing process selection based on your specific product requirements.

Choosing the right material for manufacturing depends on a balance of cost, performance, and processing needs. Zamak alloy offers several advantages over traditional materials like aluminum, brass, and plastic.

By understanding these differences, manufacturers can make informed decisions based on application-specific needs. At Stavian Industrial Metal, we provide expert consultation to help clients determine the most efficient and effective material solution.

As a leading player in the industrial metals market, Stavian Industrial Metal provides a comprehensive solution for businesses seeking reliable access to high-quality Zamak alloy. Our global supply network ensures consistent delivery, while our quality assurance systems guarantee material performance that meets international standards.

We cater to a wide range of industries—including automotive, electronics, construction, and consumer goods—by offering:

Our commitment to customer satisfaction and sustainability sets us apart. Whether you’re developing a new product or scaling up production, Stavian Industrial Metal stands ready to support your goals with dependable materials and professional service.

The future of Zamak alloy lies in continued innovation, driven by evolving industrial demands and sustainability targets. Research is currently focused on improving the creep resistance and mechanical strength of Zamak without compromising its castability. This includes exploring micro-alloying techniques and enhancing grain structures through process optimization.

Another promising area is hybrid material development. Combining Zamak with polymers or other metals in multi-material assemblies can unlock new possibilities in lightweight design and cost reduction. Smart integration of Zamak components into electric vehicles and renewable energy systems is also gaining traction.

Digital tools such as AI-driven simulation and real-time quality monitoring are being used to refine die casting processes, ensuring fewer defects and higher consistency. At Stavian Industrial Metal, we invest in keeping up with these technological advancements to provide cutting-edge solutions to our clients.

With ongoing R&D and market adaptation, Zamak alloy will continue to be a cornerstone in the future of industrial design and production, offering manufacturers a sustainable and high-performance alternative across global supply chains.

For more information

Understanding Galvanizing Zinc: Process, Benefits, and Applications

Special High Grade Zinc: Properties, Uses and Market Outlook

High-Precision Die Casting Zinc Alloy Solutions for Industry

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com