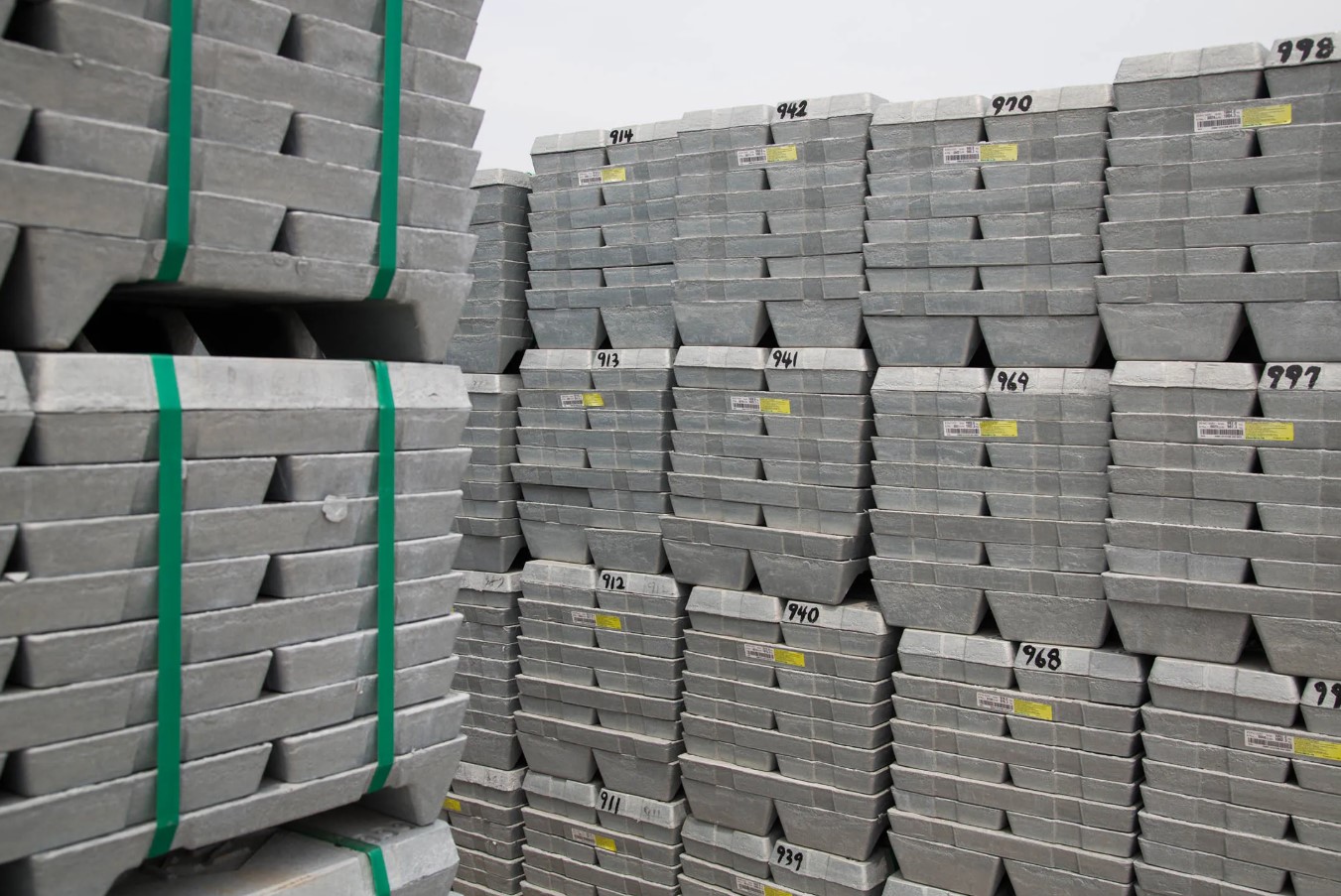

Refined zinc plays a crucial role in modern industry thanks to its high purity and versatile properties. As a trusted supplier, Stavian Industrial Metal provides refined zinc that meets international standards, ensuring excellent corrosion resistance, electrical conductivity, and surface finish for diverse applications such as galvanizing, die casting, and alloy production. With a strong commitment to quality and sustainability, we deliver consistent performance and reliable supply to support our global partners in manufacturing, construction, and energy sectors.

As Stavian Industrial Metal, we understand that refined zinc is defined by its exceptional purity, typically reaching 99.995% or higher depending on industrial standards such as SHG (Special High Grade). This high level of refinement ensures superior corrosion resistance, uniform mechanical behavior, and enhanced electrochemical performance. Refined zinc is primarily derived from zinc ore concentrates through a series of processes including roasting, leaching, purification, and electrolysis. Each stage plays a critical role in removing impurities like lead, cadmium, iron, and copper, resulting in a final product that exhibits excellent surface quality and consistent metallurgical stability. The purity and consistency of refined zinc directly influence its suitability for downstream applications in galvanizing, die casting, and the production of various zinc alloys used across manufacturing and construction industries.

Chemically, refined zinc is characterized by its dense crystalline structure and stable metallic bonding, allowing it to perform efficiently as a coating material. It has a relatively low melting point of around 419.5°C and a boiling point of 907°C, making it ideal for thermal applications and alloying processes. Furthermore, zinc’s amphoteric nature enables it to react with both acids and alkalis, contributing to its versatility in chemical and electrochemical industries. These characteristics form the foundation for its extensive use in corrosion protection and advanced material engineering.

The production of refined zinc begins with carefully selected zinc sulfide ores such as sphalerite, which contain varying proportions of zinc and other trace elements. Stavian Industrial Metal emphasizes strict quality control in sourcing raw materials, as impurities at this stage can significantly affect the efficiency of refining and the purity of the final product. Once mined, the ore undergoes crushing and grinding to achieve the appropriate particle size for subsequent processing.

During roasting, the zinc sulfide ore is heated in the presence of oxygen to convert it into zinc oxide while releasing sulfur dioxide gas. This oxidation stage is crucial for improving the extractability of zinc. The roasted oxide is then subjected to leaching with sulfuric acid to dissolve the zinc and separate it from insoluble residues. Through this process, zinc ions are transferred into a liquid solution, preparing them for purification and electrolysis.

Purification is achieved by adding chemical reagents to remove impurities such as copper, cadmium, and cobalt from the leach solution. The purified solution is then fed into electrolytic cells where zinc is deposited onto aluminum cathodes under controlled voltage and current conditions. The resulting zinc sheets are stripped from the cathodes and melted into ingots, forming the refined zinc product. This electrolytic method ensures high purity, excellent homogeneity, and minimal environmental impact compared to older pyrometallurgical methods.

One of the most important applications of refined zinc is in the galvanizing industry, where it serves as a protective coating for steel and iron. By forming a barrier against oxidation and creating a sacrificial anode effect, zinc prevents rust formation and extends the lifespan of metallic structures. Stavian Industrial Metal supplies refined zinc ingots that are specifically formulated for hot-dip and electro-galvanizing processes, offering superior adhesion and uniform coating thickness. These properties are vital in industries such as automotive, infrastructure, and energy, where durability and safety are paramount.

Refined zinc is a critical component in die casting due to its favorable melting characteristics and ability to produce intricate, high-precision parts. It is widely used in automotive components, electronic housings, and hardware fittings. When alloyed with elements like aluminum, magnesium, or copper, refined zinc forms high-strength materials that offer excellent dimensional stability and surface finish. At Stavian Industrial Metal, we supply refined zinc tailored to the needs of die casting manufacturers, ensuring optimal performance during the casting process and consistent mechanical properties in finished products.

Beyond metallurgical applications, refined zinc plays an essential role in the chemical industry as a reagent and catalyst. It is used in the production of zinc oxide, zinc sulfate, and other compounds that serve as raw materials for rubber, paint, and agricultural industries. In energy storage, refined zinc is utilized in the manufacture of zinc-carbon and zinc-air batteries, providing stable voltage and reliable power output. Its high electrochemical potential and recyclability make it a sustainable choice for next-generation battery technologies.

The demand for refined zinc continues to grow as industries transition toward sustainability and environmental responsibility. Zinc’s recyclability and long service life in protective coatings contribute significantly to reducing material waste and carbon emissions. For instance, galvanized steel structures often last for decades with minimal maintenance, lowering the overall environmental footprint of construction projects. At Stavian Industrial Metal, we are committed to promoting circular economy practices by supporting the recycling and reuse of zinc materials, ensuring that our products align with global green manufacturing standards.

In addition, advancements in zinc-based batteries and renewable energy applications highlight refined zinc’s importance in building a sustainable energy future. Zinc’s abundance and non-toxic nature make it a valuable alternative to other metals that pose environmental challenges. By investing in innovative refining technologies and responsible sourcing, we aim to enhance the efficiency, safety, and sustainability of refined zinc production for both current and future industrial needs.

The refined zinc market is influenced by global mining output, smelting capacities, and consumption patterns across industrial sectors. China remains the world’s largest producer and consumer of refined zinc, followed by countries such as South Korea, India, Canada, and Australia. These nations maintain advanced smelting facilities and established logistics networks to meet the increasing global demand. Stavian Industrial Metal plays an active role in this global ecosystem by supplying refined zinc that meets international standards for purity and performance, ensuring stable delivery to clients in Asia, Europe, and beyond.

The production landscape has evolved in recent years, with a growing emphasis on sustainability and energy-efficient refining technologies. Many producers have invested in electrolysis-based refining processes that reduce emissions while improving product consistency. Additionally, recycling has become an integral part of zinc production, as secondary zinc derived from scrap and residues now accounts for a significant portion of total global supply.

The demand for refined zinc is primarily driven by the galvanizing industry, which consumes over half of global production. Infrastructure expansion, construction, and the automotive sector continue to boost the need for corrosion-resistant steel. Emerging economies are investing heavily in transportation networks and urban development, creating long-term demand for refined zinc coatings.

In addition to galvanizing, the growing popularity of zinc-based batteries and renewable energy storage solutions is expected to reshape the market landscape. As more countries pursue carbon neutrality, the versatility of refined zinc in clean energy applications—such as zinc-air batteries—positions it as a key enabler of sustainable growth. Stavian Industrial Metal closely monitors these global trends to anticipate customer needs and deliver innovative, high-quality zinc products tailored to evolving market requirements.

Ensuring the quality and consistency of refined zinc is essential for maintaining its performance across various industrial uses. International standards such as ASTM B6 and ISO 752 define the chemical composition, permissible impurities, and physical properties required for refined zinc ingots. Typically, Special High Grade (SHG) refined zinc must contain at least 99.995% Zn with minimal traces of lead, iron, cadmium, and copper.

At Stavian Industrial Metal, every batch of refined zinc undergoes rigorous quality control procedures, including spectrographic analysis, microstructure examination, and surface inspection. Our laboratory facilities are equipped with advanced testing instruments to ensure compliance with both local and international specifications. The company’s focus on quality assurance enables our customers to rely on refined zinc products that deliver consistent performance in galvanizing, die casting, and chemical manufacturing processes.

The production of refined zinc has made significant strides toward environmental responsibility over the past decade. Modern refining plants are designed to minimize emissions, recycle process water, and recover valuable by-products such as sulfuric acid and cadmium. By integrating closed-loop systems, smelters can reduce waste and optimize resource efficiency.

Stavian Industrial Metal is committed to sustainable production practices. We collaborate with partners who adhere to strict environmental management standards, ensuring that every ton of refined zinc is produced with minimal ecological impact. Our focus includes reducing carbon intensity, improving energy efficiency, and supporting the use of renewable energy sources throughout the supply chain.

In addition, we actively support the global initiative for a circular zinc economy—where used zinc materials are collected, processed, and reintroduced into the production cycle. This approach not only conserves natural resources but also contributes to reducing greenhouse gas emissions, aligning with international goals for a low-carbon future.

Partnering with Stavian Industrial Metal provides businesses with access to high-grade refined zinc that is optimized for industrial efficiency and sustainability. Our refined zinc products offer several key advantages:

Consistent purity: With SHG-grade quality, our zinc maintains stable chemical composition and low impurity levels suitable for galvanizing, die casting, and chemical synthesis.

Reliable supply chain: We maintain a robust logistics network ensuring timely delivery to domestic and international partners.

Technical support: Our expert team provides detailed guidance on product selection, storage, and usage for different applications.

Sustainability commitment: We actively implement environmentally responsible production methods and promote recycling initiatives within the zinc industry.

As one of the trusted suppliers in the region, Stavian Industrial Metal continuously invests in research, technology, and quality improvement to enhance the performance and environmental compatibility of refined zinc products.

The future of refined zinc lies in technological advancement and sustainable innovation. With global infrastructure growth and the shift toward renewable energy systems, demand for high-purity zinc will continue to expand. The metal’s ability to protect steel, support battery innovation, and serve as an eco-friendly material ensures its long-term relevance across diverse sectors.

At Stavian Industrial Metal, we anticipate a new era of growth for the refined zinc industry—driven by digital transformation, circular economy principles, and strategic cooperation among producers and consumers. By embracing cleaner technologies and maintaining strict quality control, we aim to reinforce our role as a leading supplier of refined zinc in both domestic and global markets.

Through our expertise and commitment to excellence, we continue to deliver refined zinc solutions that empower industries to achieve superior performance, sustainability, and competitiveness in a rapidly changing world.

Readers see more

What is 20×20 Aluminum Profile? Characteristics and Quotation

Buy Zinc Ingot: Price Trends, Sourcing & Industrial Uses

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com