In the field of architectural construction, bolts, nuts, welding joints,… are often used to establish beam connections. However, what we want to discuss today is the gusset plate. So, if you want to understand more about what a gusset plate is, then refer to the information we’ll cover in the following article.

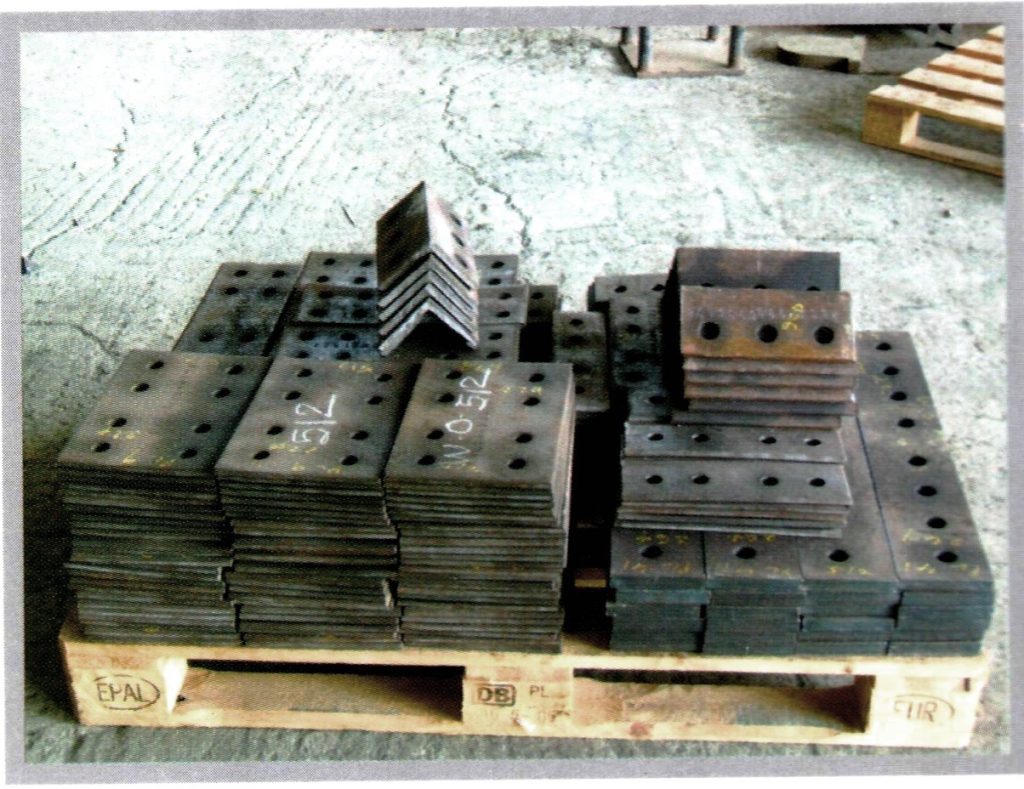

Gusset Plate is a general reference for a steel plate designed in a square shape and positioned at the end of a concrete pile. The primary purpose of a gusset plate is to weld and connect the two ends of concrete piles together. This effectively secures the two ends of the pile, enhancing stability when driving the pile into the ground. Additionally, gusset plates are also utilized for reinforcement within structural designs, serving as fixed edges for nails, bolts, screws, and other fasteners.

A steel gusset plate is a type of construction material that is designed to be simple and flexible, making it suitable for various shapes and applications in construction. Gusset plates are used to connect beams and columns by threading bolts or screws through pre-drilled holes on their surfaces.

Here are some common types of steel gusset plates:

Steel gusset plates are made from various types of materials, depending on technical requirements and the intended use for each project. Here are details about the common types of materials used to make steel gusset plates:

To protect gusset plates from external factors, it’s recommended to apply a layer of paint after completing the construction. Painting not only enhances the aesthetic appearance of the structure but also extends the lifespan of both the gusset plate and the entire building structure.

One of the crucial factors in choosing gusset plates is the material. Typically, gusset plates are made from iron or steel due to their high strength and adaptability to various structures.

However, gusset plates can also be made from aluminum or copper (less common). When using these materials for gusset plates, they are suitable for smaller and simpler structures because of their ability to bear loads and easily change shape.

In reality, steel gusset plates can be made from a wide range of different materials, diverse in terms of size and weight, suitable for various intended uses based on demand. Therefore, nowadays, steel gusset plates continue to be widely applied in constructing modern structures with the following outstanding advantages:

Steel gusset plates are always a crucial construction material that plays an important role in most architectural projects and is widely utilized in various fields and industries.

Notable applications of this product include:

Details of Common Gusset Plate Sizes Nowadays include:

Moreover, the dimensions of steel gusset plates can also be customized according to customers’ specific requirements to best suit the intended use in various construction projects.

The current price of steel gusset plates will range from around 10,000 VND/kg to 15,000 VND/kg.

The price of gusset plates with dimensions of 10×10 round holes will be approximately from 15,000 VND/kg to 17,000 VND/kg.

For gusset plates with dimensions of 20×20 round holes, the price will fall within the range of 50,000 VND/kg to 67,000 VND/kg.

The column base gusset plates will cost around 30,000 VND/kg to 45,000 VND/kg.

The price levels provided here are for reference only. The cost of this product will vary based on specific time periods. To obtain the most accurate price corresponding to the quantity of gusset plates required, you can contact the Hotline at (+84)975271499.

For the latest updated steel gusset plate price list, please refer to the provided link.

| No | Dimensions | Pricing (VND) |

| 1 | gusset plate 100x100x10 | 13100 |

| 2 | gusset plate 200x200x10 | 13100 |

| 3 | gusset plate 250x250x10 | 13100 |

| 4 | gusset plate 300x300x10 | 13100 |

| 5 | gusset plate 350x350x10 | 13100 |

A steel gusset plate serves as a connection to link discrete structures together. This ensures maximum stability when these components are assembled into a cohesive unit, with several notable considerations as follows:

The width of the plate must accommodate the arrangement of connections with the length of the weld and the distribution of bolts on its surface.

The thickness of the steel gusset plate is determined based on two primary factors: material fragility and load-bearing capacity. If the plate is too thick, it can impact the bolts, while being too thin might affect the connection due to insufficient elasticity that the gusset plate demands.

Beam-column design: The steel gusset plate must fulfill dimensional and thickness requirements with respect to the position of beam and column. It should provide adequate surface area for welding connections between beams and bolts. The angle between the edge of the plate and the beam axis should not exceed 15 degrees to prevent insufficient force transmission.

Force and structural loads: The steel gusset plate must withstand horizontal and vertical forces when connecting beams and columns. Simultaneously, it should ensure optimal strength and rigidity to prevent deformation under substantial force.

Construction environment and location: The selected material for the gusset plate should exhibit good resistance to forces and environmental factors such as temperature, humidity, rain, wind, light, etc. It should minimize susceptibility to corrosion when exposed to water, salt, or chemicals in construction settings.

Therefore, choosing the appropriate gusset plate in accordance with the requirements of each project is crucial to ensure maximum efficiency and safety for structural designs.

Currently, the market offers a wide variety of steel gusset plate types, such as square gusset plates, triangular gusset plates, rectangular gusset plates, and more. However, the choice of gusset plate shape, whether circular, oval, or any other dimensions, depends on specific purposes and requirements for various construction projects. Users have the flexibility to select the most suitable shape and size for their projects. Here are some specific examples:

As previously mentioned, the dimensions of steel gusset plates in the current market are highly diverse to accommodate the specific needs of each construction project. Therefore, the common unit of measurement used for gusset plates is millimeters (mm).

Here are some examples of gusset plate sizes and their applications:

1. 100 x 100 x 10: This type of gusset plate has dimensions of 100mm in length and width, with a height of 10mm. It is the smallest-sized product and is mainly used for road paving, floor lining, and sidewalk construction.

2. 200 x 200 x 10: This gusset plate measures 200mm in length and width, with a height of 10mm. It falls within the medium-sized range and is primarily used for purposes like courtyard lining, roof lining, and balcony railings.

3. 250 x 250 x 10: With dimensions of 250mm in length and width and a height of 10mm, this gusset plate is slightly larger than the 200 x 200 x 10 type. It is commonly used for rooftop lining, wall lining, and window construction.

4. 300 x 300 x 10: Measuring 300mm in length and width, and 10mm in height, this gusset plate is relatively large. It is often used for house foundation lining, staircase lining, and gate construction.

5. 350 x 350 x 10: This gusset plate has dimensions of 350mm in length and width, and a height of 10mm. It is the largest-sized option available and is primarily used for applications such as garden paving, pool lining, and fence construction.

These sizes and their applications demonstrate the versatility of gusset plates to meet various construction needs.

Perforated steel gusset plates are widely used in various industries such as construction, mechanical engineering, interior design, and decoration. They offer numerous prominent advantages, including:

These plates find widespread applications in practical scenarios such as creating staircase railings, designing clothes drying racks, partitioning living spaces, constructing machinery frames, providing flooring for industrial workshops, and serving as sun and rain protection.

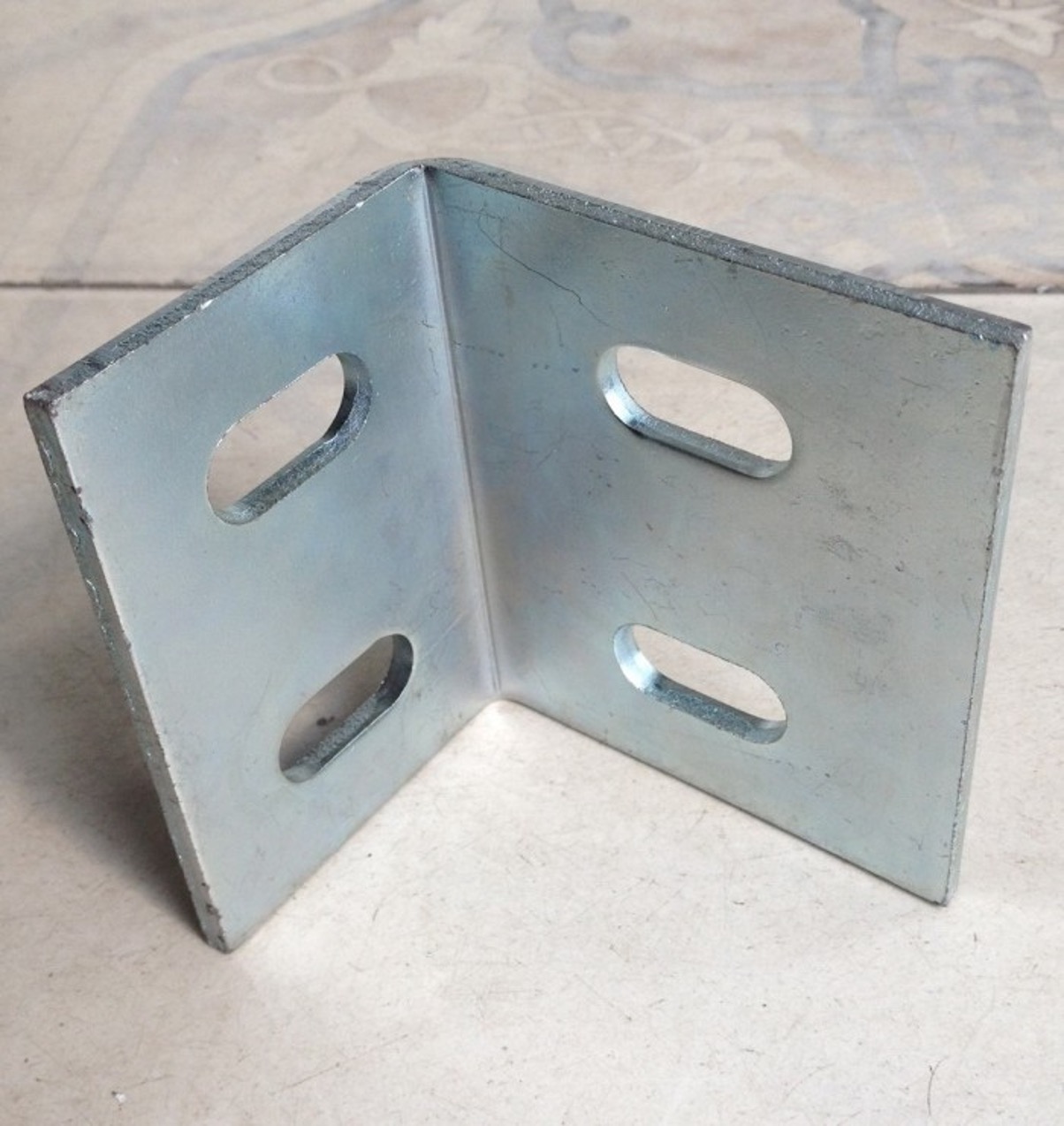

Folding steel gusset plates are extensively used in various designs and manufacturing processes, catering to different shapes and forms. They effectively meet the technical requirements and aesthetic aspects of each project. These products are typically constructed in a U or L shape, with welded connections between the bars attached to the gusset plate on both sides. The angle between the edge of the folding steel gusset plate and the beam’s axis should be greater than or equal to 15 degrees to maximize load-bearing capacity and prevent deformation.

The primary function and role of folding steel gusset plates lie in establishing connections between beams and columns in projects such as warehouses, high-rise buildings, and bridges. They are often coated with paint or other protective coatings to enhance durability and prevent corrosion.

Galvanized steel gusset plates are products made from steel and coated with a layer of galvanized zinc on the surface to enhance their exceptional corrosion resistance. These finished products are often used in construction projects requiring high aesthetic appeal or in humid, high-temperature environments. They offer durability, a glossy appearance, easy cleaning, and maintenance. However, galvanized steel gusset plates often come with a relatively higher cost, lower load-bearing capacity, and are prone to scratches upon impact.

SS400 steel gusset plates find widespread applications in the construction industry today. This type of steel possesses strong hardness and tensile strength, making it highly suitable for industrial projects, prefabricated steel structures, and road bridges. SS400 steel has excellent corrosion resistance, ensuring increased longevity and durability when used in various constructions. However, the major drawback of this steel type is its significantly higher cost compared to other steel types, along with difficulties in processing and welding.

SUS 304 and SUS 201 are types of gusset plates made from stainless steel, which is known for its corrosion resistance properties. These stainless steel gusset plates possess excellent anti-corrosion capabilities, high durability and provide long-lasting longevity.

Steel column base gusset plates are commonly used gusset plate types in the present day. They are often made from cold-rolled steel, galvanized steel, or various stainless steel types. This product is specifically designed to connect beam-column systems, link steel structures, or be used in foundation construction.

These are gusset plates crafted in a square box shape and welded at the top of concrete piles. They are used to connect two concrete piles during pile driving. This type of gusset plate enhances the load-bearing capacity during pile driving, especially at joint positions, bending points, or discrete connection points in various joints.

Các loại bàn hóa trên đây chỉ là một trong những mẫu mã điển hình được ứng dụng rộng rãi trên thị trường. Phụ thuộc vào mục đích hay cách sử dụng vào các thiết kế công trình khác nhau mà quý khách hàng có thể đặt đúng với kích thước, hình dạng và độ dày phù hợp với từng nhu cầu.

In order to help you understand how to calculate the weight of steel gusset plates, it’s essential to grasp the mathematical formulas for application in computations.

By utilizing the following mathematical formula, users can quickly determine the weight of any steel gusset plate product with simple dimensions. The procedure is as follows:

Formula:

Weight of steel gusset plate (kg) = Thickness of the steel gusset plate (mm) x Width (mm) x Length (mm) x 7.85 (g/cm3) / 1000

Here, 7.85 (g/cm3) represents the density of steel.

For gusset plate products with more intricate shapes or dimensions, the calculation can be applied using the following formula:

Formula:

Weight of steel gusset plate (kg) = Thickness of the steel gusset plate (mm) x Area of the steel gusset plate (mm2) x 7.85 (g/cm3) / 1000

Again, 7.85 (g/cm3) signifies the density of steel.

Indeed, steel gusset plates possess the characteristics of being rigid, sturdy, and resistant to manipulation. Consequently, cutting these steel plates can be quite challenging. Therefore, we will discuss the four most common methods of cutting steel gusset plates as follows:

The primary advantage of this method is its rapid cutting speed, which saves a significant amount of time and effort. However, the resulting cut lines may not be aesthetically pleasing or precise; the cut edges tend to be distorted. Moreover, as the thickness of the plate increases, the quality of the cut diminishes.

This method of cutting steel gusset plates utilizes a laser beam. The laser beam is directed straight onto the surface where heat is needed to be transferred. This creates a transition that results in melting and vaporization at the contact points, forming empty spaces on the surface. The greatest advantage of this method is its high precision and aesthetic quality, eliminating the need for post-processing upon completion.

This cutting method can be considered one of the techniques passed down from a long time ago. It enables the quick cutting of thick steel plates. However, this method often leaves high bevels, resulting in a lack of aesthetics.

This method is also referred to as hydrodynamics. It involves using a high-pressure water jet to cut steel gusset plates. The main advantage of this method is producing a very small and smooth cut. Moreover, since water is used, the cutting process doesn’t generate heat, preventing deformation of the cut material.

Steel gusset plates are considered capable of connecting discrete structures to create a unified whole, enhancing load-bearing capacity. Steel gusset plates come in a variety of shapes and sizes, depending on their intended use, allowing users to order the most suitable option for their specific needs. A fundamental requirement for various types of steel gusset plates used in construction projects is that the angle between the edge and the longitudinal axis must exceed 15 degrees. This ensures that the gusset plate has the best load-transmitting capability.

Currently, steel gusset plates are widely applied in construction and mechanical projects to connect beam and column systems, establish bolted frame structures, and form house foundations.

Furthermore, steel gusset plates are also employed to reinforce various types of joints, enhance joint adhesion strength, address bending points, and facilitate discrete connections. This, in turn, increases structural stability when utilized in projects, ensuring optimal longevity for construction architecture.

In today’s market, there are numerous companies offering a wide range of steel gusset plates. However, one highly regarded company currently providing the best steel gusset plate products on the market is Stavian Industrial Metal Joint Stock Company. This brand is always the go-to source for supplying a large quantity of steel gusset plates with utmost credibility nationwide.

The prices of the various products supplied by Stavian are always offered with significant advantages, bringing high competitiveness to the market.

All products sold ensure genuine quality, the best in class, with relevant purchase contracts and documentation provided.

We also have a team of highly skilled and enthusiastic professionals with ample experience ready to assist and advise customers.

Moreover, Stavian Industrial Metal provides nationwide transportation support.

The above is a compilation of the most useful information about steel gusset plates. If you are researching and in need of purchasing this product, you can directly contact Stavian Industrial Metal Joint Stock Company for the most detailed advisory information.

For all contact information, please visit:

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com