| Categories | Details |

| Grade | SD295, SD390, SD490, CB300-V, CB400-V, CB500-V, Gr60, Grade 460… |

| Diameter | D06 – D50mm |

| Application | In the construction of concrete, reinforced concrete, civil houses, industrial buildings, office buildings, bridges and roads, hydroelectric projects… |

| Standard | BS, ASTM, JIS… |

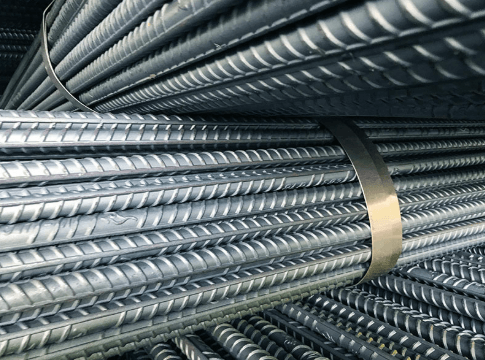

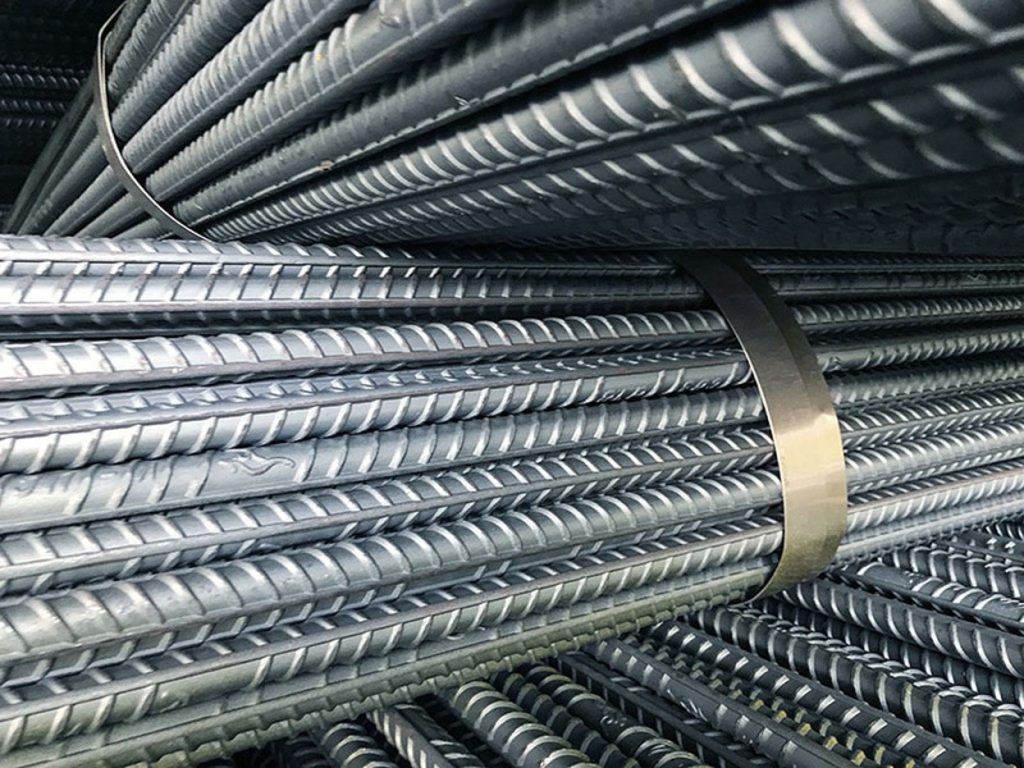

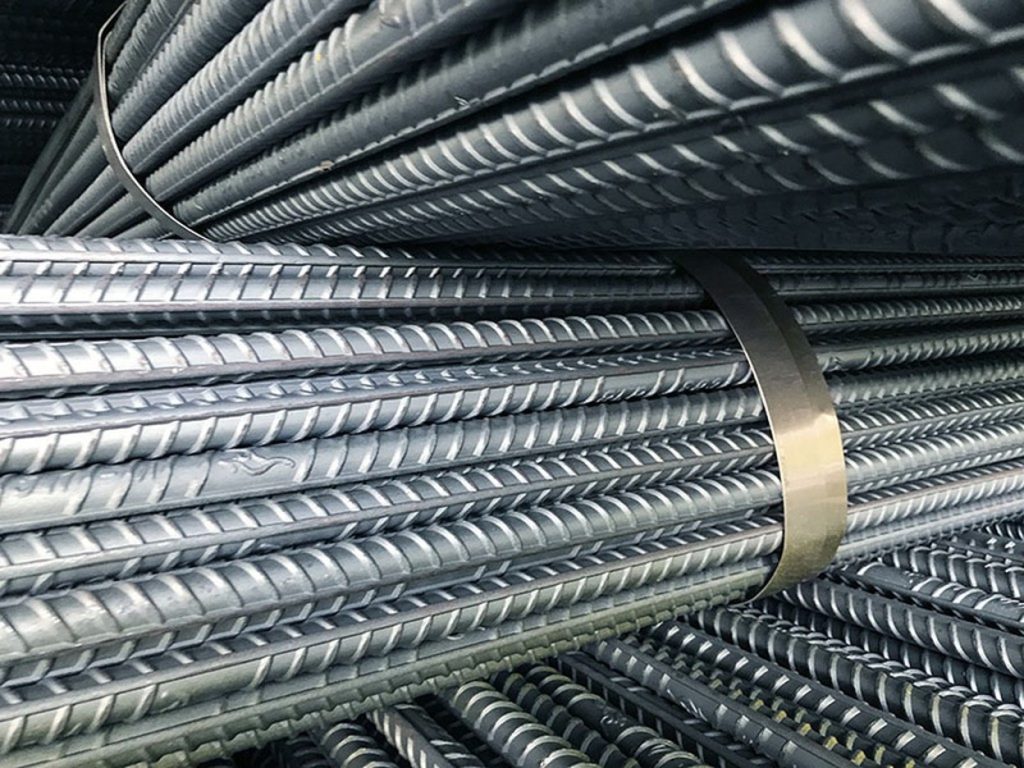

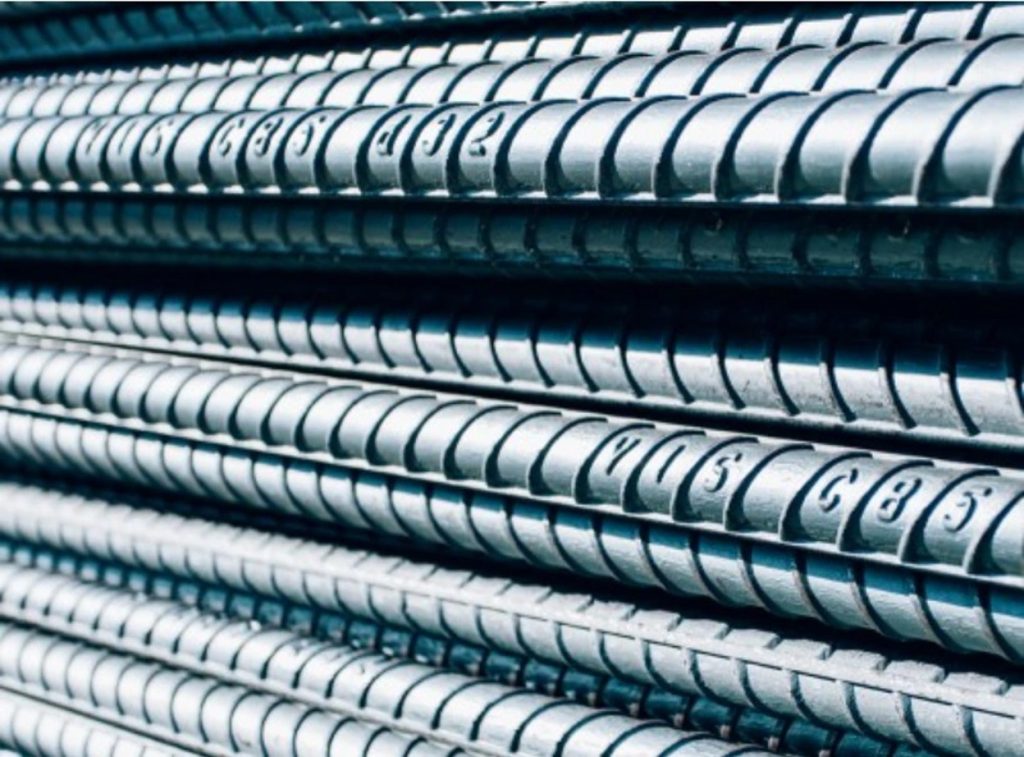

Rebar Steel

All rebar products provided by Stavian Industrial Metal.,JSC have transparent origins and quality assurance in accordance with the technical standards of reputable manufacturing plants in Vietnam and worldwide.

0 ₫

With its outstanding properties and good load-bearing capacity, ribbed steel bars have become a preferred choice for various construction projects. From civil engineering to industrial constructions, ribbed steel bars play a crucial role in creating sturdy and safe structures. In this article, we will explore ribbed steel bars, from their definition and structure to their applications and important considerations when selecting and using them.

What Are Ribbed Steel Bars?

Ribbed steel bars, also known as ribbed reinforcement steel or reinforced concrete steel, are characterized by having multiple diagonal protruding ribs along the length of the steel bar, resembling fishbones.

Ribbed steel bars typically have diameters ranging from 10mm to 55mm and are in the form of bars with a standard length of 11.7 meters. However, they can also be manufactured according to customer requirements. Ribbed steel bars are bundled into batches, with each batch weighing between 1500kg and 3000kg, depending on its size.

Various parameters such as dimensions, cross-sectional area, weight per meter length, allowable deviations, and other quantities need to be calculated as per specific standards.

Classification of Ribbed Steel Bars

There are several types of ribbed steel bars with small to medium diameters, including 10mm, 12mm, 14mm, 16mm, 18mm, and 20mm. These correspond to ribbed steel bar diameters of d10, d12, d14, d16, d18, and d20, respectively. These types are widely used in residential construction, high-rise buildings, roads, bridges, and various other construction projects. Additionally, 8mm ribbed steel bars (d8 ribbed steel) are also commonly applied in various industries.

Furthermore, there are special types of ribbed steel bars with larger diameters, including 22mm, 25mm, 28mm, and 32mm, corresponding to diameters of 22mm, 25mm, 28mm, and 32mm. These types are often used in large-scale projects with high technical requirements. Additionally, ribbed steel bars with diameters of up to 55mm can be produced depending on construction requirements.

What Are the Outstanding Advantages of Ribbed Steel Bars?

Strength and High Load-Bearing Capacity: Ribbed steel bars possess superior mechanical properties, ensuring the ability to withstand large loads and high durability. This enhances safety and stability for construction projects.

Ease of Processing and Flexible Installation: They are easy to work with, allowing for simple machining, cutting, welding, and bending to meet design requirements. This saves time and effort during installation.

Stability and High Precision: Ribbed steel bars are manufactured with precision processes, ensuring consistent dimensions and shapes. This guarantees stability and accuracy in construction projects.

Fire Resistance and Sustainability: Ribbed steel has better fire resistance and heat resistance compared to other materials like wood. Additionally, ribbed steel bars have high recyclability, promoting sustainability and environmental protection by facilitating recycling and reuse in the manufacturing process.

Versatility in Applications: Ribbed steel bars are widely used in both civil and industrial construction projects. They are used in residential houses, high-rise buildings, bridges, tunnels, and large industrial structures. With a variety of types and sizes, they can accommodate various design requirements and applications.

Applications of Ribbed Steel Bars in the Construction Industry

Residential Construction:

Ribbed steel bars are used to construct columns and beams in residential buildings, villas, high-rise buildings, warehouses, and public structures. Additionally, they are employed in creating ceiling and floor structures, enhancing load-bearing capacity and durability for construction projects.

Industrial Construction:

Ribbed steel bars are the primary material used in constructing warehouses and industrial plants. They are utilized to build framework structures, industrial equipment, and foundation systems. This includes items such as cranes, scaffolding, drilling rigs, and infrastructure systems within manufacturing facilities.

Utilized in Bridges and Mining Tunnels:

Ribbed steel bars are employed to construct the structures and frameworks of bridges, including main girders, supports, and load-bearing beams. Furthermore, they are used to create support structures and reinforcement within mining tunnels and underground constructions.

How to Preserve Ribbed Steel Bars?

To ensure the durability and appearance of construction steel, you can implement the following measures:

Storage in a Dry Environment:

Construction steel should be stored in a dry environment, avoiding direct contact with moisture and exposure to the elements. You can use moisture-resistant packaging or apply anti-corrosion coatings to protect against moisture and oxidation.

Avoid Contact with Corrosive Liquids:

Construction steel should not come into direct contact with corrosive liquids such as acids, alkalis, or salts. If there is contact, clean the steel surface thoroughly and use protective coatings to prevent the effects of the liquid.

Regular Inspection and Maintenance:

Regularly inspect the condition of construction steel to detect early signs of damage or corrosion. At the same time, perform routine maintenance measures such as replacing peeling paint layers, cleaning the surface, and protecting against impacts or breakage.

Factors to Consider When Choosing and Using Ribbed Steel Bars:

Quality and Standard Assessment:

When selecting ribbed steel bars, it is important to consider the quality and standard assessment of the product. Choose a reliable supplier and ensure that the steel meets the quality standards and regulations of the construction industry. Check for quality certificates, certification, and the origin of the product to ensure the reliability and performance of ribbed steel bars.

Load-Bearing Capacity and Structural Calculations:

Before using ribbed steel bars, it is essential to accurately determine the load-bearing capacity and calculate the structure of the project. This includes specifying the steel’s load-bearing requirements and correctly calculating the applied forces. Ensure that the structure is designed and used safely and effectively.

Product Quality Control:

During the use of ribbed steel bars, product quality control is crucial. Ensure that the bars are free from manufacturing defects, scratches, or deformations. Check technical specifications such as dimensions, thickness, and surface smoothness to ensure the quality and durability of the steel. If any issues are detected, take corrective measures or replace them to ensure the safety and reliability of the structure.

Ribbed Steel Bar Prices:

Ribbed steel bar prices can vary depending on several factors, including supply and demand, fluctuations in raw material prices, production costs, market regulations, and general economic factors.

In some cases, ribbed steel bar prices may increase significantly due to supply shortages, rising raw material costs, or other factors affecting production costs. Additionally, economic and market factors can also impact prices.

Reputable and Quality Ribbed Steel Bar Suppliers:

Stavian Industrial Metal Joint Stock Company always provides high-quality ribbed steel bars with excellent strength, load-bearing capacity, and long-term durability, ensuring industry standards and regulations are met.

Furthermore, we offer various types of ribbed steel bars to meet customer needs. We have a wide range of sizes, shapes, and structures to meet various construction requirements at highly competitive prices.

Alongside this, we have a team of professional consultants and customer-oriented purchasing policies, providing customers with peace of mind when choosing Stavian’s products.

View more other products

Contact form