| CATEGORIES | DETAILS |

| Grades | Al99.90/Al99.85/Al99.70/Al99.60… Al 99-99.9% min. Others: Al96 or ADC-6, ADC-12/A-413, A-360… |

| Appearance & Weight | Silvery white color, approximately 20-25 kg per ingot, or as per specific standards of each manufacturer |

Aluminum Ingot

Stavian Industrial Metal.,JSC provides high-quality aluminum ingots which are raw materials for the production of aluminum alloys (aluminum billet) and final aluminum profiles.

All products offered by Stavian Industrial Metal.,JSC are well-sourced and trusted by domestic and foreign markets.

0 ₫

Aluminum Ingot provides many benefits to users, from its lightweight and durability to its corrosion resistance and heat resistance. Additionally, it is known for its recyclability and environmental friendliness. So, what exactly is aluminum ingot, and in which industries is it used? Where can you buy reliable aluminum ingots? All of this will be covered in the article below. Let’s take a look.

What is Aluminum Ingot?

Aluminum ingot is a type of pure aluminum compound that is cast into specific-sized and shaped solid blocks. Aluminum ingots play a vital role in various industries due to their unique properties.

The Aluminum Ingot Production Process

The aluminum ingot production process involves several main steps from raw material processing to the final machining.

Firstly, necessary raw materials, such as aluminum ore and aluminum alloys, are collected and mined. The aluminum ore is then processed to separate aluminum from other minerals. Subsequently, refined aluminum is introduced into melting furnaces to create a liquid form.

Next, the liquid aluminum is poured into casting molds and left to cool gradually, forming aluminum ingots. This process needs to be carefully controlled to ensure the quality and purity of the ingots. Once completely cooled, aluminum ingots are removed from the casting molds and further processed into various products such as aluminum sheets, aluminum pipes, or machine components.

Classification of Aluminum Ingot

Aluminum ingots can be classified based on various criteria. Below are some common classifications of aluminum ingots:

By Alloy:

Pure Aluminum Ingot: This type of aluminum ingot is cast with pure aluminum and does not contain any alloys.

Aluminum Alloy Ingot: Aluminum alloy ingots are processed from aluminum alloys with the addition of other elements such as copper, zinc, silicon, magnesium, etc. Aluminum alloy ingots are typically used to enhance hardness, durability, heat resistance, or other specific properties of aluminum to suit particular applications.

By size and shape:

Round Aluminum Ingot: This type of aluminum ingot is round in shape. It is commonly used for manufacturing pipes, shafts, and similar-shaped products.

Rectangular/Square Aluminum Ingot: This type of aluminum ingot has a rectangular or square shape. It is typically used for producing aluminum sheets, aluminum bars, and rectangular or square-shaped products.

The classification of aluminum ingots helps users and manufacturers identify and select the appropriate type of aluminum ingot for their specific requirements and applications. Different types of aluminum ingots have unique properties and characteristics, allowing them to meet various technical requirements and usage purposes.

Advantages of Aluminum Ingot

Aluminum ingot offers several significant advantages, making it a preferred material in various industries. Here are some key advantages of aluminum ingot you should know:

Lightweight and Durable:

One of the main advantages of aluminum ingot is its lightweight nature. Aluminum weighs only about 1/3 of the weight of steel, reducing the overall weight of products. However, aluminum ingot still maintains high durability and good load-bearing capacity, making it an ideal choice for manufacturing in industries such as aerospace, automotive, and transportation.

Corrosion Resistance and Heat Tolerance:

Aluminum ingot has excellent corrosion resistance and does not easily oxidize. This makes it suitable for applications in humid environments, such as construction and the chemical industry. Additionally, aluminum ingot exhibits good heat tolerance, remaining unaffected or deformed when exposed to high temperatures. Therefore, it is suitable for applications requiring heat resistance, such as the electrical and electronic industries.

Recyclability and Environmental Protection:

Another advantage of aluminum ingot is its high recyclability. Aluminum can be efficiently recycled without losing its original properties. This helps conserve natural resources and energy. The use of recycled aluminum ingot also reduces waste and pollution emissions into the environment, contributing to environmental protection and sustainable development.

Applications of Aluminum Ingot

Aluminum ingot finds a wide range of applications in various industries. Here are some common applications of aluminum ingot:

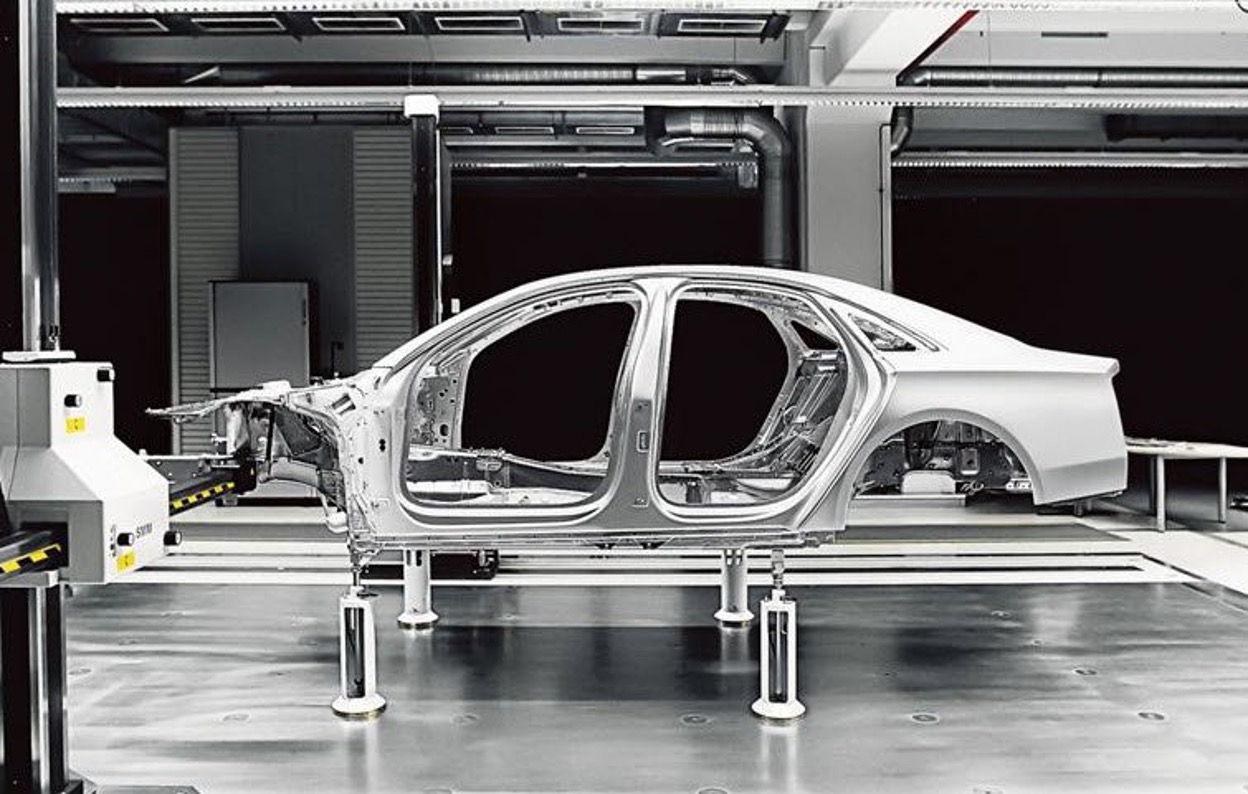

Automotive and Aerospace Industry:

Aluminum ingot is widely used in the manufacturing of automobiles and aircraft. It is used for making vehicle frames, engines, suspension components, aircraft shells, engine enclosures, and other parts. Its lightweight and durability characteristics help reduce overall vehicle weight, improve fuel efficiency, and enhance performance.

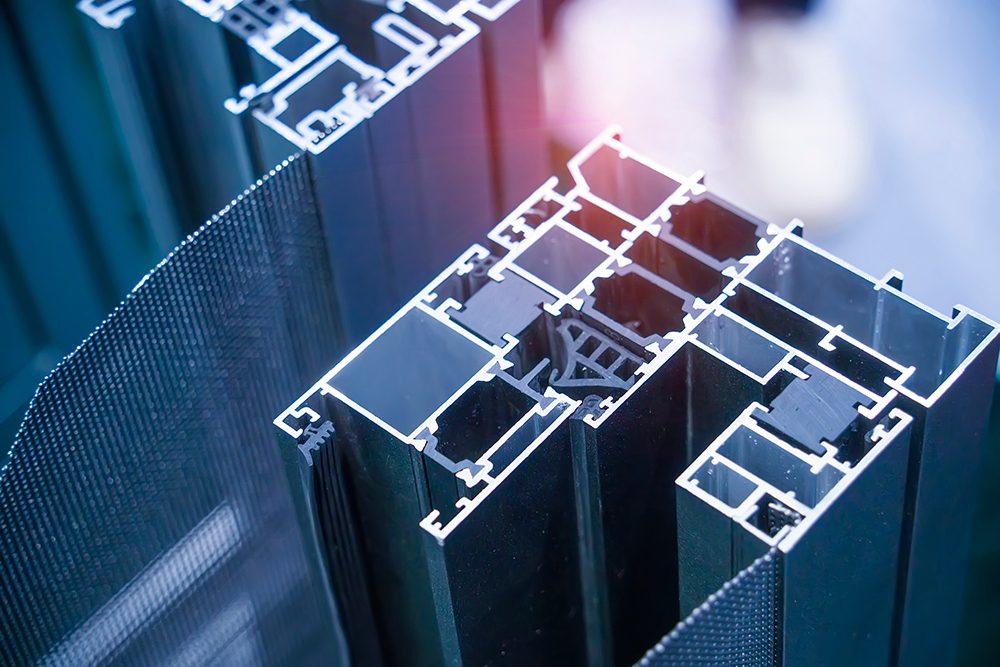

The Construction and Architecture Industry:

Aluminum ingot is used to manufacture construction products such as windows, doors, partitions, aluminum roofing and siding panels, staircases, railings, and curtain wall systems. Its corrosion resistance and ease of processing make it suitable for construction applications, providing a modern and aesthetic appearance to architectural structures.

Electrical and Electronics Industry:

Aluminum ingot is utilized in the production of electrical and electronic equipment. It is used to make transmission lines, heat sinks, protective enclosures, and various other components. Its good electrical conductivity and heat dissipation properties make it ideal for electrical transmission and cooling of electronic devices.

Food Processing and Packaging Industry:

Aluminum ingot finds application in the food and beverage processing industry. It is used to manufacture aluminum cans, aluminum containers, and aluminum beverage packaging. Aluminum ingot is non-toxic and corrosion-resistant, aiding in the preservation and protection of products during transportation and storage.

Other Industrial Applications:

Aluminum ingot also has applications in various other industries such as metal casting, industrial machinery and equipment manufacturing, energy production, the chemical industry, and tool manufacturing. Its ease of processing, flexibility, and corrosion resistance make it suitable for diverse industrial applications.

Challenges in the Aluminum Ingot Manufacturing Industry:

The aluminum ingot industry faces several challenges and opportunities in the current environment. Here are some important aspects to consider:

Competition with Other Materials:

A key challenge in the aluminum ingot industry is competition with other materials like steel, iron, and plastics. These materials also have their own advantages, such as high strength, low cost, or flexibility. To enhance competitiveness, the aluminum ingot industry needs to identify its unique and superior applications. Additionally, optimizing the use of aluminum ingot in various industries is essential.

Production Processes and Technology:

Another critical factor is the production processes and technology in the aluminum ingot industry. Production processes must ensure the quality and reliability of the product. Technology also plays a vital role in improving performance and reducing production costs. To address this challenge, businesses and research organizations need to invest in research and development of new technologies. This can lead to higher-quality aluminum ingot products and optimal performance.

Enhancing Research and Development:

To leverage opportunities in the aluminum ingot industry, there is a need to strengthen research and development activities. Innovation and technological improvements can enhance the properties and performance of aluminum ingot, lead to new applications, and expand the market. Collaboration between businesses, research organizations, and government agencies is crucial in promoting research and development in the aluminum ingot industry.

Where to Buy Reliable and High-Quality Aluminum Ingot:

Stavian Industrial Metal is a reputable company in the metal industry committed to providing high-quality aluminum ingot. They ensure compliance with industry standards and technical requirements.

Stavian Industrial Metal also offers a variety of aluminum ingot types to meet customer needs. You can find different sizes, shapes, and aluminum alloys at this company.

With an experienced and knowledgeable team of metal industry professionals, Stavian Industrial Metal provides professional, dedicated consulting services. They assist you in choosing the right product for your requirements.

Furthermore, after making a purchase, you will receive post-sales support to ensure customer satisfaction.

If you are interested or have a need for aluminum ingot products, please contact us to receive product information and pricing quickly and easily. You can proceed with ordering with confidence.

Contact information:

Stavian Industrial Metal Joint Stock Company

Address: No.508 Truong Chinh Street, Nga Tu So Ward, Dong Da District, Hanoi City

Website: https://stavianmetal.com/

Hotline: +84 2471001868 / +84975271499

Email: info@stavianmetal.com

View more other products

Contact form