LED aluminum profiles have become a familiar lighting fixture in our lives, serving to enhance the aesthetic appeal and unique beauty of living spaces. Despite being a relatively new product, it introduces a fresh and delightful sensation, augmenting the enthusiasm for our living environments.

LED aluminum profiles are a type of lighting fixture composed of an electrical circuit mounted on aluminum bars alongside LED chips. Therefore, when desiring higher power consumption, the design needs to be improved to increase the number of LED chips.

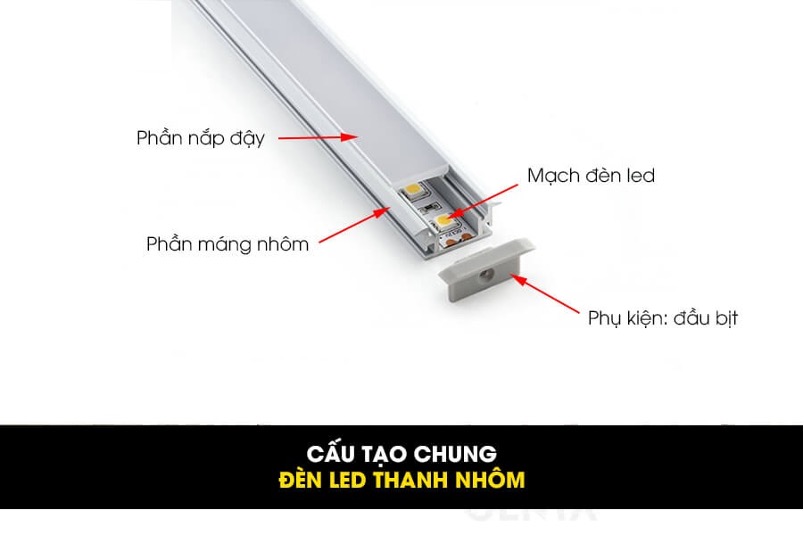

Being a rather unique product, shaped aluminum LED lights are constructed with specific components, including the following: the cover, aluminum housing, LED circuit, and end cap (image: top to bottom, left to right).

The plastic sheet is made from PMMA (PC PMMA – Poly Methyl Methacrylate) material. PMMA possesses characteristics such as flexibility, lightness, and resistance to breaking, making it suitable to replace glass or acrylic. PMMA has high mechanical strength, UV resistance, durability even when exposed to outdoor conditions, and excellent light transmission (92%). Therefore, PMMA plastic is highly suitable for insulation purposes.

Currently, for the application of LED aluminum profile, PMMA plastic sheets are divided into two types: transparent and frosted.

Transparent PMMA plastic sheets have the ability to transmit light entirely, while frosted sheets diffuse light to a certain extent. Depending on the specific application, users can choose the type of sheet that best suits their needs.

A layer of nylon is typically applied to the surface of PMMA sheets to facilitate easy removal after installation. This nylon cover serves as protection during transportation and installation, preventing scratches and preserving aesthetics

The aluminum LED profiles undergo anodization in a chemical bath containing concentrated sulfuric acid (H2SO4). During this process, the aluminum profiles corrode, gradually forming a thin layer of aluminum oxide on the surface. This aluminum oxide layer is extremely durable and hard, with hardness comparable to that of diamonds. Consequently, these anodized aluminum profiles exhibit excellent corrosion resistance, rust resistance, and durability in various environmental conditions.

Due to its high hardness, anodized aluminum is increasingly used in prominent construction projects, including structural frames, door frames, glass partitions, and more.

Currently, there are over 400 different models of shaped aluminum LED profiles available on the market, catering to a wide range of lighting needs for various applications.

LED strips designed for shaped aluminum LED lights have evolved significantly compared to traditional LED strips. They are now compact, with surface-mounted LEDs and exposed solder pads, making it easier to cut and connect sections.

The underside of the LED strip is equipped with adhesive backing. Users can peel off the protective layer and directly attach the LED strip to the aluminum profile. This design allows the aluminum profile to dissipate heat more effectively, extending the lifespan of the LED strip. Additionally, the adhesive backing ensures secure and aesthetically pleasing installation compared to conventional LED strips.

The LED driver’s function is to convert high-voltage alternating current (AC) from the mains into low-voltage direct current (DC) to power the LED strip. The LED driver also supplies power to the entire LED circuit, including sensors.

Currently, there are various types of LED drivers available on the market, differing in wattage, size, and output voltage. Therefore, when selecting an LED driver, it is essential to choose the appropriate model to provide the required load for the entire LED circuit.

Not all shaped aluminum LED lights come equipped with sensors. However, to enhance convenience, many LED profiles now incorporate sensors. There are various types of sensors, but the most common ones include:

Each end of the aluminum profile is fitted with end caps to prevent dust and dirt from entering and contaminating the interior. This protection ensures that the LED strip inside remains clean and well-preserved. One end cap typically has a small hole for threading wires through, while the other end is sealed.

These are significant design elements integral to aluminum LED profiles, and they serve to protect the internal LED strip from external environmental influences while also allowing precise positioning of light as desired.

Aluminum profiles, regardless of whether they are made of plastic, stainless steel, iron, or other materials, all use non-slip grooves to securely fasten accessories. These accessories are included with each product when we place an order.

Most large-sized aluminum profiles are specifically designed for creating pendant lights and are typically supplied with cable suspension accessories and ceiling mounting brackets.

Through the integration of LED technology with shaped aluminum LED profiles, the ability to excel in the market has significantly increased. This is clearly demonstrated through the outstanding features of this lighting device:

The primary purpose of using aluminum profiles for LED lights is to enhance protection and extend the lifespan of the lights.

LED light profiles are typically manufactured using heat-dissipating materials that offer excellent electrical insulation, thermal insulation, and high load-bearing capabilities.

They allow for flexible design changes to suit different installation locations or individual needs.

LED lights are classified into two standard categories based on protection levels: IP20-rated LED strip lights, providing excellent water and moisture resistance, and LED lights designed to fit within aluminum channels, protected by a transparent adhesive layer, with an IP68 rating, suitable for underwater installation.

Aluminum LED profiles are commonly available in two voltage options: 12V and 220V. For 12V LED lights, they are typically suitable for cabinet shelves, narrow spaces, or edge lighting. On the other hand, 220V LED lights emit a brighter, more defined light with excellent quality. Consequently, they are often used for outdoor illumination and in areas requiring high brightness or wide coverage.

Manufactured using modern and advanced Anodized technology.

Made from aluminum material, manufacturers can create various designs in terms of size and shape, including U, V, and other configurations.

When combined with LED technology, these lights inherit the outstanding advantages of modern LED lights. They incorporate technology to eliminate ultraviolet rays and radiation, ensuring maximum user safety, making them suitable for interior decoration.

Currently, shaped aluminum LED profiles can produce highly realistic lighting that is non-glaring and offers a wide range of colors from warm to cool (from 2700K to 6500K). These LED profiles can emit most basic colors and mix various shades of light. Hence, this product is suitable for various purposes, needs, and different decorative environments.

Thanks to modern LED technology, it ensures excellent longevity and quality for these lights.

Furthermore, this type of lighting comes in a wide range of colors and power options. Individuals can easily choose from various models that suit their preferences, such as Recessed Shaped Aluminum Profile 2309, Surface-Mounted Shaped Aluminum Profile 1709, Surface-Mounted Shaped Aluminum Profile 6535, and more.

Most importantly, these LED lights not only focus on light quality but also enhance aesthetics and entertainment.

With these outstanding advantages, manufacturers have focused on cost reduction and providing maximum benefits to consumers.

The demand for LED aluminum profiles is increasing daily due to:

Made from aluminum alloy and treated with anodized surface processes, aluminum profiles become remarkably rigid and durable. Polycarbonate (PC) and Poly Methyl Methacrylate (PMMA) materials are renowned for their exceptional durability. LED aluminum profiles benefit from the robustness of these materials.

Aluminum profiles serve the purpose of safeguarding LED strips from external factors like temperature, humidity, dust, water, and other environmental influences.

Users can easily customize the shape and press the aluminum profile to make it waterproof, dustproof, and fire-resistant.

These are the outstanding features of common LED light strips on the market. The Color Rendering Index (CRI) is typically above 80, with power ratings ranging from 10W to 18W/m, providing excellent lighting from moderate to strong.

Various diffusion adhesives are available in different finish layers, such as diffuse, matte, recessed, and more. Users can create different designs by cutting and connecting LED strips according to their needs.

LED aluminum profiles can be combined with various sensors, such as infrared sensors, touch sensors, wave sensors, open/close sensors. Therefore, users can easily have a living space with a full spectrum of colors without worrying about turning lights on or off for energy savings whenever they leave the house.

LED aluminum profiles become more popular when combined with various sensors such as motion sensors, infrared sensors, and more. This is the secret to transforming LED lights into an artistic masterpiece.

As a result, with the increasing demand for technology-driven lifestyles, this product is gradually becoming an essential item in everyone’s living spaces.

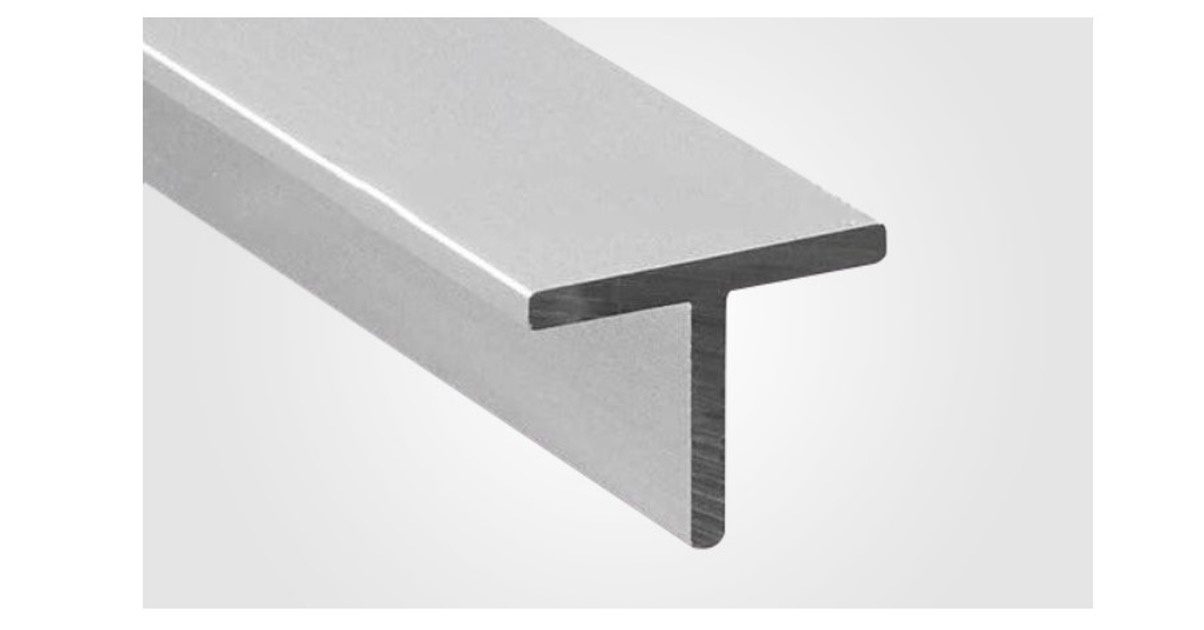

In reality, there are numerous types and shapes of shaped aluminum profiles available in the market. However, when considering the overall, most experts will categorize them into four main types: V-shape, U-shape, O-shape, and T-shape.

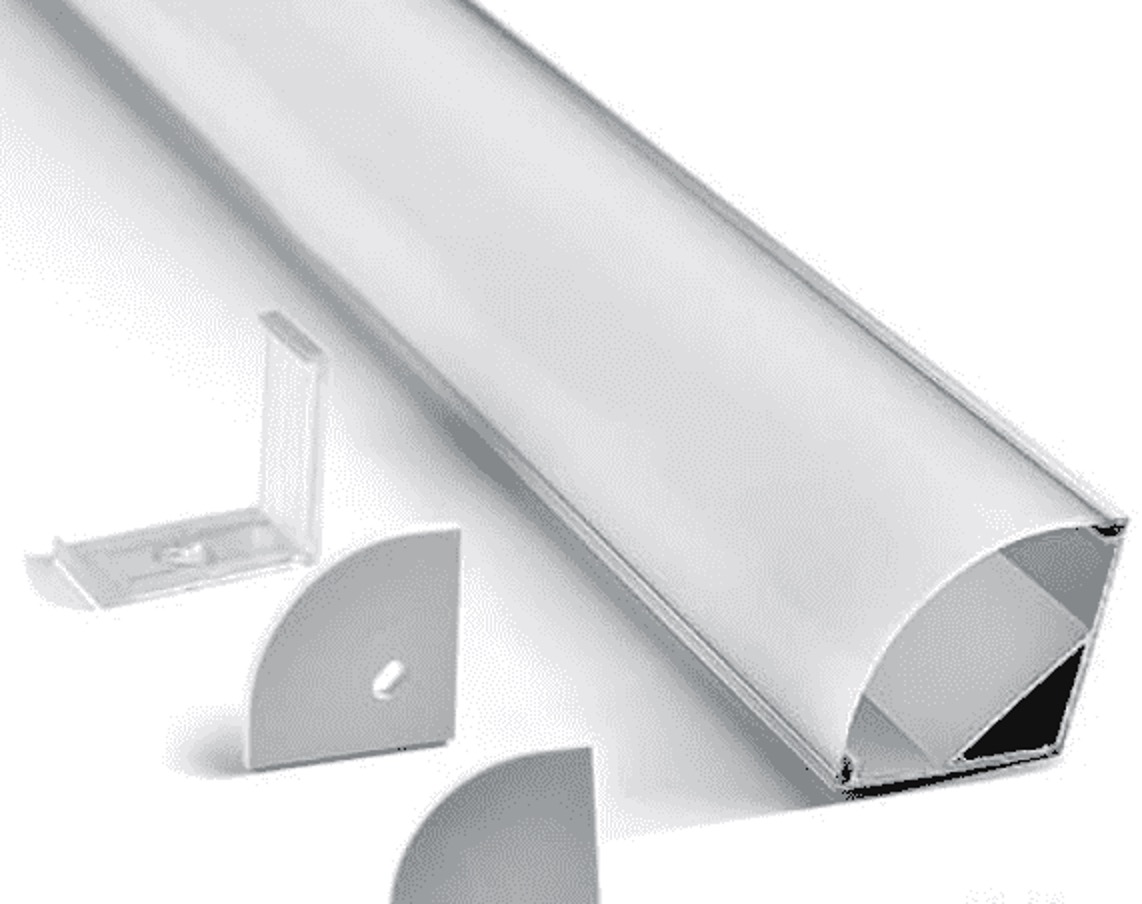

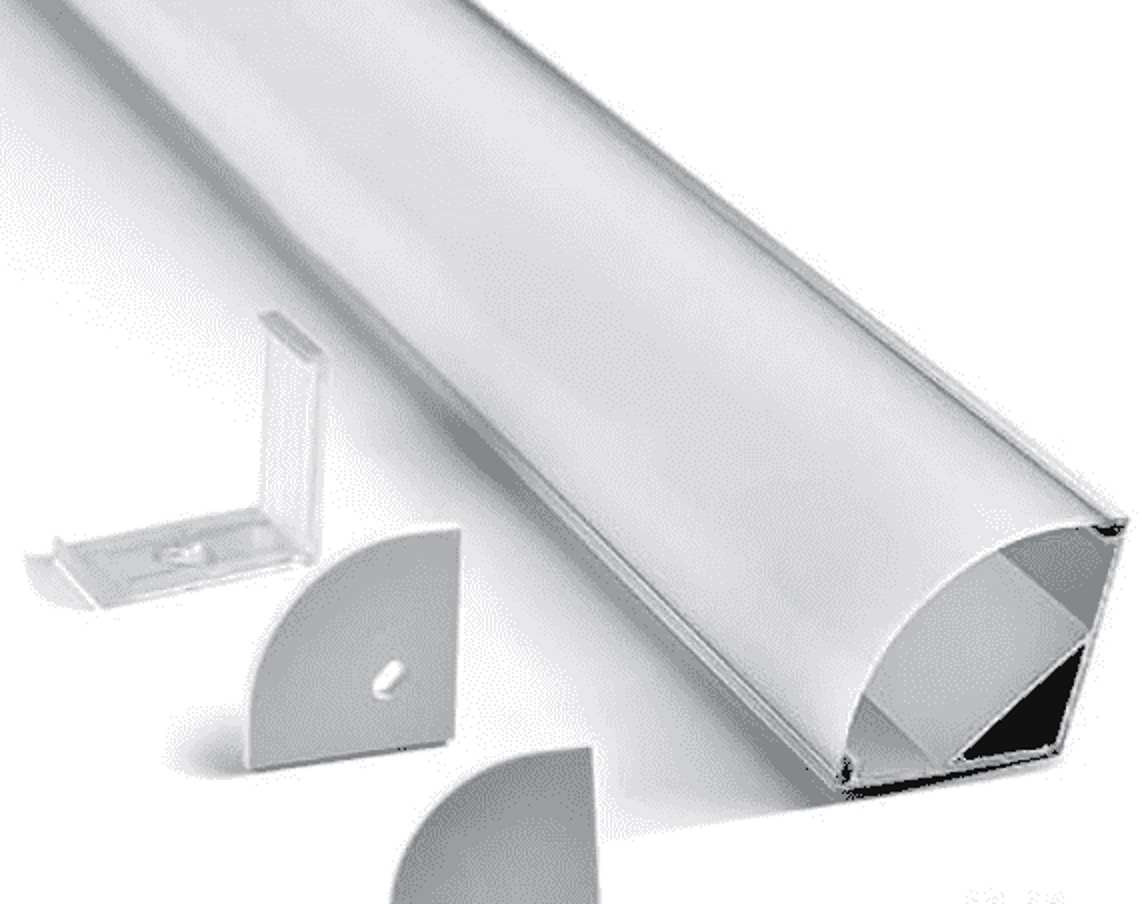

If you go to shopping centers or brightly lit houses, you’ll often see V-shaped aluminum profiles emitting light from every corner. These profiles can emit light at up to a 90-degree angle, brightening up every nook and cranny.

V-shaped aluminum profiles have a design with two contact surfaces that can fit into corners. Therefore, this type of light is usually surface-mounted without the need for recessed installation, yet it still enhances the aesthetics of your design.

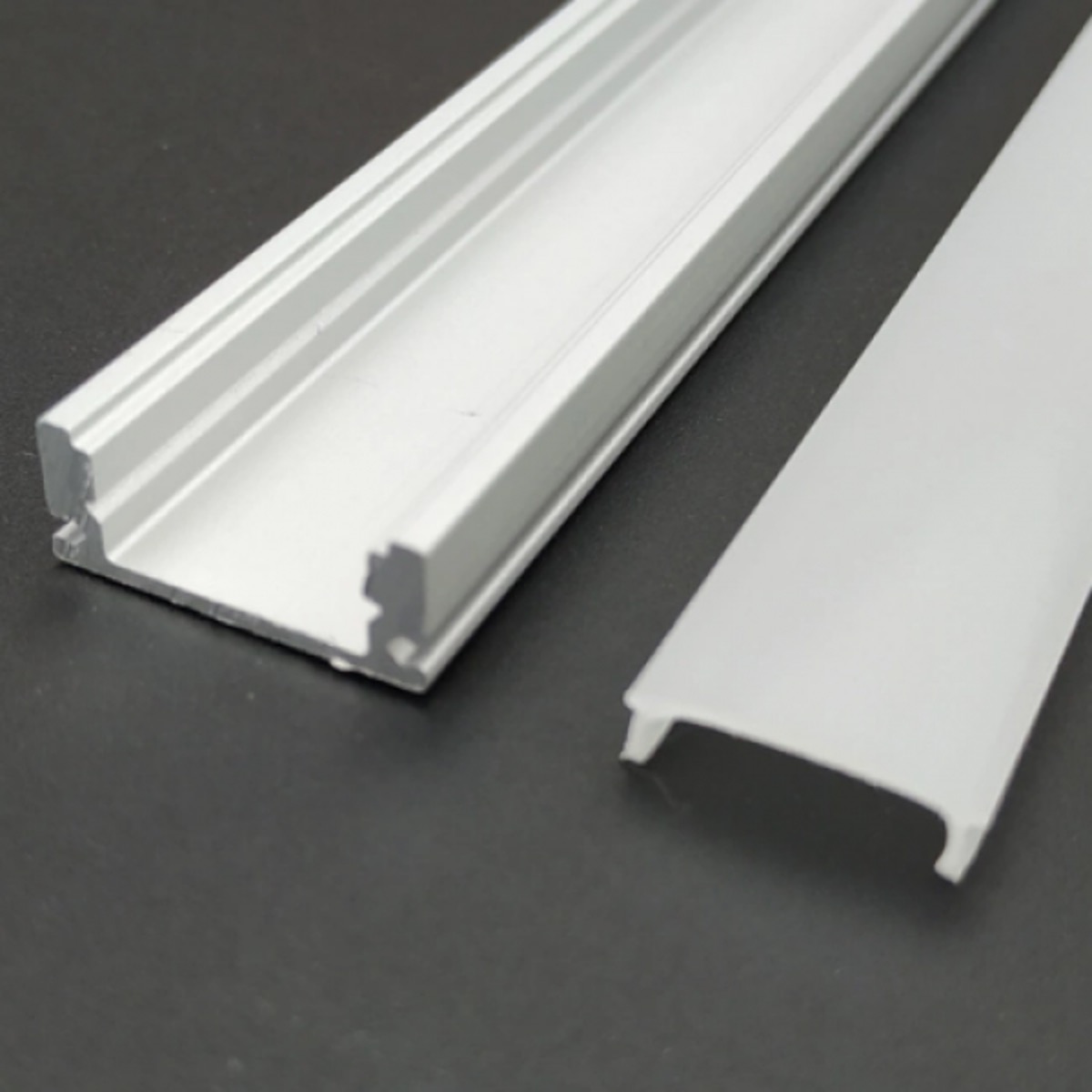

For U-shaped aluminum profiles, most designers prefer to use them in various applications such as surface mounting in wardrobe lighting, artwork illumination, handrails for staircases, mirrors, under staircases, etc. In some cases, U-shaped profiles may also be used for recessed installation into walls or fixtures. During the installation process, technicians typically assess the feasibility and overall aesthetics of the area that needs decoration.

U-shaped aluminum profiles for LED lights are often used for surface mounting, making them sleek and elegantly curved, which enhances their aesthetic appeal.

However, users should still choose a reputable installation service with high craftsmanship to ensure maximum decorative efficiency, safety, and aesthetic enhancement for their living spaces.

These are among the most versatile profiles available. T-shaped LED aluminum profiles are often preferred for recessed installation into walls, ceilings, or in decorative fixtures.

A distinctive feature of recessed installation is the need to drill into the surface to create a groove that fits the aluminum profile perfectly. During the installation process, it’s almost inevitable that the grooves won’t be perfectly flat. The T-shaped section of the aluminum profile extends to cover these imperfections, ensuring the best aesthetic outcome for the project.

The applications for T-shaped aluminum profiles for LED lights are diverse, including installation on ceilings, walls, or even underground. For homes or spaces that frequently require artistic lighting installations, you’ll likely find this type of T-shaped aluminum profile.

With the increasing demand for these profiles, manufacturers have produced various sizes and designs. Therefore, when purchasing, it’s advisable to consult with architects or knowledgeable technicians before proceeding with the installation.

With the trend of simple architectural designs that emphasize depth in modern homes, the use of O-shaped aluminum profiles is becoming increasingly popular. This type of aluminum profile is typically used for suspended applications and is not attached to any surface.

You can often find the application of O-shaped aluminum profiles suspended from the ceiling or used as desk lamps.

When installing LED lights into this tubular profile, it usually requires experienced technicians to ensure that the installation does not interfere with the internal circuits, which could potentially lead to short circuits or damage.

With the outstanding features mentioned earlier, LED aluminum profiles are now an excellent choice for consumers when it comes to installation and interior decoration. They can make your living space look noticeably more elegant and modern. Let’s explore the specific applications of this type of lighting in more detail:

The typical characteristics of this type of lighting are as follows:

They have a high brightness output, ensuring durability, making them suitable for outdoor installations.

You can use them to illuminate spaces such as balconies, gardens, or install them flush with the ground to light up pathways every evening.

With their modern design and vibrant, clear lighting, they create a dazzling atmosphere every night, adding vitality to your outdoor spaces.

LED aluminum profiles for glass cabinets, kitchen Cabinets, living room cabinets, etc.

These are low-power, normal heat-dissipation candlelight LEDs, making them more suitable for small spaces that don’t require high-intensity lighting. They work well when installed on cabinet shelves, decorative tables, and other areas. Thanks to the aluminum profile design, they protect the lights from external factors, ensuring durability and longevity. This means you can install them in kitchen cabinets worry-free, as they are resistant to moisture and fire hazards, ensuring their longevity.

Made from aluminum, this type of light comes in various designs and styles, which greatly enhances flexibility in installation. This is one of the reasons why LED aluminum profile lights are commonly used for wall mounting.

Similar to the aluminum profile lights used for wall mounting, this type of light is also applied for ceiling installation, with similar characteristics and functions.

LED aluminum profile lights are quite popular nowadays, so the installation process is relatively straightforward. Therefore, there are various installation methods for aluminum profiles for you to choose from. Many people prefer to install the LED aluminum profile in its entirety before attaching it to the desired location, while others may directly mount the aluminum profile and then proceed to attach the LED strip and diffuser.

Here are detailed steps for installing LED aluminum profiles for your reference:

LED aluminum profile pricing

There is a wide variety of LED aluminum profile models available today, providing customers with more options for choosing styles. Consequently, product prices may vary depending on the selected design and material.

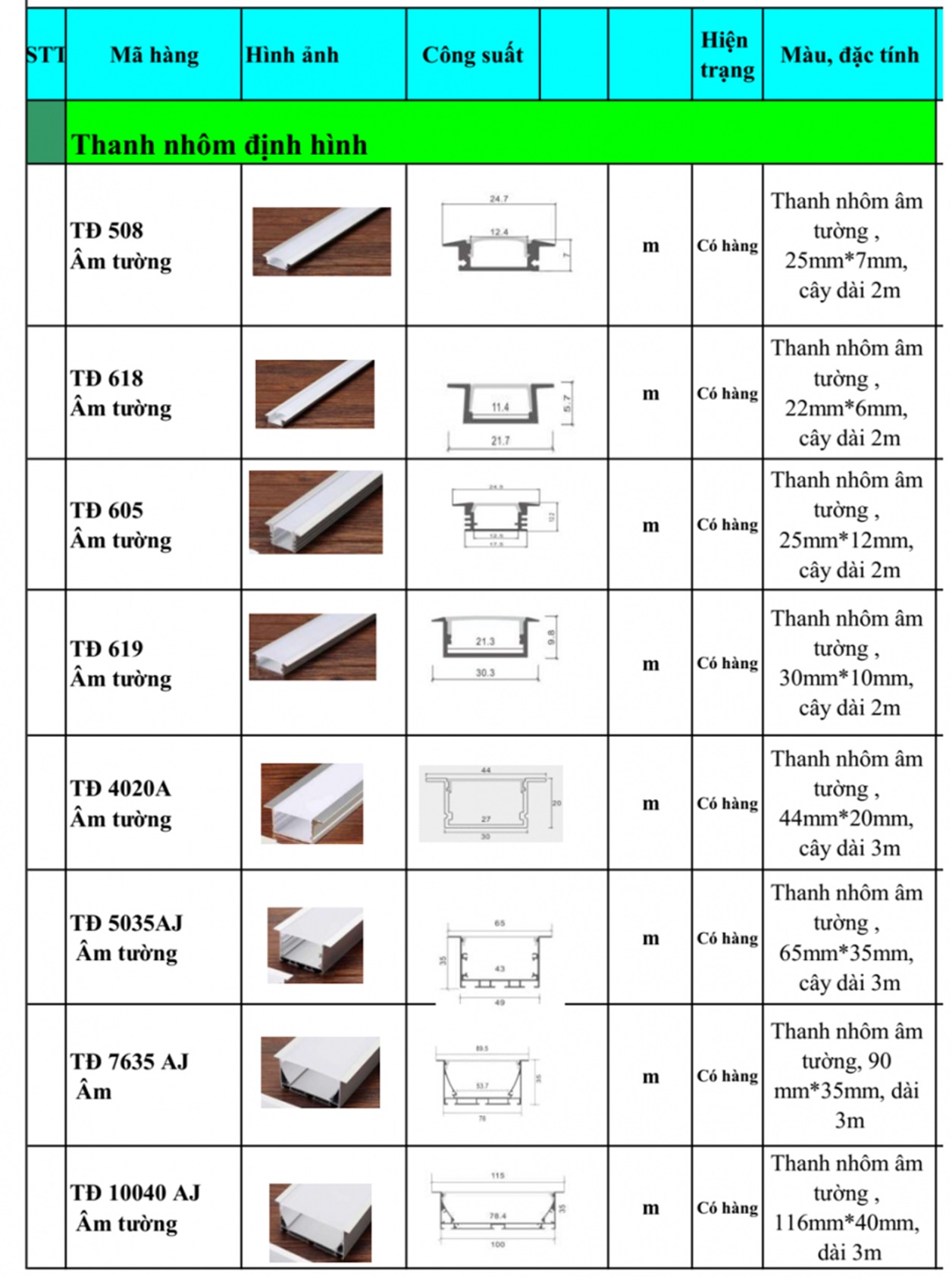

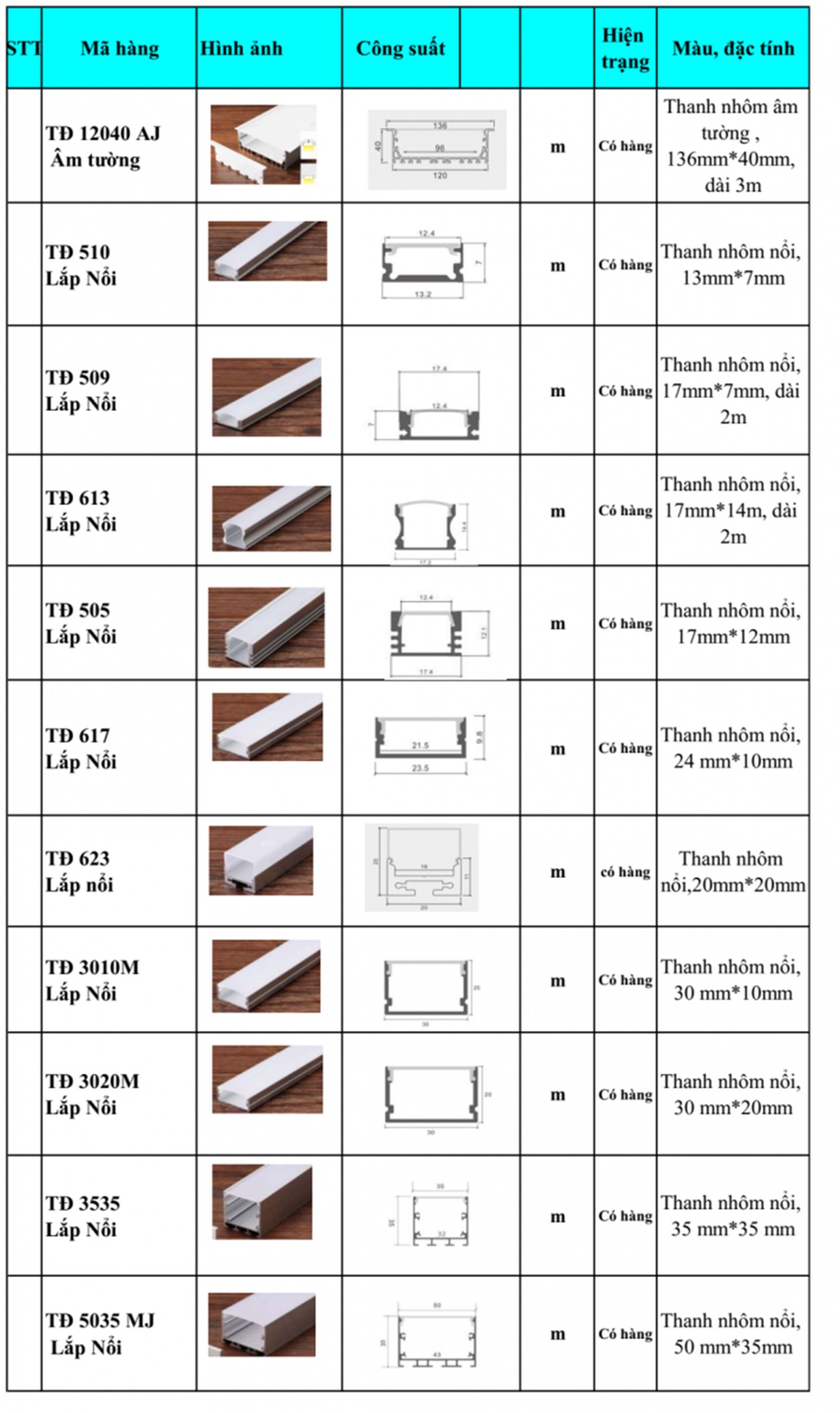

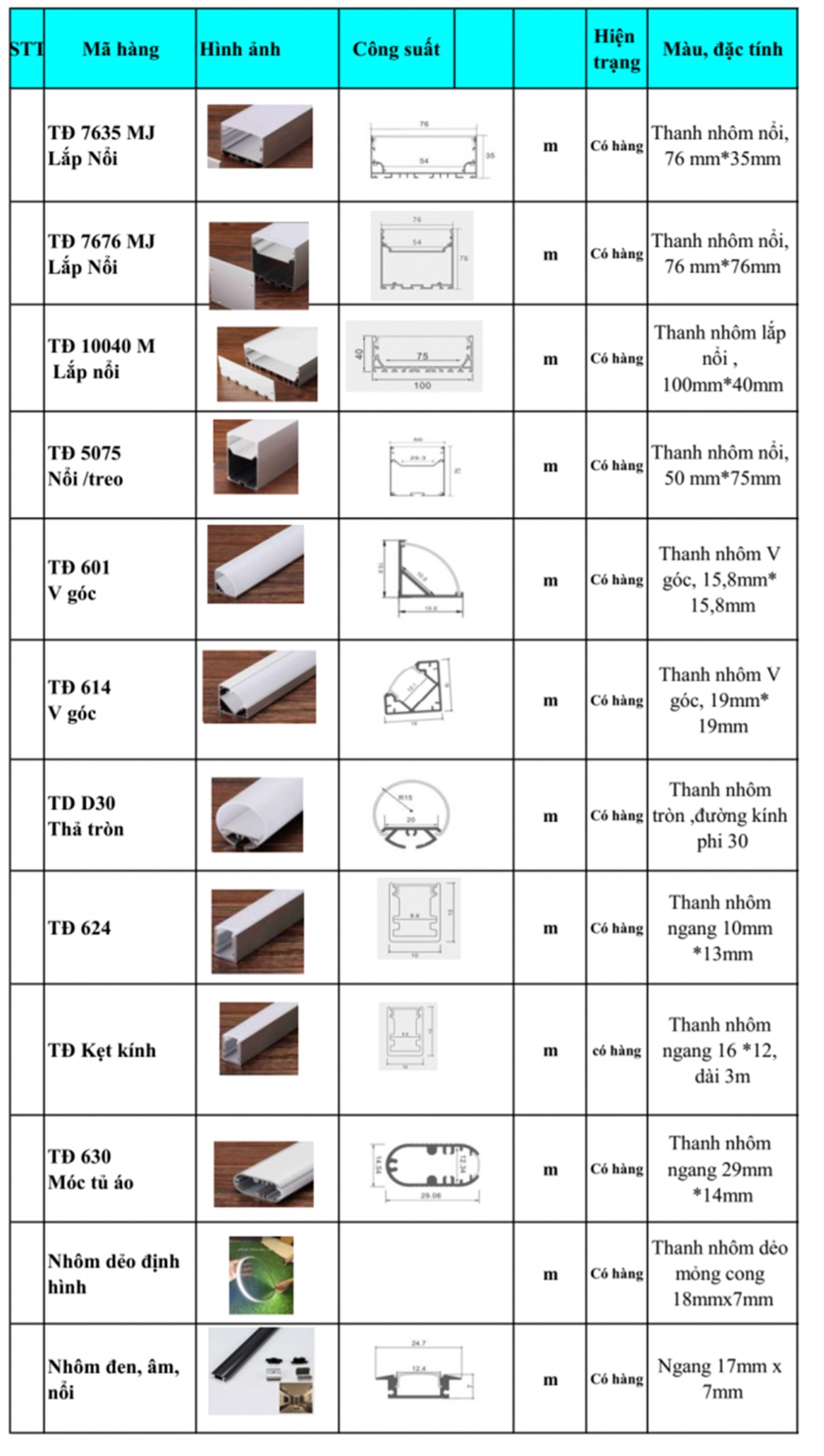

Here is an updated price list for LED aluminum profiles. All customers can refer to it to make the most suitable product choices for their projects.

| No | LED aluminum profile price list | Retail price (m) |

| 1 | LED Aluminum Profile V1616 Corner Mount – V1616 | 35.000đ |

| 3 | LED Aluminum Profile U508 Y-Shape Recessed Mount – U508 | 35.000đ |

| 4 | LED Aluminum Profile U509 Surface Mount – U509 |

35.000đ |

| 5 | Premium 12V 2835 LED Strip Light 168 LEDs 16W | 50.000đ |

| 6 | Premium 12V 2835 LED Strip Light 120 LEDs 5m Coil 10W | 35.000đ |

| 7 | Motion Sensor, Open/Close Sensor – CMVT12V | 135.000đ |

Please Note: The LED Aluminum Profile price list provided here is for reference only, and prices may vary at specific times. For accurate pricing, customers, construction contractors, or lighting equipment dealers are encouraged to contact Stavian directly for the most detailed consultation.

Where can you buy LED aluminum profiles? With the sole aim of providing the best-quality LED lighting products to customers, Stavian is undoubtedly the most reliable and top-notch choice for every household.

At Stavian Industrial Metal, we always ensure to supply all types of high-quality LED aluminum profiles, offering well-branded products with clear origins. All products are carefully selected and inspected to maximize customer satisfaction.

Throughout its operation, Stavian Industrial Metal is highly confident in delivering the best LED products for various projects. Accompanying this is a reasonable pricing policy, bringing many advantages and ensuring the lowest costs for customers.

The Stavian Industrial Metal brand not only provides goods directly at showrooms but also offers LED products through an online platform. Customers nationwide can easily access and make LED product purchases from Stavian by simply picking up the phone and calling the hotline number.

Stavian Industrial Metal always provides customers with genuine warranty certificates, along with a return policy in case of any manufacturer-related issues. Therefore, customers can have complete confidence and trust when choosing to purchase our products.

The above information provides a clearer understanding of LED aluminum profiles. If you have a need for high-quality products at competitive prices, please feel free to contact us for detailed advice. For all contact information, please visit:

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com