Looking for a versatile and long-lasting metal for your project? Learn about the advantages of mild steel flat bars. These flat bars are strong and reliable, making them suitable for a wide range of applications. Explore how mild steel flat bars can benefit your project, from building to manufacturing. This Stavian post emphasizes the durability and versatility of mild steel flat bars, making them an excellent choice for a variety of applications.

Learn more: Stainless Steel Flat Bar: Price Factors and Best Deals

A mild steel flat bar is a type of steel product that is commonly used in construction, manufacturing, and general fabrication. It is made from low-carbon steel, which provides a balance between strength and affordability.

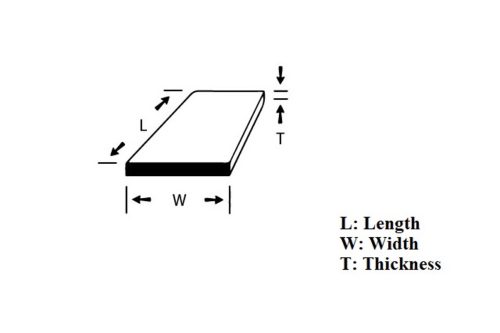

Mild steel flat bars have a rectangular cross-section and come in various widths, thicknesses, and lengths to accommodate different applications. They are known for their versatility and can be easily welded, cut, drilled, and formed into different shapes. This makes them suitable for a wide range of uses, including structural support, brackets, frames, machinery components, and general fabrication projects.

Mild steel flat bars have several qualities that make them useful in a variety of applications:

Mild steel flat bars typically have a tensile strength ranging from 370 MPa to 440 MPa. This strength allows them to bear substantial loads and resist deformation under applied forces.

The yield strength of mild steel flat bars is around 250 MPa to 350 MPa. This property represents the stress level at which the material begins to exhibit permanent deformation.

Mild steel flat bars exhibit excellent ductility, meaning they can be easily bent, formed, and manipulated without significant cracking or fracturing. This property enables them to be shaped into various configurations to suit specific project requirements.

Mild steel flat bars have high weldability, allowing them to be easily joined through welding processes such as arc welding, MIG welding, or spot welding. They form strong and reliable welds when appropriate welding techniques and procedures are followed.

Mild steel flat bars are known for their favorable machinability, which means they can be easily machined, drilled, cut, and shaped using common machining tools and techniques. This property simplifies the fabrication process and allows for precise shaping and sizing.

Mild steel flat bars are one of the most cost-effective options for steel components. The relatively low cost of mild steel, combined with its desirable mechanical properties, makes it a popular and economical choice for various applications.

Mild steel flat bars are widely available in different sizes, thicknesses, and lengths, allowing for easy sourcing and customization to meet specific project needs. They can be easily obtained from steel suppliers and are often stocked in standard sizes for convenience.

Mild steel flat bars are susceptible to corrosion if left unprotected. However, they can be protected from rust and corrosion by applying suitable surface treatments, such as painting, galvanizing, or using protective coatings. These treatments enhance their resistance to environmental factors and extend their lifespan.

It’s important to note that the specific properties of mild steel flat bars can vary depending on factors such as the grade of steel, manufacturing processes, and any additional treatments or coatings applied to the surface.

Mild steel flat bars are available in standard sizes that are commonly stocked by steel suppliers. Here are some typical mild steel flat bars standard sizes in mm :

Thickness: Standard thicknesses for mild steel flat bars typically range from 3 mm to 25 mm or more. Common thicknesses include 3 mm, 5 mm, 6 mm, 8 mm, 10 mm, 12 mm, 15 mm, 20 mm, 25 mm, and larger. These thicknesses provide the required strength and stability for different structural and fabrication purposes.

Width: Commonly available standard widths for mild steel flat bars include 20 mm, 25 mm, 30 mm, 40 mm, 50 mm, 60 mm, 75 mm, 100 mm, 125 mm, 150 mm, 200 mm, 250 mm, 300 mm, and larger. These sizes provide a range of options to suit various applications.

Length: The standard lengths for mild steel flat bars are often 6 meters (approximately 19.7 feet) or 12 meters (approximately 39.4 feet). These lengths are convenient for handling, transport, and general usage. However, it’s worth noting that shorter lengths, such as 3 meters or 4 meters, may also be available, depending on the supplier.

It’s essential to keep in mind that the availability of specific sizes may vary depending on the steel supplier, regional standards, and market demand. Some suppliers may offer a broader range of sizes, including non-standard sizes, while others may focus primarily on standard sizes.

If you have specific size requirements for your project, it is advisable to contact local steel suppliers or manufacturers to inquire about their available sizes and whether they can accommodate any custom sizing needs. They will be able to provide you with more detailed information specific to their product offerings and capabilities.

The weight of a mild steel flat bar can be calculated using the following formula:

Weight (in kilograms) = Width (in meters) x Thickness (in meters) x Length (in meters) x Density of Mild Steel

The density of mild steel is typically around 7.85 grams per cubic centimeter (or 7850 kilograms per cubic meter).

For example, let’s calculate the weight of a mild steel flat bar with the following dimensions:

Width = 30 millimeters

Thickness = 5 millimeters

Length = 1 meter

To begin, we must convert the dimensions to meters:

Width = 30 millimeters = 0.03 meters

Thickness = 5 millimeters = 0.005 meters

Length = 1 meter

Now we can calculate the weight:

Weight = 0.03 meters x 0.005 meters x 1 meter x 7850 kilograms per cubic meter

Weight = 0.000375 cubic meters x 7850 kilograms per cubic meter

Weight = 2.94375 kilograms

So, a mild steel flat bar with a width of 30 mm, thickness of 5 mm, and length of 1 meter would weigh approximately 2.94 kilograms.

The mild steel flat bar prices in Vietnam and on the international market can be influenced by several factors. One significant factor is the cost of raw materials, such as iron ore and scrap metal, which fluctuates based on global supply and demand.

Changes in construction activity, infrastructure development, and manufacturing demand also play a role in shaping the overall steel demand and subsequently affect its price. The production capacity and utilization rates of steel mills impact prices as well. Excess capacity can lead to competitive pricing, while limited capacity or high demand may result in higher prices.

Currency exchange rates and trade policies, including tariffs and trade restrictions, can further influence steel prices, particularly for imported steel. Energy costs associated with production and transportation also contribute to the final price of mild steel flat bars. These factors interact and evolve, leading to fluctuations in prices for mild steel flat bars in both Vietnam and international markets.

Currently, the mild steel flat bars price ranges between $300 and 550 USD per ton.

Before comparing the two varieties of mild steel flat bar and bright mild steel flat bar, let’s define bright mild steel flat bar with Stavian.

Bright mild steel flat bars, also known as bright steel flat bars or bright drawn flat bars, are a specific type of mild steel flat bars. They undergo a cold-drawing process, which improves their surface finish and dimensional accuracy. Bright mild steel flat bars have a smooth and shiny appearance, making them suitable for applications that require an enhanced aesthetic appeal. They are commonly used in architectural projects, decorative applications, furniture manufacturing, and other projects where a clean and polished finish is desired. While they offer similar characteristics to regular mild steel flat bars in terms of strength and versatility, the bright finish sets them apart in appearance.

Composition: Mild steel flat bars are formed of low-carbon steel, which provides a good mix of strength and price. Bright mild steel flat bars, like mild steel flat bars, are formed of low-carbon steel.

Surface Finish: When compared to bright mild steel flat bars, mild steel flat bars have a normal mill finish that may have minor defects and a rougher texture. Bright mild steel flat bars are cold drawn, resulting in a smooth, polished, and shiny surface finish.

Appearance: Due to the mill finish, mild steel flat bars have a dull and matte appearance. Because of the cold-drawing process, bright mild steel flat bars have a clean and visually pleasant look.

Uses: Mild steel flat bars are extensively utilized in building, manufacturing, and general fabrication applications where aesthetics are secondary. Bright mild steel flat bars are often utilized in architectural projects, ornamental applications, furniture production, and other tasks that require a polished and appealing appearance.

Availability: Mild steel flat bars are widely available in a variety of widths, thicknesses, and lengths. Bright mild steel flat bars come in a variety of widths, thicknesses, and lengths, but they are less regularly stocked than standard mild steel flat bars.

In summary, while both mild steel flat bars and bright mild steel flat bars are made of low-carbon steel, the main distinction is in their surface quality and look. Mild steel flat bars have a basic mill finish and are suited for general applications, whereas bright mild steel flat bars are cold-drawn to give a polished and appealing finish, making them perfect for applications requiring improved visual appeal.

Learn more

High-Quality Steel Flat Bars at Competitive Prices for Your Project

In conclusion, the mild steel flat bar is a durable and versatile metal that finds application in various industries and projects. Its strength and resilience make it suitable for structural purposes, while its flat shape and easy machinability allow for versatility in fabrication and construction. Whether used in building frameworks, machinery parts, or general fabrication, mild steel flat bars offer reliability and cost-effectiveness. With a wide range of standard sizes available, they can be tailored to suit specific project requirements. As a durable and versatile metal, the mild steel flat bar continues to be a popular choice for diverse applications, providing strength and stability in numerous projects.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com