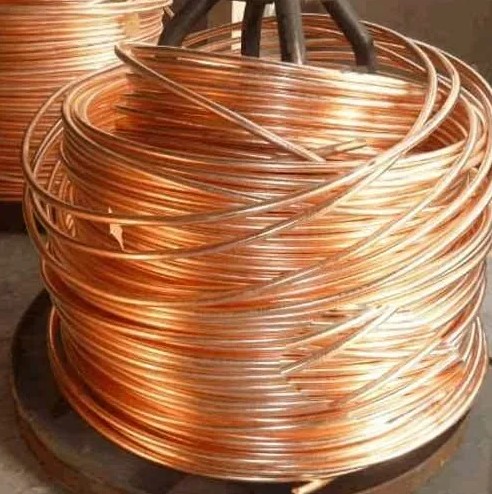

Looking for a durable and high-performance solution for electrical and industrial applications? The 2mm copper wire stands out as a reliable conductor, known for its excellent electrical conductivity, flexibility, and resistance to corrosion. At Stavian Industrial Metal, we provide top-grade 2mm copper wire tailored to meet the demanding standards of construction, automotive, and energy industries. With consistent quality and precise specifications, our copper wire ensures optimal performance, long service life, and easy integration into various systems. Whether you’re sourcing for large-scale manufacturing or small electrical projects, our 2mm copper wire delivers unmatched efficiency and value.

One of the most common uses of 2mm copper wire is in electrical and power distribution systems. Due to its excellent electrical conductivity, copper remains the material of choice for both residential and industrial wiring. The 2mm diameter strikes a balance between flexibility and current-carrying capacity, making it ideal for medium-load circuits, grounding applications, and control wiring.

In residential settings, 2mm copper wire is frequently used in internal wiring for lighting, outlets, and appliance connections. Its stable conductivity ensures minimal voltage drops across distances, improving the overall safety and performance of electrical systems. In commercial and industrial infrastructures, it plays a critical role in control panels, power circuits, and automated systems.

Moreover, copper’s resistance to heat and corrosion allows 2mm copper wire to maintain its performance in demanding environments. Installers and engineers often prefer this size for its ease of handling and consistent current flow, helping to reduce the risk of overheating and energy loss in critical systems.

The automotive industry increasingly relies on copper wiring due to the growing complexity of vehicle electronics. Within this context, 2mm copper wire is particularly useful for supplying power to major electrical components such as lighting systems, control units, power windows, and infotainment systems. Its flexibility and strength make it suitable for tight installation spaces and areas exposed to vibration and mechanical stress.

In electric and hybrid vehicles, where electrical performance is paramount, 2mm copper wire is used in battery management systems and high-load energy circuits. Its high conductivity ensures that components receive the necessary voltage levels efficiently, improving overall vehicle reliability and energy efficiency.

Public transportation systems, including buses and trains, also benefit from the reliability of copper wiring. The 2mm size serves applications requiring durable and efficient wiring over long distances, helping maintain consistent power across critical systems like braking, communication, and air conditioning.

Copper is universally acknowledged for its exceptional conductivity. A 2mm copper wire offers low resistance, enabling efficient transmission of electricity with minimal energy loss. This is particularly important in both residential and industrial settings, where long-term energy efficiency contributes to cost savings and environmental sustainability.

The thermal conductivity of copper is another critical advantage. In systems where overheating can lead to failures or hazards, copper helps dissipate heat more effectively than most other metals. This property ensures stable operation in circuits with high electrical loads, prolonging the life of both the wire and connected components.

Engineers and project designers favor copper wiring over alternatives like aluminum due to its superior performance in both low and high-temperature environments. The 2mm variant provides an ideal compromise between material cost and electrical efficiency, making it a smart investment for long-term reliability.

Apart from conductivity, 2mm copper wire is valued for its mechanical robustness. Its tensile strength allows it to withstand bending, stretching, and external pressure during installation and operation. This mechanical integrity is crucial in industrial settings, where wires may be subjected to mechanical vibrations or physical impact.

Copper’s natural resistance to oxidation and corrosion also makes it suitable for use in outdoor and high-humidity environments. Even without additional coatings, 2mm copper wire retains its conductive properties and physical form, reducing maintenance requirements and replacement costs over time.

In marine and underground applications, where exposure to moisture and corrosive agents is unavoidable, copper remains the preferred material. Its long-term stability and durability ensure continuous performance, even under challenging environmental conditions.

To ensure safety and performance, 2mm copper wire must adhere to rigorous manufacturing standards. International bodies such as the ASTM (American Society for Testing and Materials), IEC (International Electrotechnical Commission), and UL (Underwriters Laboratories) provide comprehensive guidelines for wire composition, diameter tolerance, conductivity, insulation, and mechanical properties.

At Stavian Industrial Metal, we ensure our 2mm copper wire meets or exceeds these global standards. Each batch is tested for purity—typically requiring a copper content of 99.9% or higher—to ensure optimal conductivity. Dimensional accuracy is also maintained through precision drawing processes that control the wire diameter within tight tolerances.

Compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is also critical, especially for customers operating in regulated markets like the European Union. By aligning with these standards, we provide products that are safe, environmentally responsible, and suitable for a global customer base.

Quality control is essential in maintaining the performance and reliability of 2mm copper wire. During the production process, wires undergo a series of inspections, including:

These processes are carried out under stringent quality control protocols, allowing our 2mm copper wire to consistently perform in demanding environments.

When selecting a 2mm copper wire, understanding the difference between solid and stranded constructions is vital. Solid copper wire consists of a single copper conductor and is ideal for fixed installations where the wire will not be subject to frequent movement. It offers superior conductivity and is easier to install in straight runs or inside walls.

On the other hand, stranded copper wire is made from multiple smaller strands twisted together. This type offers greater flexibility, making it suitable for applications involving vibrations, movement, or tight bends—such as in automotive wiring or machinery.

Each type has its specific use case:

Choosing the correct type depends on the mechanical demands of the application and the required ease of installation.

Another important consideration is whether to use bare or tinned copper wire. Bare copper wire is uncoated and offers maximum conductivity. It is typically used indoors where corrosion is less of a concern. However, in humid, marine, or chemically active environments, tinned copper wire provides an advantage.

Tinning involves coating the copper strands with a thin layer of tin to enhance corrosion resistance. While it slightly increases resistance compared to bare copper, it significantly extends the wire’s lifespan in challenging environments.

Understanding the installation environment helps determine the appropriate choice:

At Stavian Industrial Metal, quality begins with raw materials. We source premium-grade copper with high purity levels to ensure consistent electrical performance. Our strict material screening processes eliminate impurities that could affect conductivity or durability.

Each wire is manufactured using advanced drawing and annealing techniques, optimizing the balance between strength and flexibility. This ensures that our 2mm copper wire meets the most demanding requirements for voltage transmission, mechanical stress, and thermal stability.

Furthermore, our product offerings include customization for specific insulation types, spool sizes, and packaging to meet the unique needs of various industries. Whether for OEM manufacturing or construction projects, our copper wire solutions deliver lasting value.

Stavian Industrial Metal operates with a global logistics network, enabling timely delivery of 2mm copper wire to clients across continents. We maintain substantial inventory levels, ensuring we can support both small and large-volume orders with quick turnaround times.

In addition to product supply, we offer expert technical support. Our engineering team assists clients in selecting the right copper wire specification, conducting feasibility analysis, and ensuring compliance with industry standards. This consultative approach reduces risks and enhances the efficiency of client operations.

By partnering with Stavian Industrial Metal, customers gain access not just to a product, but to a full-service copper wire solution supported by industry-leading expertise.

Address

Website: https://stavianmetal.com

Email: info@stavianmetal.com