| CATEGORIES | DETAILS |

| Size | Nominal size : 120×120mm, 130×130mm,150×150mm Length: 6/12m |

| Grade | CT5, 3SP, 4SP, 5SP, SD295(A)… |

| Standard | JIS, ASTM, BS, TCVN… |

Steel Billet

Steel billets distributed by Stavian Industrial Metal.,JSC are manufactured in large-scale factories, invested in building a closed and synchronous production complex to create a continuous chain in the production of billets and finished steel.

We supply a variety of steel billets, produced by IF, EAF, and BF technology, meeting customers’ requirements. Especially, customized products in large quantities are available upon customers’ request.

0 ₫

Steel billets, an essential component in the industry and construction sectors, play an indispensable role in creating high-quality steel products. From massive structures to small details in our daily lives, steel billets have contributed significantly to our construction and development. Today, we will explore this type of material and its diverse applications.

What Are Steel Billets?

Steel billets are a form of raw steel that is not used directly. They need to be cast into new shapes before being utilized for various purposes.

After being extracted from mines, ores are transported to integrated steel production facilities for the production of steel billets. The process of producing steel billets involves stages such as extraction, melting, steel rolling, and the creation of finished products.

In terms of chemical composition, steel billets primarily consist of iron (Fe) and carbon. They also contain elements like silicon (Si), sulfur (S), phosphorus (P), manganese (Mn), and other trace elements to enhance specific mechanical properties or unique characteristics for particular applications.

Before being brought to the market, steel billets must be processed and cut into parts that match the required dimensions. This gives them a clear and distinctive grain structure, enabling the metal to be machined and flexible. In addition, steel billets are cost-effective and readily accessible in most areas.

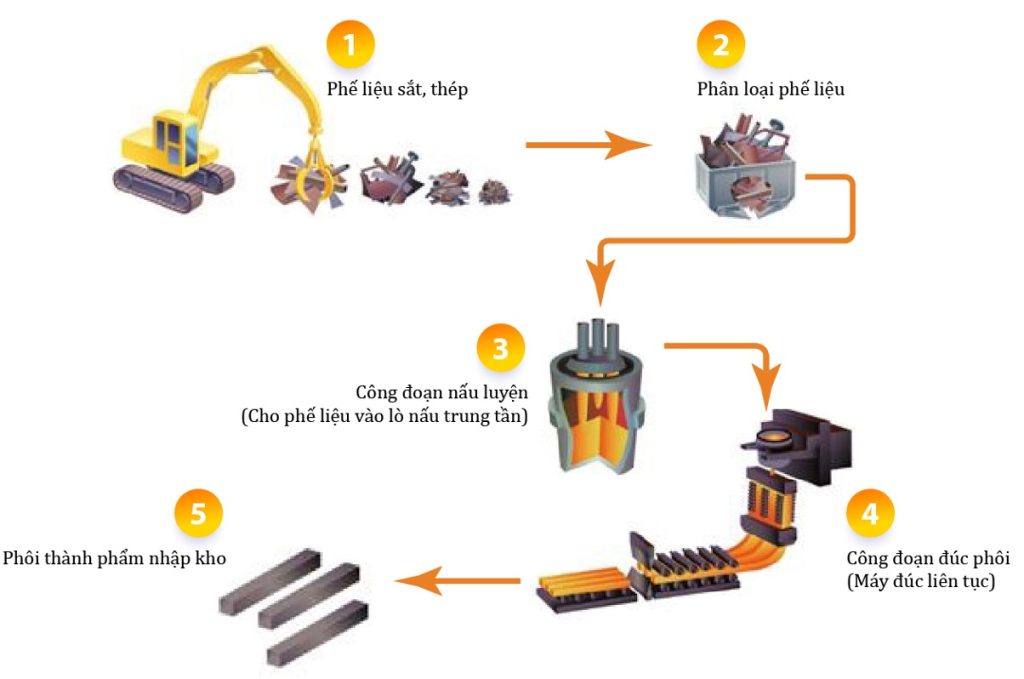

Steel Billet Production Process

There are two main methods used to produce steel, namely:

- Production through a Basic Oxygen Furnace (BOF) and

- Production through an Electric Arc Furnace (EAF).

Both of these methods have their own advantages and applications, depending on the scale, quality requirements, and available raw materials.

Currently, on a global scale, steel production is primarily carried out through the basic oxygen furnace (BOF) process, which consists of three main steps:

- Step 1: Iron ore is extracted from mines and then transported to production facilities.

- Step 2: The iron ore raw materials are introduced into a smelting furnace to melt into a hot molten metal stream at the required temperature. This molten metal stream is then transferred to an electric arc furnace to remove impurities and adjust the composition to produce the desired steel grade.

- Step 3: After impurities are removed, the molten metal is cast into various types of steel billets such as square billets, slab billets, and bloom billets. These steel billets are then used in shaping machines to produce different steel products, including construction steel, structural steel, rolled steel, steel plates, and many other types.

This steel production process through the basic oxygen furnace plays a crucial role in supplying and manufacturing a variety of steel products to serve different industries worldwide.

Steel Billet Status:

Hot State:

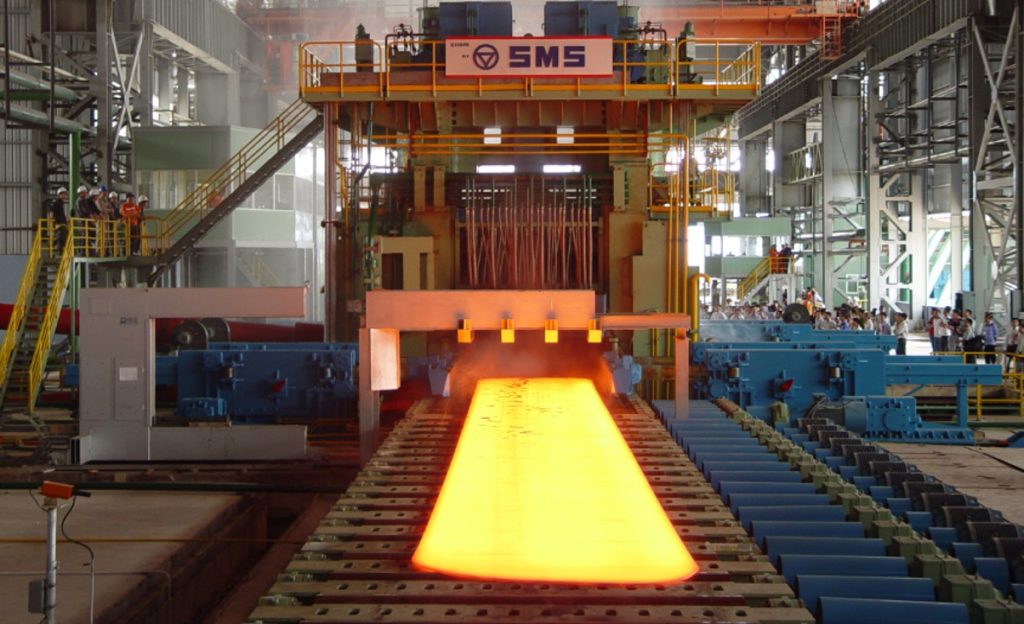

The hot state of steel billets is when the billet is heated to a high temperature. It is then directly put into the hot rolling process without undergoing a cooling process. This process is typically applied when there is a need to create steel products with high ductility, easy bending, and complex shapes.

Hot steel billets are rolled at high temperatures, producing products with the desired thickness and dimensions. This process helps increase the softness and ductility of the steel, while also improving its uniformity and metal structure.

Cool State:

The cool state of steel billets occurs after the melting and hot rolling process. After being formed and cast into various types of billets such as square billets, flat billets, or bloom billets, the steel billet will be naturally cooled or cooled using processes like liquid cooling or air cooling.

This cooling state involves gradually cooling the metal, allowing it to achieve the desired hardness and mechanical properties. The cooling process can be controlled to create specific structures and properties of the steel product, such as hardness, ductility, and uniformity.

Types of Steel Billets:

Square Billets

Square billets are primarily used to produce rolled steel and ribbed steel bars. They are especially widely used in the construction industry.

Square billets come in various sizes and shapes, but they are typically in a square cylindrical form. Common sizes for square billets include 100 x 100, 125 x 125, and 150 x 150. The length of square billets can range from 6m to 12m, depending on the standards of the plant or industry.

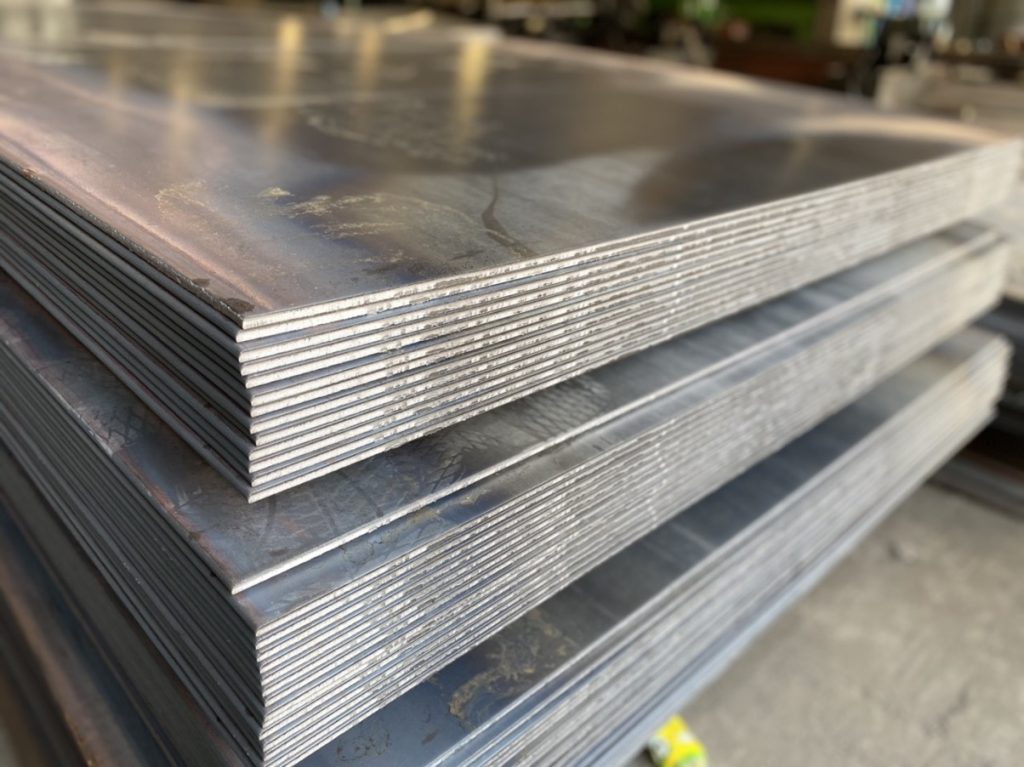

Flat Steel Billet:

Flat steel billet has a rectangular shape with two long edges and two short edges. It is produced by either hot rolling or cutting from large steel plates. Flat steel billets typically have a uniform thickness across the entire surface. This makes it suitable for cutting, processing, and using in various applications. It is widely used in the construction, mechanical, manufacturing, and industrial industries.

Steel Bloom:

Steel bloom is a type of steel billet with a long and narrow rectangular shape. Similar to flat steel billet but larger in size, steel bloom is produced by casting molten metal into special molds. Steel bloom typically has large dimensions, allowing it to be processed and shaped into large steel products such as machine shafts, ship shafts, bridge girders, and significant industrial components. Steel bloom is primarily used in heavy industries and the construction of large structures.

Square Steel Billet:

Square steel billet shares similar characteristics with flat steel billet but is significantly larger in size compared to flat billets. This type of billet is used to manufacture various finished construction steel products such as square steel tubes, steel profiles, steel pipes, steel bars, steel coils, and similar products.

Round Steel Billet:

Round steel billet has a high carbon content, making it resistant to corrosion due to oxidation. It also exhibits good heat resistance and high tensile strength in environments with continuous temperature variations.

Applications of steel billets

Steel billets have many applications in various fields. Below are some common applications of steel billets:

Construction and architecture: Steel billets are widely used in the construction industry. They are used to create columns, beams, steel frames, girders, steel plates, and other structural components. They provide high load-bearing capacity and strength, helping to build structures such as bridges, buildings, factories, and mines.

Mechanical and manufacturing: Steel billets are used in the mechanical and manufacturing industries to produce machine parts, industrial equipment, and mechanical tools. Products include machine shafts, ship shafts, bolts, screws, springs, gears, and other load-bearing components.

Automotive and transportation: In the automotive and transportation manufacturing industry, steel billets are used to manufacture vehicle frames, suspension components, bolts, exhaust pipes, and other components. The load-bearing capacity and strength characteristics of steel billets ensure the safety and reliability of vehicles.

Electronics and refrigeration: Some types of steel billets, such as stainless steel, are used in the electronics and refrigeration industries to manufacture parts such as washing machine casings, refrigerators, heat exchanger tubes, and electrical contact components.

Additionally, steel billets are also used in many other fields such as the petroleum and natural gas industry, maritime industry, food industry, and more.

Benefits of Using Steel Billets

High Strength and Load-Bearing Capacity

Steel billets offer several important benefits when used in various industries. Firstly, their high strength and load-bearing capacity are crucial factors. With the ability to withstand high pressure and heavy loads, steel billets are used in construction and mechanical applications to ensure safety and durability for structures.

Reasonable Cost and Market Availability

Another advantage is the reasonable cost and market availability. Steel billets are an economically valuable material. They are produced on a large scale and are available in diverse supply sources. This helps reduce production and construction costs, making steel billets a popular and cost-effective choice for construction projects.

Ease of Machining and Welding

Additionally, steel billets have the advantage of being easy to machine and weld. Their flexibility and ability to withstand machining and welding processes allow for the production of a wide range of products in various shapes and sizes. This opens up many creative and flexible opportunities in designing and manufacturing products from steel billets.

What Factors Typically Affect Steel Billet Prices?

- Prices of Primary Raw Materials: Steel billet prices are significantly affected by the prices of primary raw materials, such as iron ore and coking coal. Increases in raw material prices tend to drive up steel billet prices.

- Market Supply and Demand: Market supply and demand conditions have a significant impact on steel billet prices. If demand exceeds supply, steel billet prices may rise, and vice versa.

- Production Cost Changes: Changes in production costs can influence steel billet prices. Costs related to transportation, storage, and handling of steel billets can also affect the final product’s price.

- Economic Conditions: The economic conditions of a country or region can influence steel billet prices. During economic downturns, steel billet prices tend to decrease.

- Exchange Rate Fluctuations: Changes in exchange rates can affect steel billet prices by impacting the cost of importing raw materials or altering export prices.

- Trade Policies and Tariffs: Trade policies, customs duties, and other factors related to international trade can also impact steel billet prices.

With its high strength, load-bearing capacity, reasonable cost, and versatile machining capabilities, steel billets have been widely used in various fields of life and the economy. From construction and mechanical engineering to the manufacturing industry and many other sectors, steel billets have demonstrated their crucial role in the development of society.

Today’s Steel Billet Prices

- The price of construction steel today ranges from 13,150 VND/kg to 15,200 VND/kg.

- The price of construction steel in the South today is 14,250 VND/kg.

- The price of construction steel from Viet Duc today is 13,350 VND/kg.

- The price of construction steel from Tisco today is 14,200 VND/kg.

- The price of construction steel from Viet Nhat today is 15,200 VND/kg.

- The price of construction steel from Pomina today is 14,300 VND/kg.

- The price of construction steel from Hoa Phat today is 13,650 VND/kg.

- The price of construction steel from Viet Uc today is 13,650 VND/kg.

- The price of construction steel from Viet Y today is 13,300 VND/kg.

- The price of construction steel from Viet My today is 13,250 VND/kg.

- The price of construction steel from Tung Ho today is 13,450 VND/kg.

- The price of construction steel from ASEAN ASC (Southeast Asia) today is 13,150 VND/kg.

*Source: Stavian Industrial Metal, collected from the Internet

If you have a need for these products or require advice on suitable products, please contact us via the Hotline: ‘+84 2471001868 / +84975271499 for timely assistance!

View more other products

Contact form