In the construction industry, cold-rolled steel and galvanized steel are two commonly used materials for both residential and industrial projects. However, each type has its own characteristics and advantages, making them suitable for different needs. Understanding the differences between cold-rolled steel and galvanized steel helps users choose the most suitable product for their projects.

Below, we will provide a detailed comparison of these two types of steel to help you make an informed decision when building. Notably, Stavian Industrial Metal’s products always ensure high quality and meet the highest technical standards.

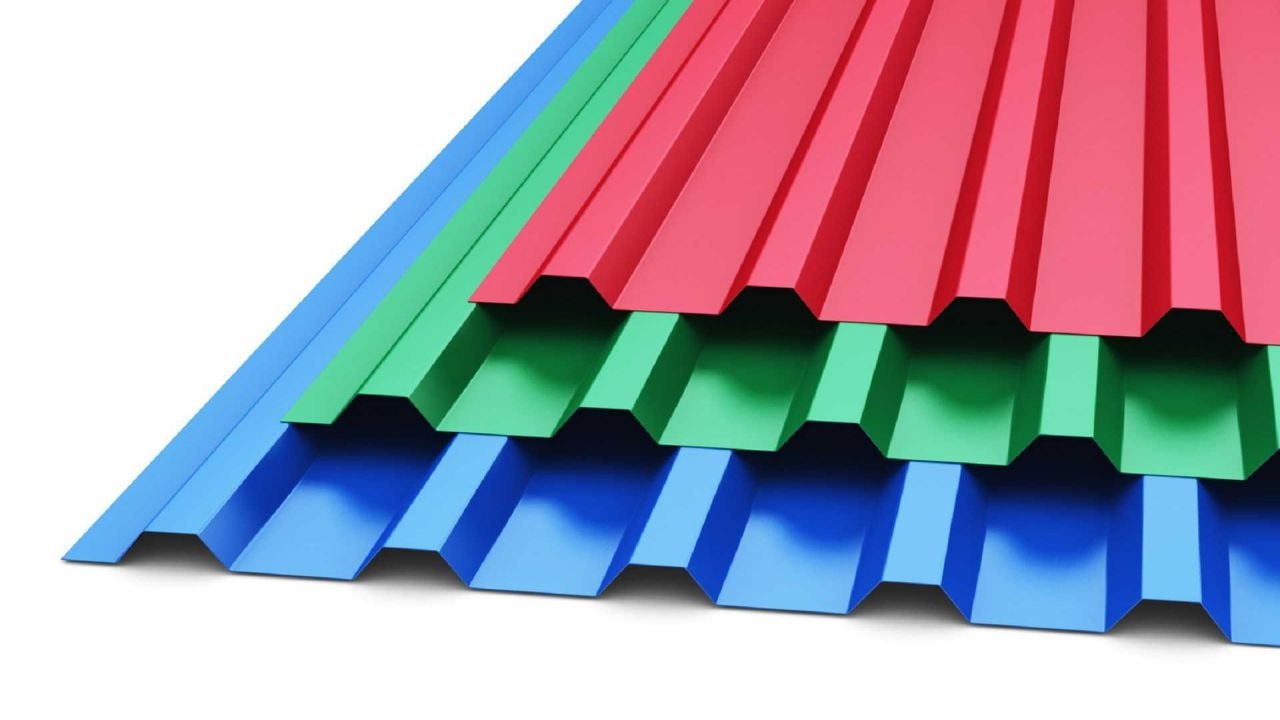

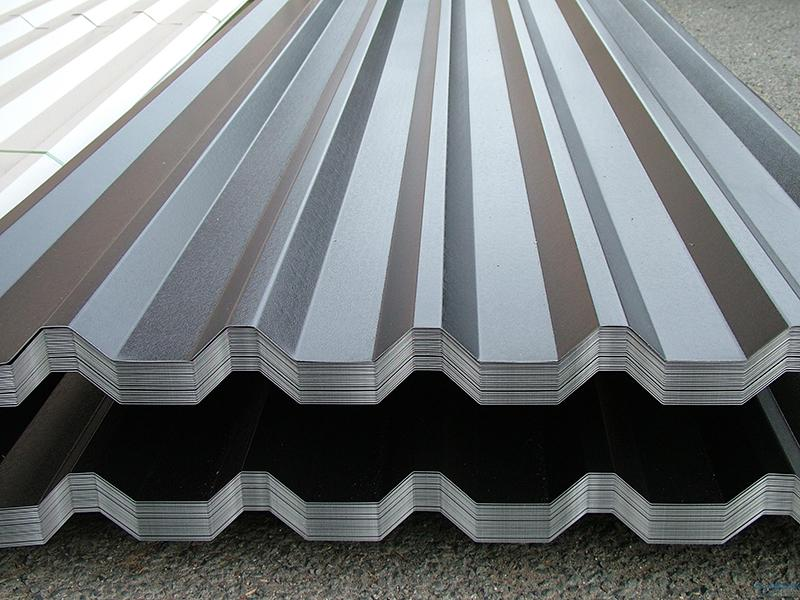

Cold-rolled steel is a type of steel coated with an aluminum-zinc alloy, consisting of 55% aluminum, 43.5% zinc, and 1.5% silicon. This coating gives cold-rolled steel superior heat reflection and corrosion resistance, making it highly advantageous in construction.

SEE MORE >>> What is Round Wave Steel?

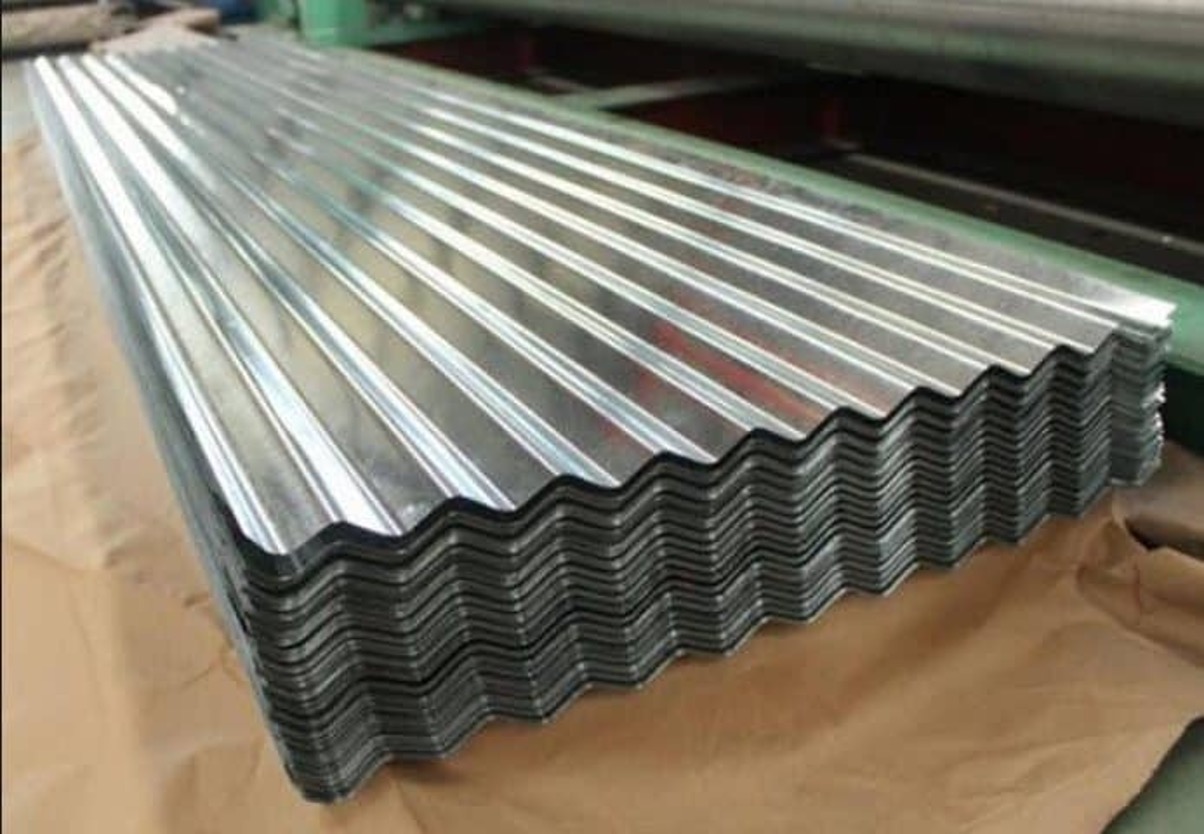

Galvanized steel is a thin sheet of steel coated with pure zinc to protect it from corrosion. This type of steel is widely used due to its affordability and is preferred for small-scale projects that do not require a long lifespan.

The table below provides a detailed comparison based on key criteria:

| Criteria | Cold-Rolled Steel | Galvanized Steel |

|---|---|---|

| Material | Aluminum-zinc alloy coated steel | Pure zinc-coated steel |

| Corrosion Resistance | Excellent, resistant to rust in humid and coastal environments | Moderate, prone to rust in humid conditions |

| Heat Reflection | High, keeps indoor spaces cooler | Low, absorbs more heat |

| Durability | Very high, lifespan of 20–30 years | Moderate, lifespan of about 10–15 years |

| Aesthetic Appeal | Shiny, modern appearance | Rougher, less glossy surface |

| Cost | Higher due to complex manufacturing | Lower, suitable for smaller projects |

| Applications | High-end homes, factories, projects requiring high durability | Temporary structures, warehouses, auxiliary buildings |

Cold-rolled steel is often chosen for projects requiring high durability and corrosion resistance, especially in high-humidity environments such as coastal areas or harsh climates. Common applications include:

SEE MORE >>> What is Color-Coated Steel?

Galvanized steel, with its low cost and flexibility, is commonly used for temporary structures or supporting constructions that do not require long lifespans. Common applications include:

Stavian Industrial Metal is a leading brand in supplying high-quality cold-rolled and galvanized steel in Vietnam. With advanced manufacturing technology and strict quality control processes, Stavian ensures that its steel products offer superior durability and are suitable for various projects.

SEE MORE >>> What is Square Wave Steel?

| Specification | Unit | Reference Price (VND) |

|---|---|---|

| Cold-Rolled Steel 0.3mm | m² | 18.000 – 25.000 |

| Cold-Rolled Steel 0.4mm | m² | 20.000 – 28.000 |

| Cold-Rolled Steel 0.5mm | m² | 22.000 – 30.000 |

| Specification | Unit | Reference Price (VND) |

|---|---|---|

| Galvanized Steel 0.3mm | m² | 15.000 – 20.000 |

| Galvanized Steel 0.4mm | m² | 17.000 – 22.000 |

| Galvanized Steel 0.5mm | m² | 19.000 – 25.000 |

For an accurate price quote on cold-rolled and galvanized steel products, contact Stavian Industrial Metal directly. Our team will provide detailed information on pricing, product quality, and exclusive promotions for customers.

Hotline: +84 24 7100 1868

Zalo: zalo.me/0975271499

Comparing cold-rolled and galvanized steel shows that each has its own advantages, making them suitable for different types of projects. If you need a high-quality, durable, and heat-resistant roofing solution, cold-rolled steel is the ideal choice. Meanwhile, galvanized steel is a cost-effective solution for temporary or budget-limited projects.

With Stavian Industrial Metal’s steel products, you can be assured of quality and pricing, ensuring the best fit for all your construction needs.

MORE REFERENCES

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com