Aluminum channels are essential components in structural framing, fabrication, and architectural projects thanks to their strength, corrosion resistance, and lightweight profile. They serve a wide range of applications, from building infrastructure to machinery enclosures, offering both durability and aesthetic value. One common question is: What makes aluminum channels a preferred choice over steel or plastic alternatives? Their high strength-to-weight ratio, ease of machining, and excellent performance in harsh environments make them an ideal solution for engineers, builders, and designers. At Stavian Industrial Metal, we provide high-quality aluminum channels tailored to various industrial standards and project needs, ensuring optimal performance and long-term reliability. Whether used in load-bearing structures or decorative trims, aluminum channels continue to set the benchmark for functional design and material efficiency.

Aluminum channels play a crucial role in modern engineering and construction projects due to their adaptability, strength, and corrosion resistance. At Stavian Industrial Metal, we supply a wide variety of aluminum channels designed to meet demanding structural and aesthetic requirements.

These profiles typically feature a U-shaped cross-section, making them highly suitable for load distribution, edge protection, framing, and support structures. Their combination of lightweight properties and mechanical strength allows for easy handling and long-term durability without compromising performance.

Aluminum channels are commonly used in:

Framing systems in construction and architecture

Vehicle and trailer fabrication

Electrical and HVAC equipment housings

Furniture and modular display systems

Their ability to resist oxidation makes them especially effective in environments with high moisture levels or exposure to chemicals, reducing maintenance needs and extending operational lifespan. This balance of performance and reliability makes aluminum channels indispensable across industries.

Overview of Aluminum Channels and Their Industrial Significance

Choosing the right type of aluminum channel depends on the intended application. At Stavian Industrial Metal, we offer multiple profiles and grades to match technical requirements, load capacities, and environmental conditions.

Standard U-channels are the most common and are used for general framing, protective edges, and support brackets. Their simplicity in shape makes them versatile and easy to cut, weld, or machine.

Typical uses include:

Reinforcing door and window frames

Border trims for wall panels

Brackets and base supports for shelving

They are often produced using alloys like 6061 or 6063, which offer a strong balance of formability and corrosion resistance.

Hat channels, which have a deeper and more defined profile than U-channels, are typically used in construction for furring walls and ceilings. Their raised center section provides added rigidity while maintaining a lightweight form.

Applications of hat channels:

Drywall ceiling installations

Ventilation and cable tray supports

Decorative facades and paneling structures

These profiles may come with anodized or powder-coated finishes, improving both the aesthetic and weather resistance properties.

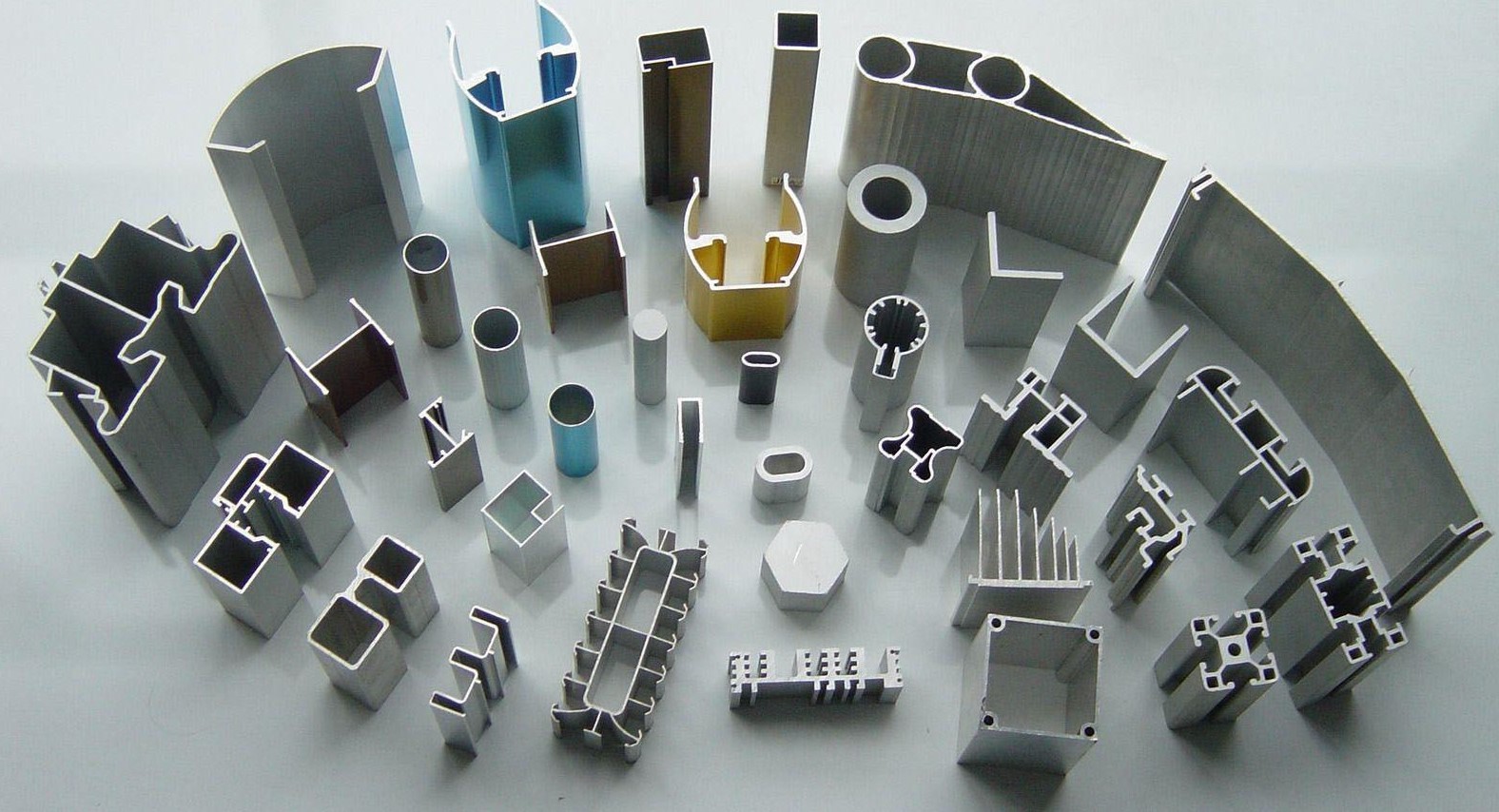

Some industries require aluminum channels manufactured to exact specifications, whether in terms of profile geometry, alloy composition, or finishing. At Stavian Industrial Metal, we provide custom extrusion services to accommodate unique project needs.

Custom options include:

Varying thickness and flange widths

Pre-drilled holes, slots, or notches

Specialized surface treatments (anodizing, brushing, or coloring)

Custom aluminum channels are widely used in aerospace, marine, and precision machinery sectors, where off-the-shelf profiles may not meet strict tolerance or performance criteria.

Selecting the correct material grade for aluminum channels is essential for ensuring optimal performance in specific environments. At Stavian Industrial Metal, we prioritize high-grade alloys that balance strength, machinability, and corrosion resistance.

The two most commonly used alloys include:

6061 Aluminum: Known for its high strength and good corrosion resistance. It’s heat-treatable and weldable, making it ideal for structural applications such as bridges, machinery frames, and transport components.

6063 Aluminum: Often used for architectural and aesthetic purposes due to its superior surface finish and formability. Common in window frames, signage, and decorative trim.

Key mechanical properties to consider:

Tensile strength: Varies by alloy and temper, typically 140–290 MPa

Yield strength: Approximately 110–240 MPa

Elongation: Indicates ductility, generally around 8–12%

Density: Around 2.7 g/cm³, contributing to low weight

Understanding these values helps engineers and designers choose the right profile that meets both structural and environmental demands, ensuring long-term reliability and safety.

Surface finishing enhances the functionality and appearance of aluminum channels while improving resistance to corrosion, wear, and UV damage. At Stavian Industrial Metal, we offer a comprehensive range of finishing services tailored to different applications.

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum, providing a hard, durable finish. This method not only increases corrosion resistance but also enables decorative coloring without fading.

Advantages of anodized channels:

Non-peeling finish that bonds to the metal

Long-lasting protection against weathering

Available in a variety of matte or gloss finishes

Powder coating involves applying a dry powder electrostatically to the surface, then curing it under heat to form a smooth, protective layer. This is particularly useful in environments with high mechanical wear or chemical exposure.

Key features:

Thicker coating than paint or anodizing

Resistance to chipping, abrasion, and impact

Wide selection of colors and textures

Our coating processes comply with environmental regulations and deliver consistent quality across production batches.

To ensure quality and compliance, all aluminum channels supplied by Stavian Industrial Metal adhere to recognized international standards. These standards govern material composition, mechanical properties, dimensional tolerances, and surface finishes.

We supply products that meet or exceed:

ASTM B221: Standard for extruded aluminum shapes

EN 755-9: European standard for tolerances and profiles

RoHS compliance: Safe for use in electronics and environmentally sensitive applications

ISO 9001: Quality management system certification

In addition, we provide mill test certificates (MTCs) and inspection reports for each order, offering full traceability and peace of mind for high-specification projects.

By aligning with these industry standards, we ensure that our aluminum channels are reliable, safe, and ready for demanding global markets.

Readers learn more

Aluminum Shapes: Types, Uses, and Benefits

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com